Ceramics-imitated plate used for construction

A technology of ceramic panels for construction, which is applied in the field of building decoration materials, can solve the problems of high cost, high energy consumption, and heavy quality, and achieve the effect of good thermal insulation, low production cost, and durable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

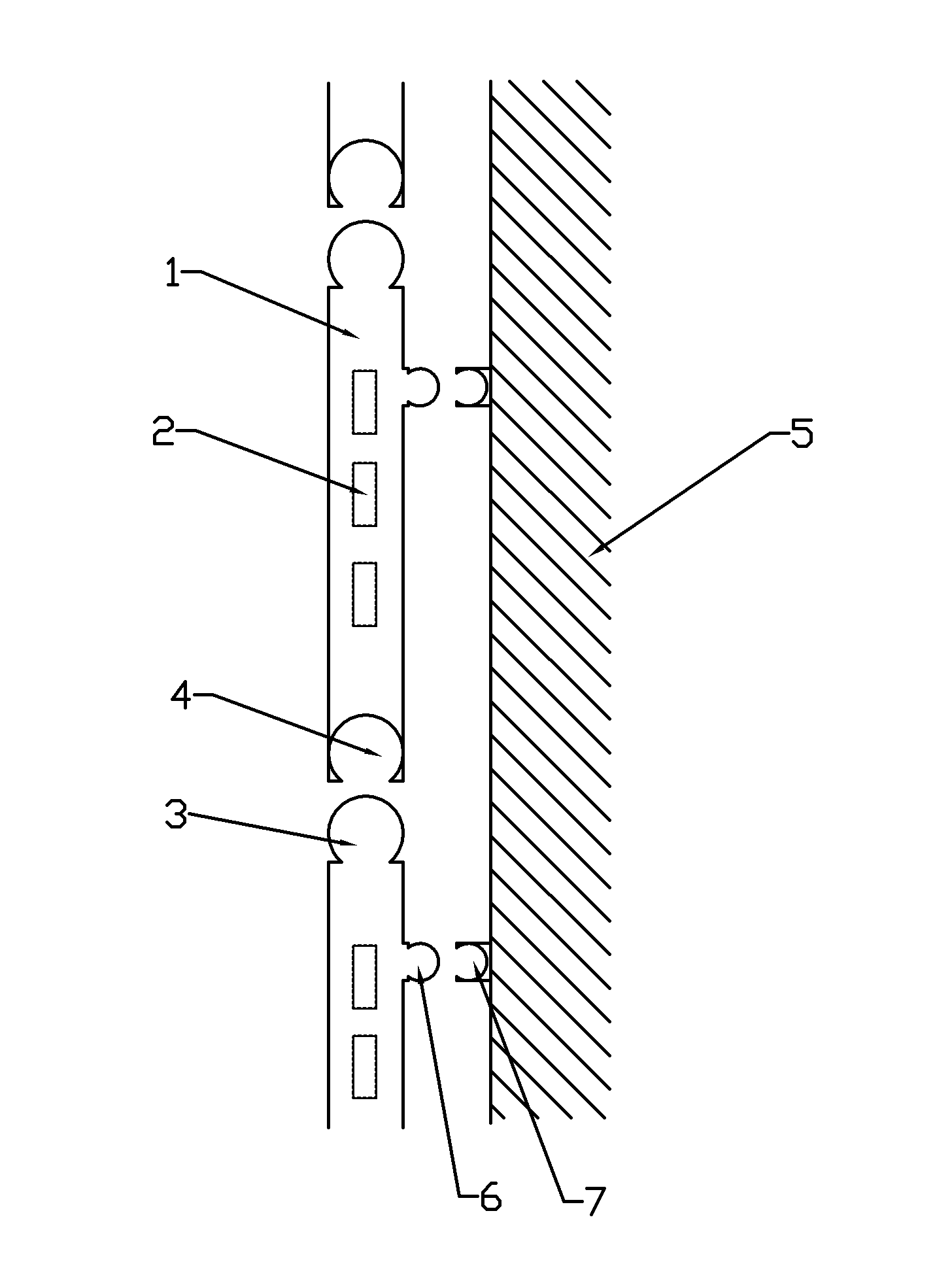

Image

Examples

Embodiment 1

[0017] Formula (percentage by weight): PVC 50%, red mud 44.5%, flow agent (liquid paraffin) 2%, antioxidant 1010 0.5%, anti-ultraviolet auxiliary agent (UV-28) 0.5%, heat stabilizer (metal soap) 1.5%, flame retardant (PP flame retardant masterbatch) 1%

[0018] Production process: take the above-mentioned raw materials according to the above-mentioned parts by weight, stir them evenly in a high-speed mixer, add them to the extruder (plastic) for mixing and plasticization, and then send them to the die head (die) to make a certain shape, and then send them to Enter the patterned roller to press the pattern, and at the same time tap water to cool and shape; after solidification, enter the mobile mold, and finally demould, automatic cutting, and inspection to obtain the finished product.

Embodiment 2

[0020] Recipe: (percentage by weight): PVC 30%, red mud 60%, flow agent (liquid paraffin) 3%, antioxidant 1010 0.2%, anti-ultraviolet auxiliary agent (UV-28) 0.2%, heat stabilizer (metal soap ) 2%, flame retardant (PP flame retardant masterbatch) 4.6%

[0021] Production technology is with embodiment 1.

Embodiment 3

[0023] Formula: (percentage by weight): PVC 64%, red mud 30%, flow agent (DOP) 4%, antioxidant 1076 0.1%, anti-ultraviolet auxiliary agent (UV-28) 0.1%, thermal stabilizer (February silicon dibutyltin ester) 0.5%, flame retardant (ABS flame retardant masterbatch) 1.3%

[0024] Production technology is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com