Die casting head heat-preservation device for gravity casting and pouring

A heat preservation device and gravity casting technology, which is applied in the field of pouring equipment, can solve the problems of casting defects such as falling sand defects, large consumption of water, electricity and natural gas, and sand core risers that cannot be reused, so as to achieve good heat preservation and shrinkage effects and reduce heat Loss, reduce the effect of cold iron effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

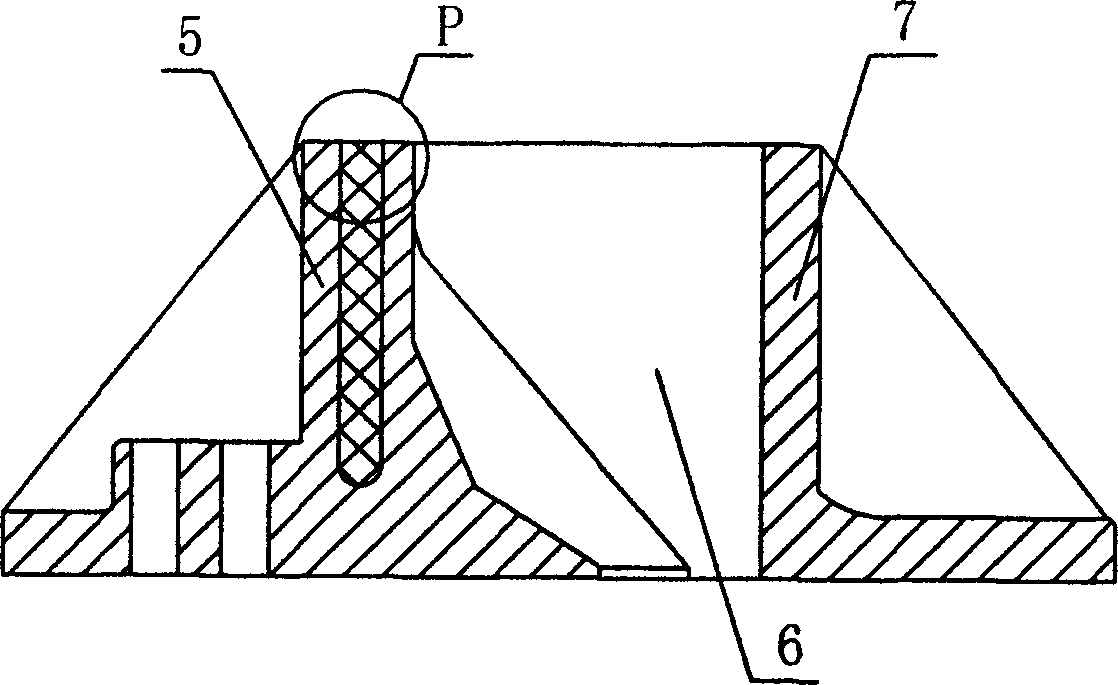

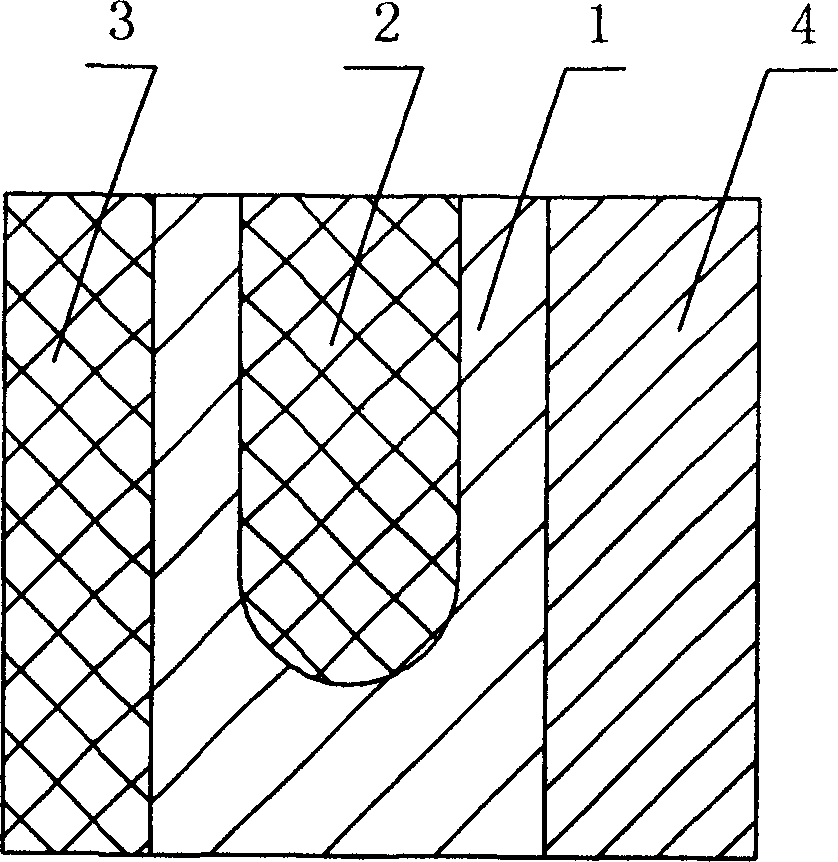

[0014] see figure 1 and figure 2 . The material of this die riser 7 is cast iron 1. A number of blind holes extending from top to bottom are arranged on the mouth wall 5 of the riser, and the blind holes are filled with thermal insulation material 2, the inner wall of the mouth of the riser is coated with thermal insulation paint 3, and the outer wall is covered with thermal insulation material 4 for storage. The heat of the die riser mold reduces the cold iron effect of the die riser.

[0015] When it is necessary to pour metal castings, the exhaust side mold and the pouring mold are fixed. During the pouring process, the pouring metal liquid enters the cavity of the pouring mold through the cavity 6 of the die riser 7 . Due to the thermal insulation material in the blind hole in the thermal insulation device of the present invention, and the thermal insulation coating and the thermal insulation material structure of the inner and outer walls of the mouth of the riser, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com