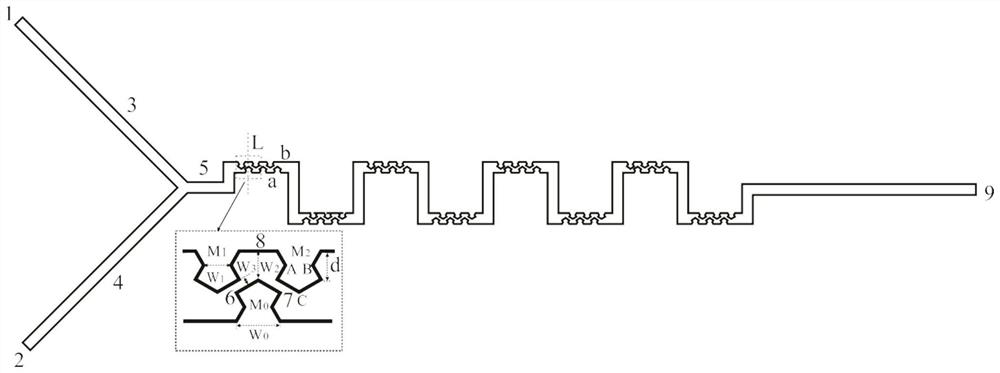

A Passive Convergent-Divergent Micromixer for Low Diffusion Coefficient Fluids

A micro-mixer and fluid mixing technology, applied in the field of micro-total analysis system, can solve the problems of high energy consumption of active mixer and high complexity of micro-fluidic system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0049] The present invention proposes a passive convergent-divergent micro-mixer for fluids with low diffusion coefficient. The mixer is made of polydimethylsiloxane (PDMS). The channel structure pattern is transferred to a single crystal silicon wafer to obtain a positive mold; then the PDMS stock solution and the curing agent are mixed evenly at a ratio of 10:1, and the air bubbles in the PDMS mixed solution are discharged using a vacuum drying oven, and then coated on the mold, and then vacuumed again Remove the air bubbles on the mold, and then heat at a constant temperature of 80°C for two hours; finally, peel off the heated and cured PDMS from the single crystal silicon wafer in absolute ethanol, then clean it with deionized water, and dry it with nitrogen gas for later use. Permanently bond the PDMS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com