Comprehensive parameter testing system of suspension type material transmitting device

A comprehensive parameter and material transmission technology, which is applied in the field of comprehensive parameter test system of suspended material transmission device, can solve the problems of power application influence, unstable operation of transmission system, power waste, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present application more obvious and understandable, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

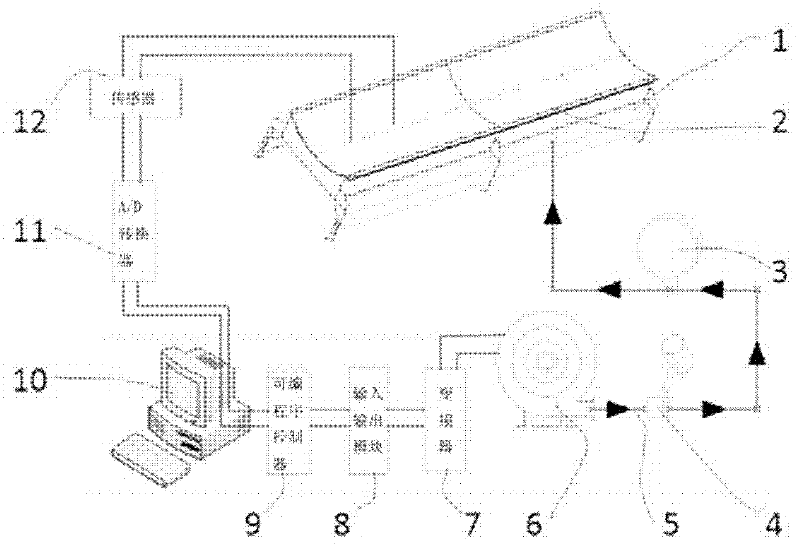

[0031] refer to figure 1 , shows a structural diagram of a comprehensive parameter testing system for a suspended material conveying device of the present application.

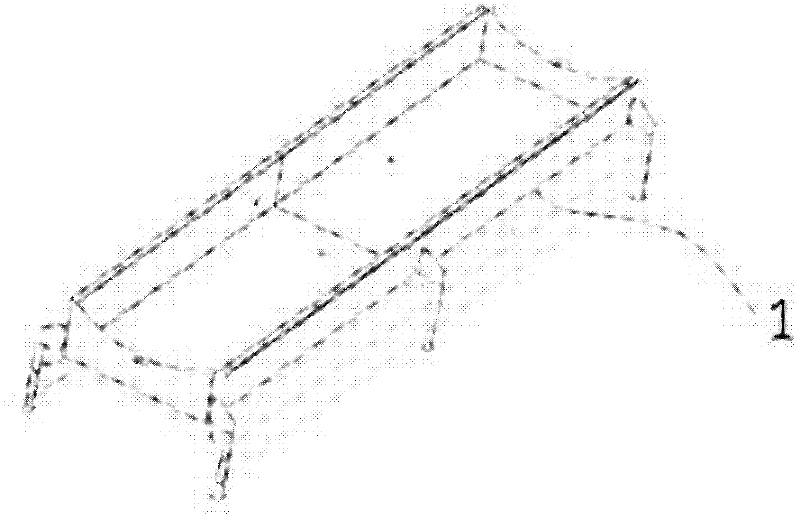

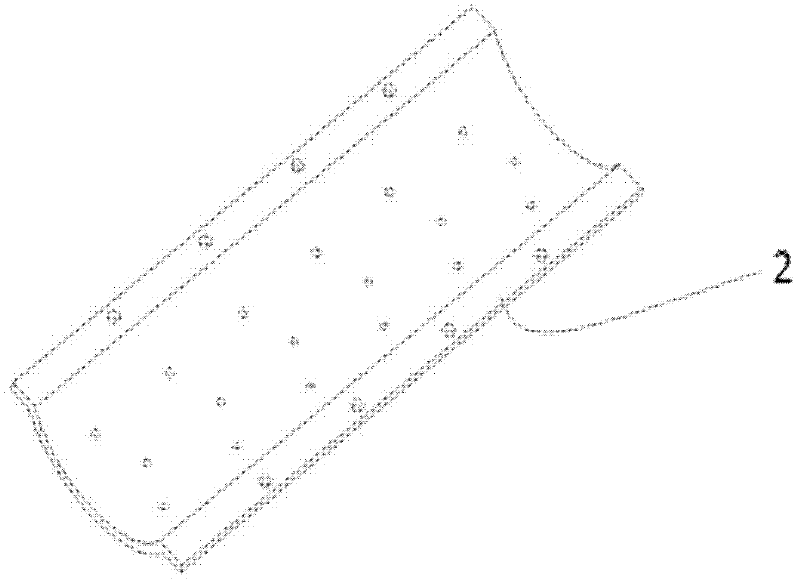

[0032] The system includes: a suspension conveyor test bench (1), a plurality of disk slots (2), a fan (6), a frequency converter (7), a PC (10), and a sensor (12), among which,

[0033] The disk groove (2) is installed on the suspension conveyor test bench (1), and one disk groove (2) is installed for each test, and the disk groove (2) has air holes;

[0034] A transmission belt is placed on the disk groove (2), the sensor (12) is installed on the transmission belt, the sensor (12) is connected with the PC (10), and the signal is trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com