Method and system of grain detecting

A detection method and grain technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem that the grain cannot be in contact with the probe accurately, so as to solve the problem of different sizes of needle marks, ensure contact, prevent The effect of very small needle marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

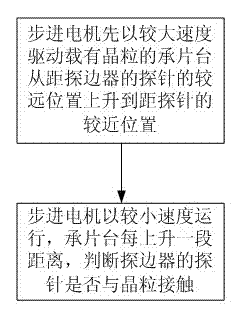

[0031] Such as figure 1 Shown, the specific embodiment of a kind of grain detecting method, comprises the following steps:

[0032] A. The stepper motor first drives the wafer stage loaded with crystal grains at a higher speed to rise from a position farther away from the probe of the edge detector to a position closer to the probe;

[0033] B. The stepping motor runs at a small speed, and every time the wafer table rises for a certain distance, it is judged whether the probe of the edge detector is in contact with the die.

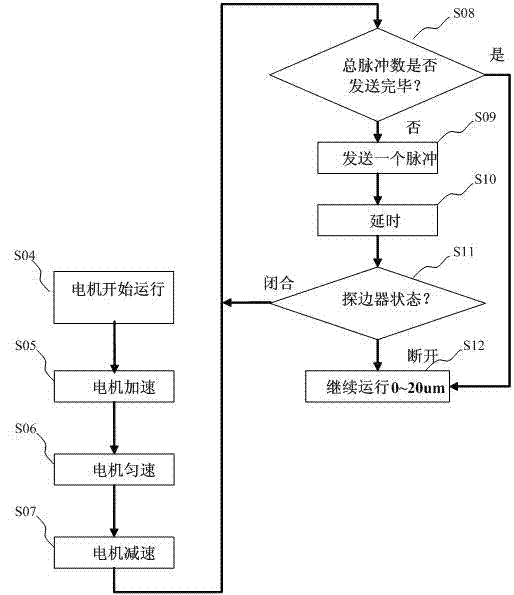

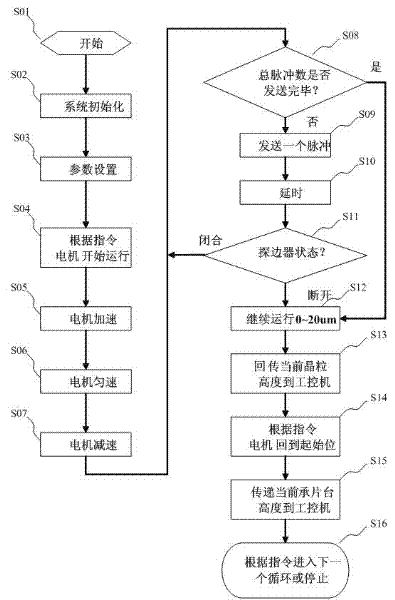

[0034] Such as figure 2 As shown, a more specific embodiment of a grain detection method:

[0035] S04. The stepper motor starts to run, driving the wafer carrier loaded with crystal grains to rise;

[0036] S05-S07. After the stepper motor has gone through three stages of acceleration, constant speed and dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com