Skid shoe guide rail type cable trailer

A cable trailer and rail type technology, applied in cable laying equipment and other directions, can solve the problems of high labor intensity and low safety factor, and achieve the effect of reducing work intensity, low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

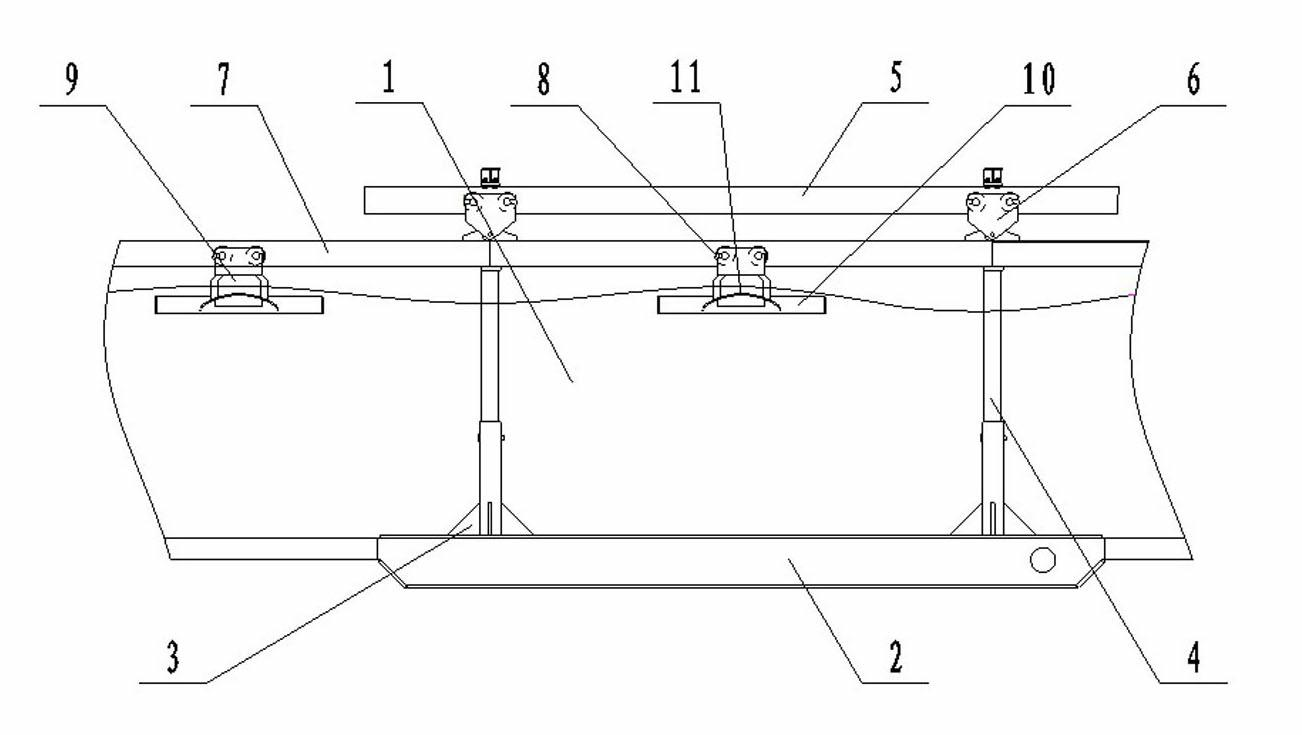

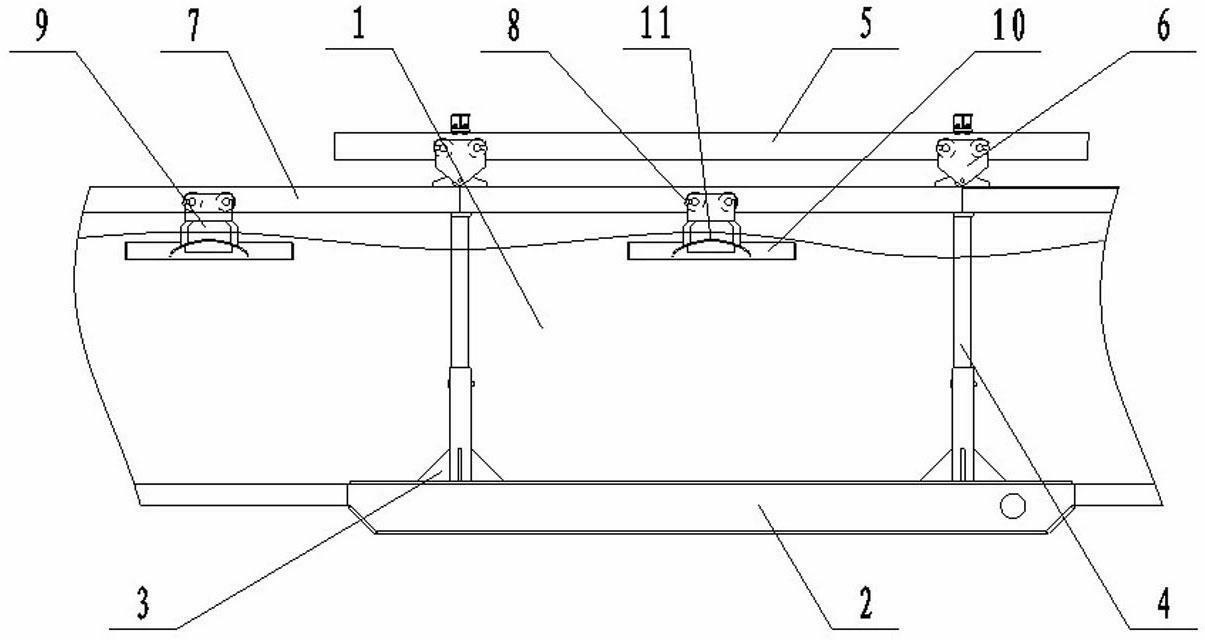

[0008] Sliding shoe rail type cable trailer, including several trailer bodies 1 connected in sequence. The trailer body 1 includes a sliding shoe base 2. Column sockets 3 are fixed on the front and rear sides of the base 2. Single hydraulic upright columns are installed in the column sockets 3. 4. A crossbeam 5 is fixed between the upper ends of the two single hydraulic props 4 on each trailer body 1, and the left and right sides of the crossbeam 5 are hinged with hooks 6, and the hooks 6 are provided with I-shaped steel beams 7, and a The I-shaped steel beam 7 is suspended on all hooks 6, and the I-shaped steel beam 7 is evenly distributed with some pulleys 8 sliding on the left and right sides of the I-shaped steel beam 7. The pulley 8 is arranged on the pulley frame 9, and the lower end of the pulley frame 9 A vertically arranged baffle plate 10 is fixed, and the left and right sides of the baffle plate 10 are all fixed with hanging plates 11 fixed at an acute angle thereto....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com