Upper boom for multifunctional demolition robot working device and processing method thereof

A working device and robot technology, applied in construction, building maintenance, building construction, etc., can solve problems such as uneven stress distribution of side plates, reduced life span of upper boom, and reduced machining accuracy, so as to improve stress distribution, box Effect of increased body thickness, increased strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

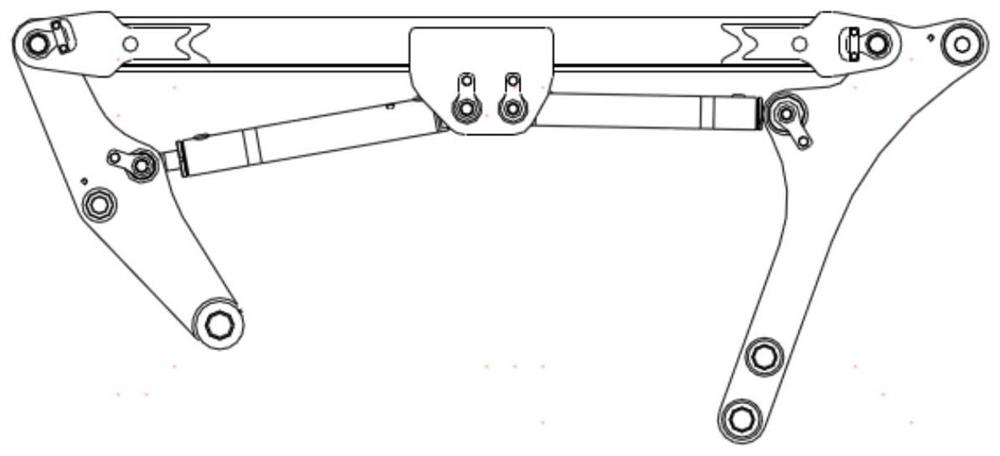

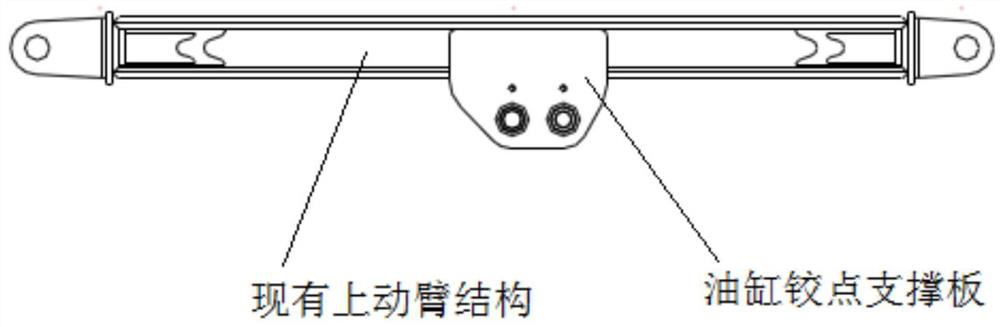

[0035] like figure 1 As shown, it is the installation position of the upper boom of the working device of the multifunctional demolition robot. The upper boom is a component that connects the lower boom and the stick through the hinge shaft, and can rotate along the hinge shaft. Its shape and structure must ensure Certain installation accuracy. When subjected to load external force, it should also have sufficient strength and rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com