Angular photochromic material and its preparing method

A photochromic and photoinitiator technology, which is applied in the field of photochromic materials and their preparation, can solve the problems of unevenness and weak color rendering effect, and achieve the effects of wide application, durable color and easy color adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

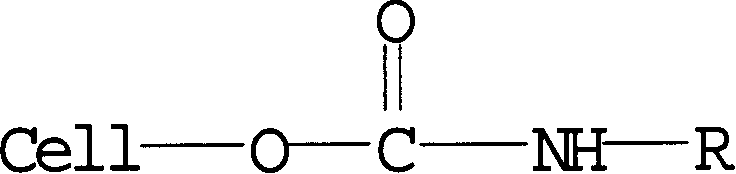

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 10g of cellulose (obtained by hydrolysis of cellulose acetate) in 210ml of pyridine, raise the temperature to reflux, add 50ml of phenylisocyanate, reflux for 48hrs, distill off most of the pyridine under reduced pressure, add 0.8l of methanol, precipitate the solid, filter , Dissolve the filter cake in 600ml of acetone, then add 0.8L of methanol to precipitate the product, filter, wash, and dry in vacuo. 20 g of product was obtained. It was confirmed by IR that the hydroxyl groups in the cellulose microcrystals had basically been completely esterified.

[0029] Dissolve 3.0g of the above-mentioned cellulose derivatives, 5.5g of trimethylolpropane trimethacrylate and 60mg of 2,2-methyl-2-phenylacetophenone in 100ml of acetone, stir vigorously for 2hr, and vacuum off Acetone, the residue is in the form of jelly. Apply this jelly on PET polyester film with a thickness of about 30 μm, place it in a 1.0T magnetic field for 1.0 min, and then cure it with ultraviole...

Embodiment 2~5

[0031] Dissolve 6.0g of the above-mentioned cellulose derivative, 11.0g of trimethylolpropane trimethacrylate and 120mg of 2,2-methyl-2-phenylacetophenone in 200ml of acetone, stir vigorously for 2hr, and remove the Acetone, apply an equal portion of the mixture on the PET film with a thickness of about 30 μm, place it in a magnetic field of different strength for 1.0min, and cure it under the same ultraviolet lamp to obtain a film that selectively reflects light of different wavelengths, as shown in the following table:

[0032] Magnetic Field Strength Film Color (90° Viewing Angle) Reflection Spectrum Absorption Peak (90° Viewing View)

Embodiment 2

[0033] Example 2 1.0T red 652nm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com