Brown coloring method for high borosilicate glass

A high borosilicate glass, brown technology, applied in glass surface treatment, ion diffusion in the field of high borosilicate glass surface coloring, can solve the problems of cumbersome process, difficult control, high production cost, etc., to achieve simple preparation process, smooth surface, The effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

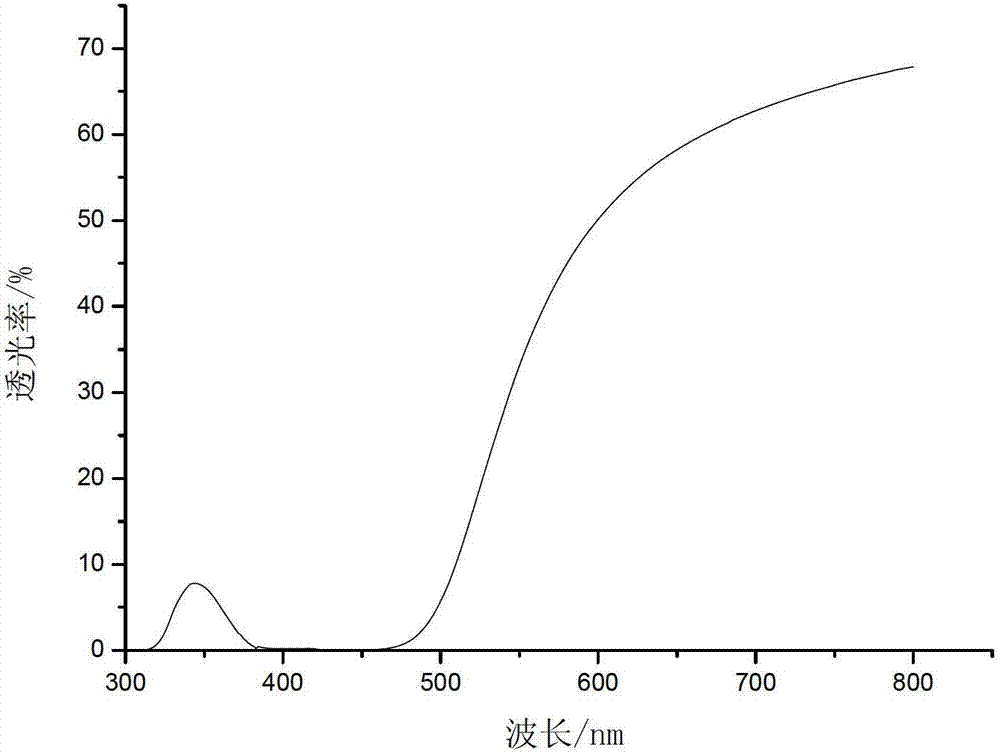

Embodiment 1

[0039] (1) Preparation of colorant paste:

[0040]① Weigh raw materials according to the following components and parts by mass:

[0041] Dextrin powder

7

NaOH

4

AgNO 3

10

CuSO 4

42

FeSO 4

8

toner

13

Zinc powder

3

Glycerin

4

water

12

[0042] ② Preparation of coloring paste

[0043] First, dissolve NaOH in deionized water to prepare NaOH solution, use NaOH solution to reconcile the dextrin powder into a paste (no agglomeration and air bubbles are allowed); then add analytically pure AgNO 3 , CuSO 4 , FeSO 4 , carbon powder and zinc powder, stir evenly, add glycerin after cooling and continue stirring to obtain a mixed slurry.

[0044] (2) Pour the mixed slurry obtained in step ② into a ball mill tank and mill for 3 hours to prepare a coloring material paste whose particle size is required to pass through a 200-mesh sieve.

[0045] (3) Apply ...

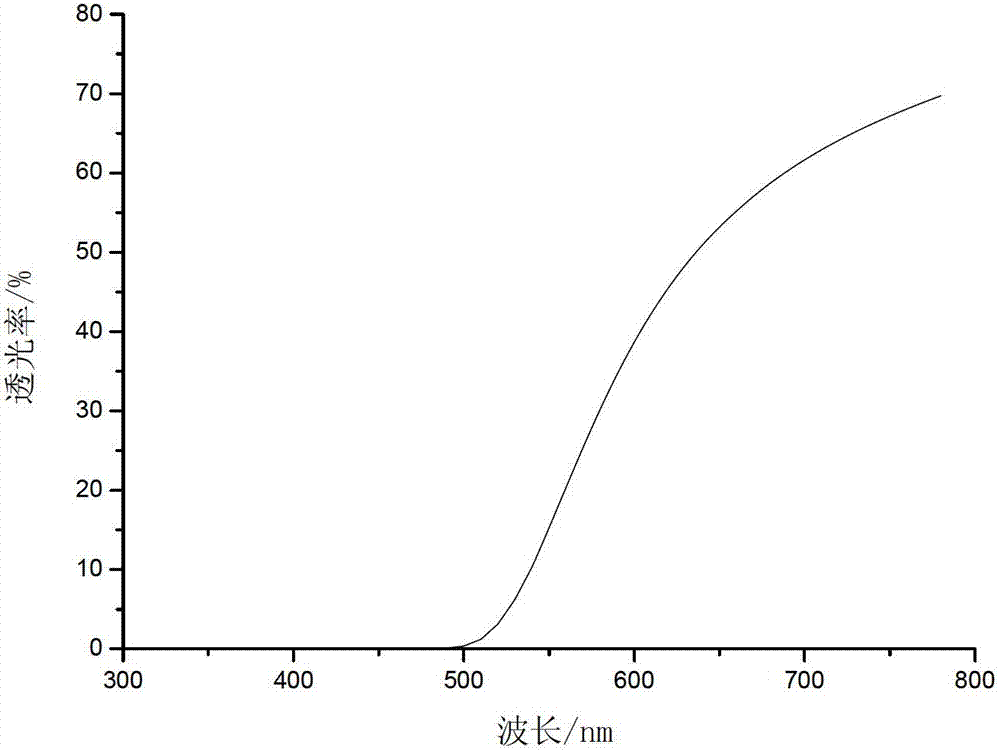

Embodiment 2

[0049] (1) Preparation of colorant paste:

[0050] ① Weigh raw materials according to the following components and parts by mass:

[0051] Dextrin powder

10

NaOH

7

AgNO 3

9

CuSO 4

45

FeSO 4

7

toner

5

Zinc powder

4

Glycerin

4

water

15

[0052] ② Preparation of coloring paste

[0053] First, dissolve NaOH in deionized water to prepare NaOH solution, use NaOH solution to reconcile the dextrin powder into a paste (no agglomeration and air bubbles are allowed); then add analytically pure AgNO 3 , CuSO 4 , FeSO 4 , carbon powder and zinc powder, stir evenly, add glycerin after cooling and continue stirring to obtain a mixed slurry.

[0054] (2) Pour the mixed slurry obtained in step ② into a ball mill tank and mill for 4 hours to prepare a coloring material paste, and the particle size is required to pass through a 300-mesh sieve.

[0055] (3) Use...

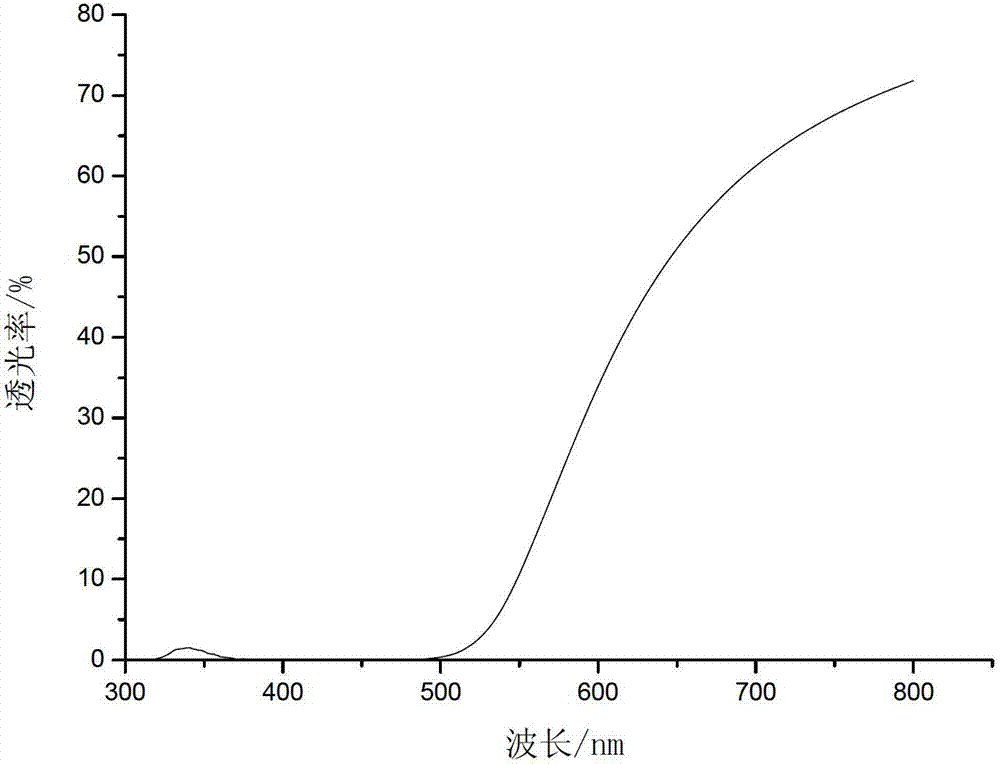

Embodiment 3

[0059] (1) Preparation of colorant paste:

[0060] ① Weigh raw materials according to the following components and parts by mass:

[0061] Dextrin powder

4

NaOH

7

AgNO 3

11

CuSO 4

58

FeSO 4

12

toner

10

Zinc powder

5

Glycerin

3

water

9

[0062] ② Preparation of coloring paste

[0063] First, dissolve NaOH in deionized water to prepare NaOH solution, use NaOH solution to reconcile the dextrin powder into a paste (no agglomeration and air bubbles are allowed); then add analytically pure AgNO 3 , CuSO 4 , FeSO 4 , carbon powder and zinc powder, stir evenly, add glycerin after cooling and continue stirring to obtain a mixed slurry.

[0064] (2) Pour the mixed slurry obtained in step ② into a ball mill tank and mill for 3 hours to prepare a coloring material paste whose particle size is required to pass through a 250-mesh sieve.

[0065] (3) Apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com