Light-emitting diode (LED) package and backlight module with LED package

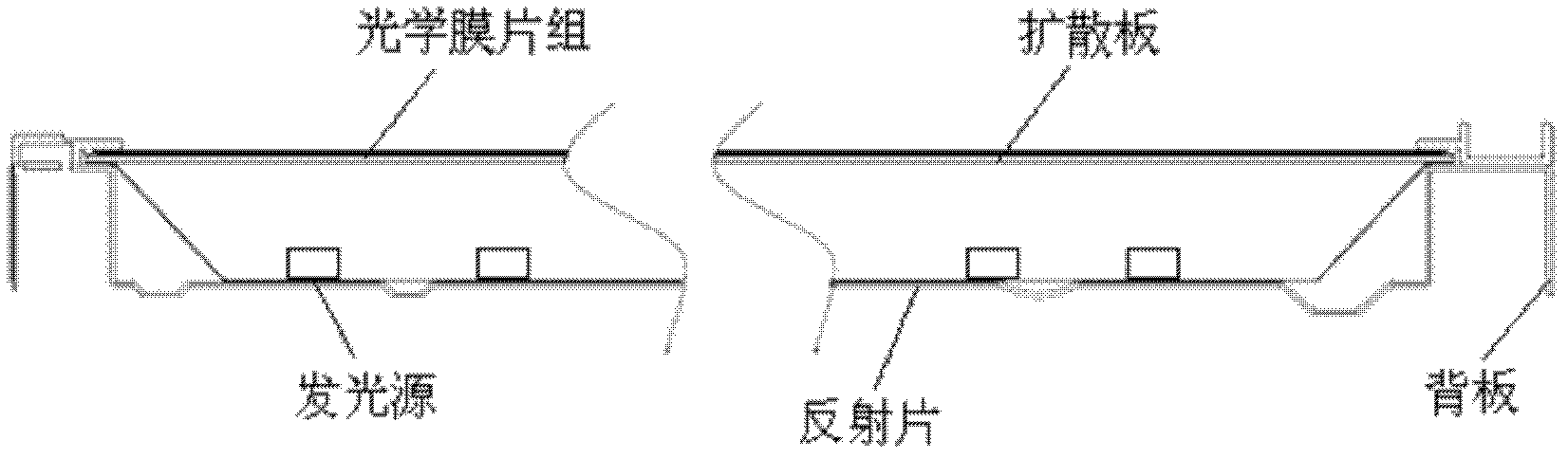

A technology of LED encapsulation and backlight module, applied in electric light source, lighting device, fixed lighting device, etc., can solve the problems of increasing the cost of backlight module and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

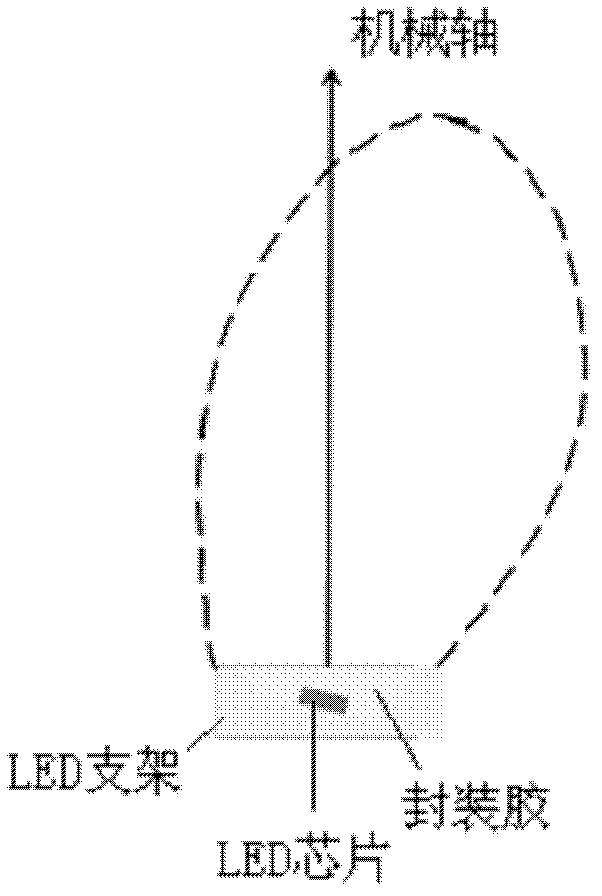

Embodiment 1

[0027] Such as Figure 4 As shown, the LED support includes a lower surface, two side surfaces, and two upper surfaces. The LED chip is arranged above the lower surface of the LED support. The encapsulation glue covers the LED support and the LED chip, and also includes a phosphor located in the encapsulation glue. (Not shown in the figure). In this embodiment, the slopes of the two side surfaces of the LED bracket are different, and the slope of the right side surface is smaller, which reflects the light emitted by the LED chip to the side surface to a large angle, and emits the LED package. The left side surface With a larger slope, the light emitted by the LED chip hitting the side surface is not easily refracted out of the LED package, so a larger ratio of light will be reflected off the LED package from the right side surface. The material of the LED bracket is a material with a reflective function (reflective material), which can be a plastic material or a ceramic materia...

Embodiment 2

[0029] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the slopes of the two side surfaces of the LED bracket are the same, and the lower surface of the LED bracket is an inclined plane. Due to the influence of the inclined plane, the light emitting behavior of the entire LED package is asymmetric.

Embodiment 3

[0031] Such as Image 6 As shown, the difference between this embodiment and embodiment 2 is that the lower surface of the LED bracket is a horizontal plane, and it also includes a secondary lens arranged above the upper surface of the LED bracket, and the secondary lens includes two asymmetric arc surfaces, The concave arc surface on the left transmits less light, and the convex arc surface on the right transmits more light, which makes the light-emitting behavior of the entire LED package asymmetric.

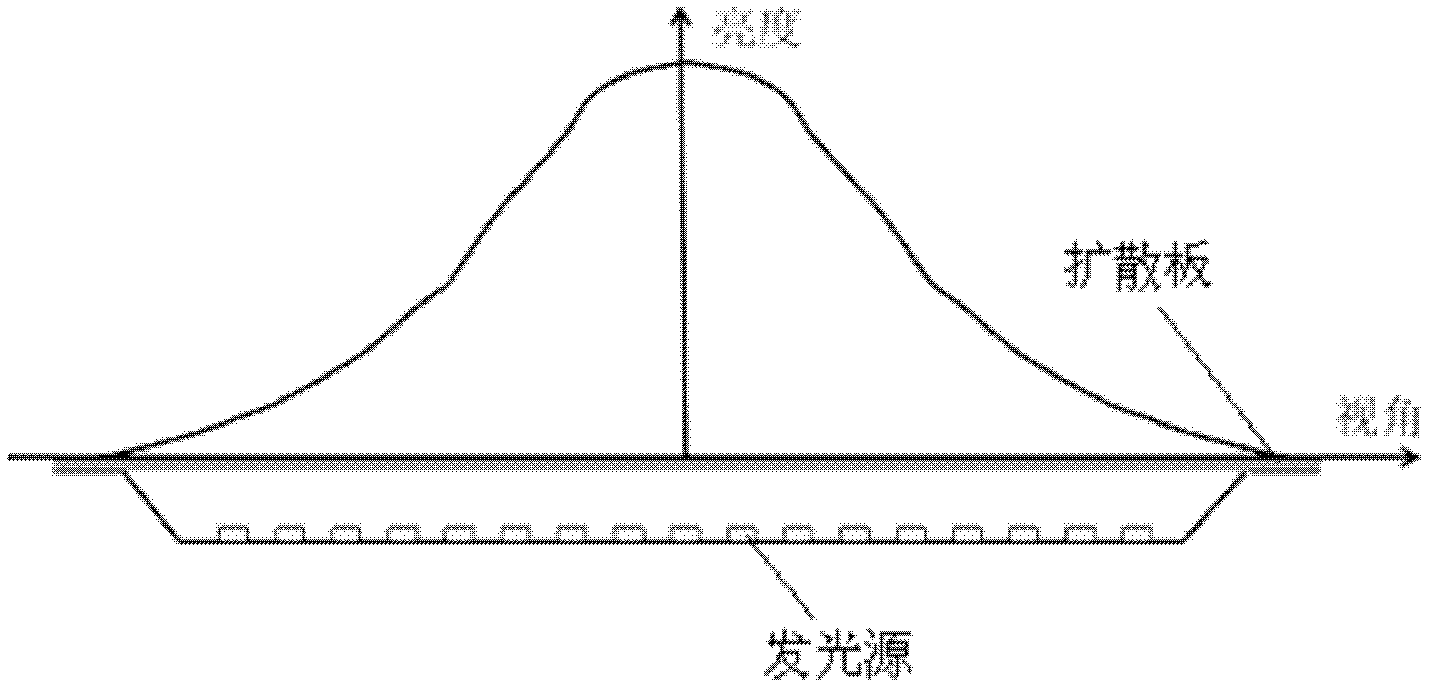

[0032] As shown in Fig. 3, Fig. 3(b) shows the light-emitting behavior of a traditional LED package. It can be seen that the light-emitting behavior is symmetrical with respect to the mechanical axis, that is, there are as many light rays on the left and right sides of the mechanical axis. Figures 3(a) and 3(c) show the light-emitting behavior of the LED package of the present invention. It can be seen that these two light-emitting behaviors are asymmetric with respect to the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com