Breakdown maintenance and fault analysis method for complicated equipment

A fault analysis method and technology of fault analysis, applied in the direction of neural learning methods, instruments, biological neural network models, etc., can solve problems such as greater influence on the accuracy of fault trees, fault knowledge expression, and complex fault relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

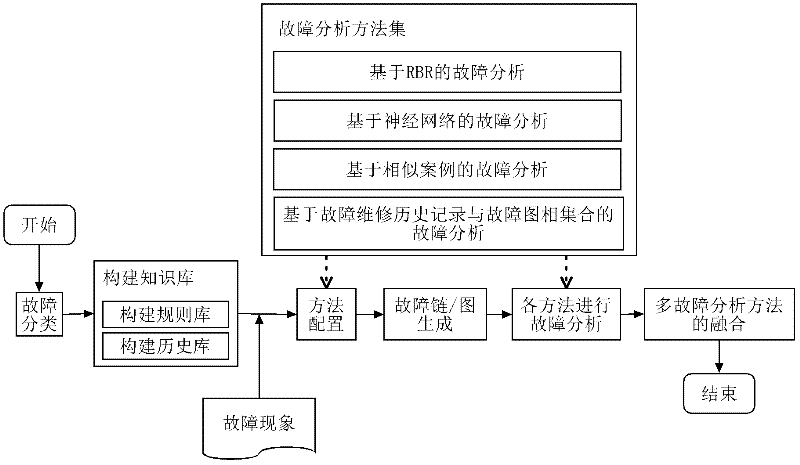

[0038] as attached Figure 1 Shown, the present invention comprises the following steps:

[0039] Step 1, fault classification.

[0040] According to the different fault objects, the faults are divided into: (a) structural faults, which have obvious fault objects, and must be eradicated by self-replacement or maintenance; (b) functional faults, which can be eliminated by repairing or adjusting other objects. Troubleshooting; (c) external faults, including process, environment, human operation and other fault states that do not meet the equipment requirements.

[0041] According to the degree of visibility, faults are divided into: (a) symptomatic faults, also known as fault symptoms or fault phenomena, that is, faults that can be detected by facial features or conventional measuring instruments, which are the appearance of faults deteriorating to a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com