Outer wall autoclaved aerated concrete self heat insulation system same material thermal bridge treatment construction method

A technology of autoclaved gas filling and construction method, which is applied to the processing of building materials, heat preservation, climate change adaptation, etc. It can solve the problems of poor appearance quality and high heat consumption, and achieve excellent heat insulation and maintain appearance quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

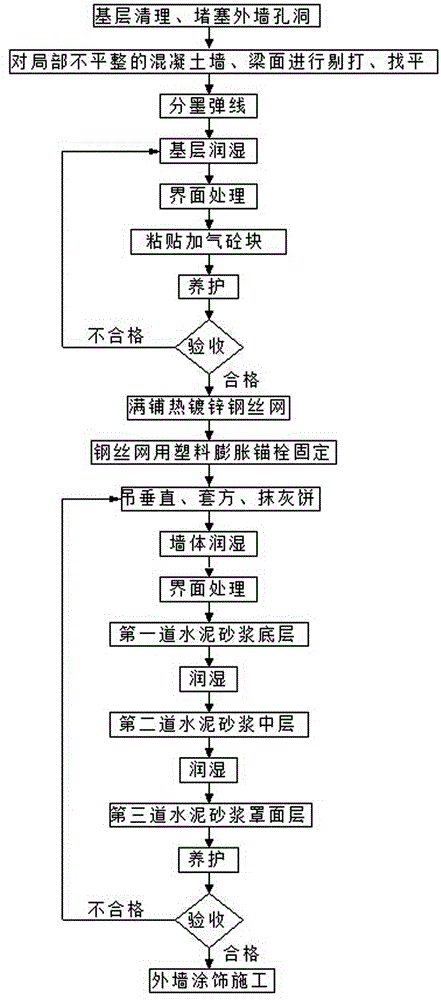

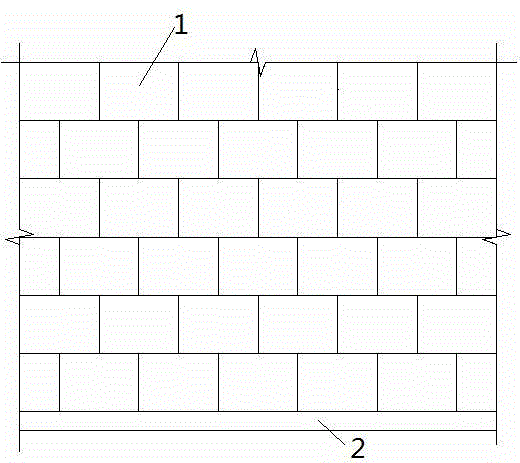

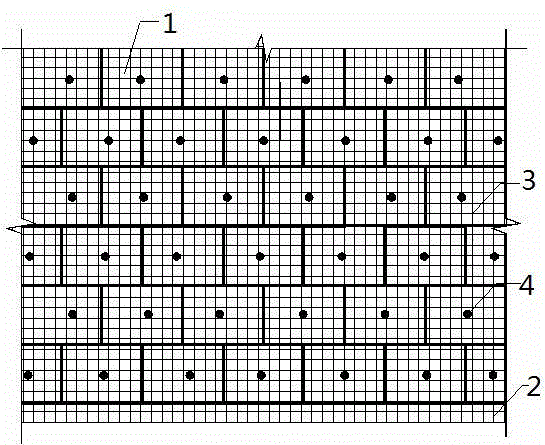

[0039] Such as figure 1 As shown, the construction method steps of the present embodiment are as follows:

[0040] 1. Grassroots cleanup

[0041] Clean up the floating sand and debris on the surface of the concrete base at the thermal bridge, use a foaming agent to block the wall-through screw holes for the formwork, and use fine stone concrete of the same grade as the wall concrete to pour the reserved openings for the outer frame. Beat the partially uneven concrete wall or beam concrete, and use 1:1 cement fish rice stone to level the wall depression.

[0042] Two, elastic thread

[0043] According to the design requirements, the specification and quantity of autoclaved aerated concrete thin blocks, typesetting is carried out, and horizontal and vertical lines are laid out in sections. For the pasting of thin aerated concrete blocks o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com