H-bridge driving circuit

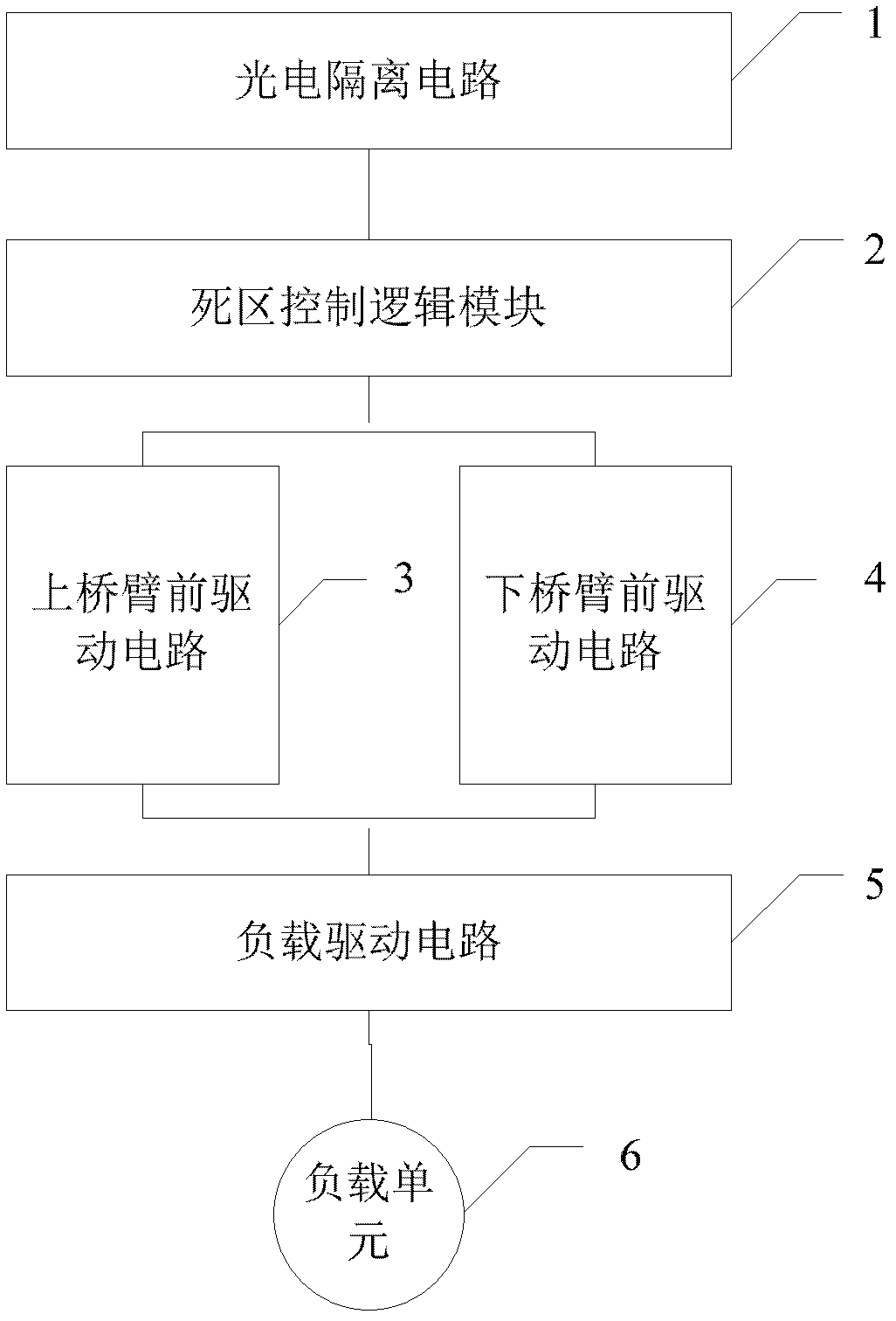

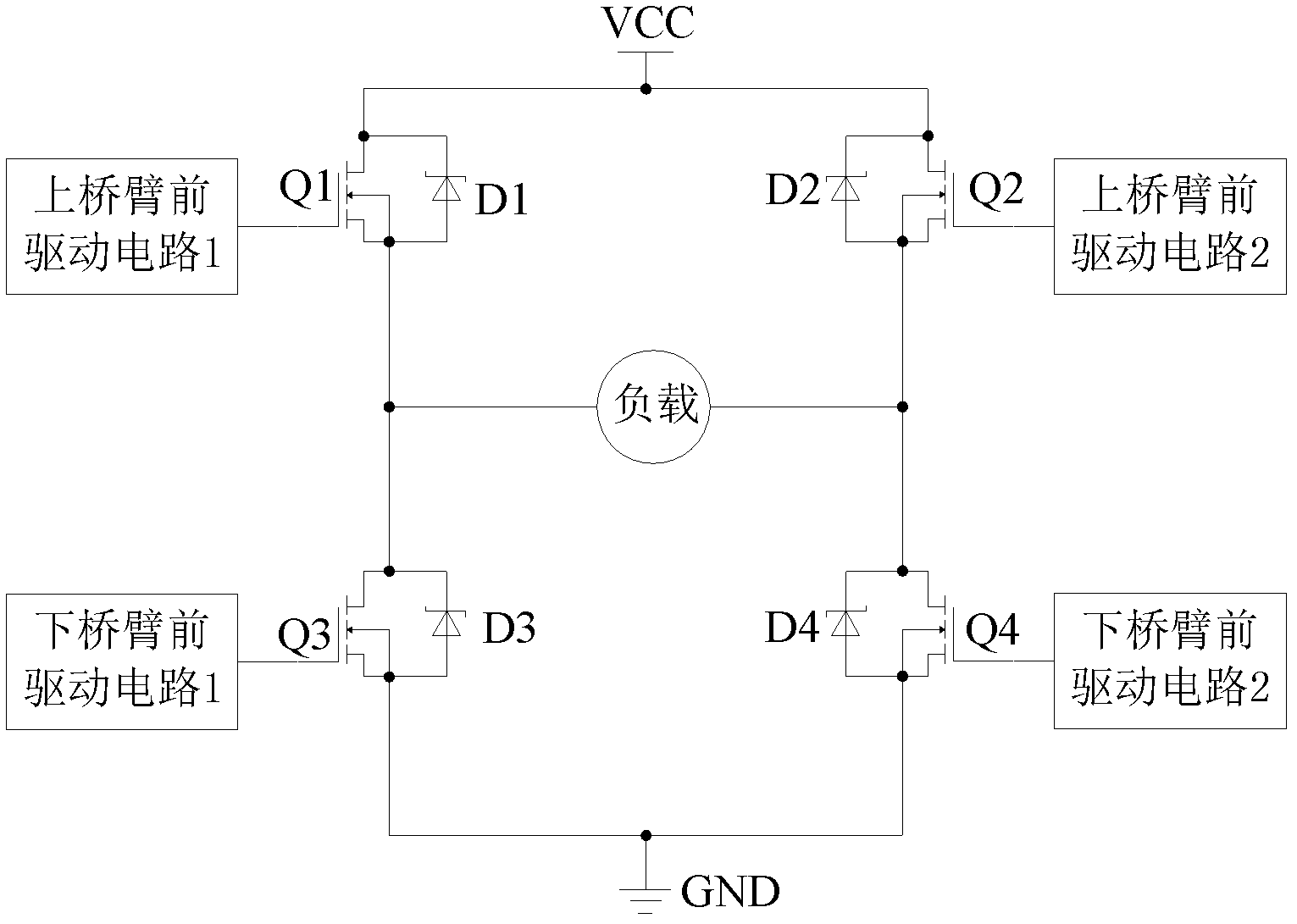

A bridge drive circuit and circuit technology, applied in the field of excitation or armature current control, etc., can solve problems such as hindering the output frequency of the H bridge drive circuit, achieve the effect of accelerating the closing speed and meeting the driving demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

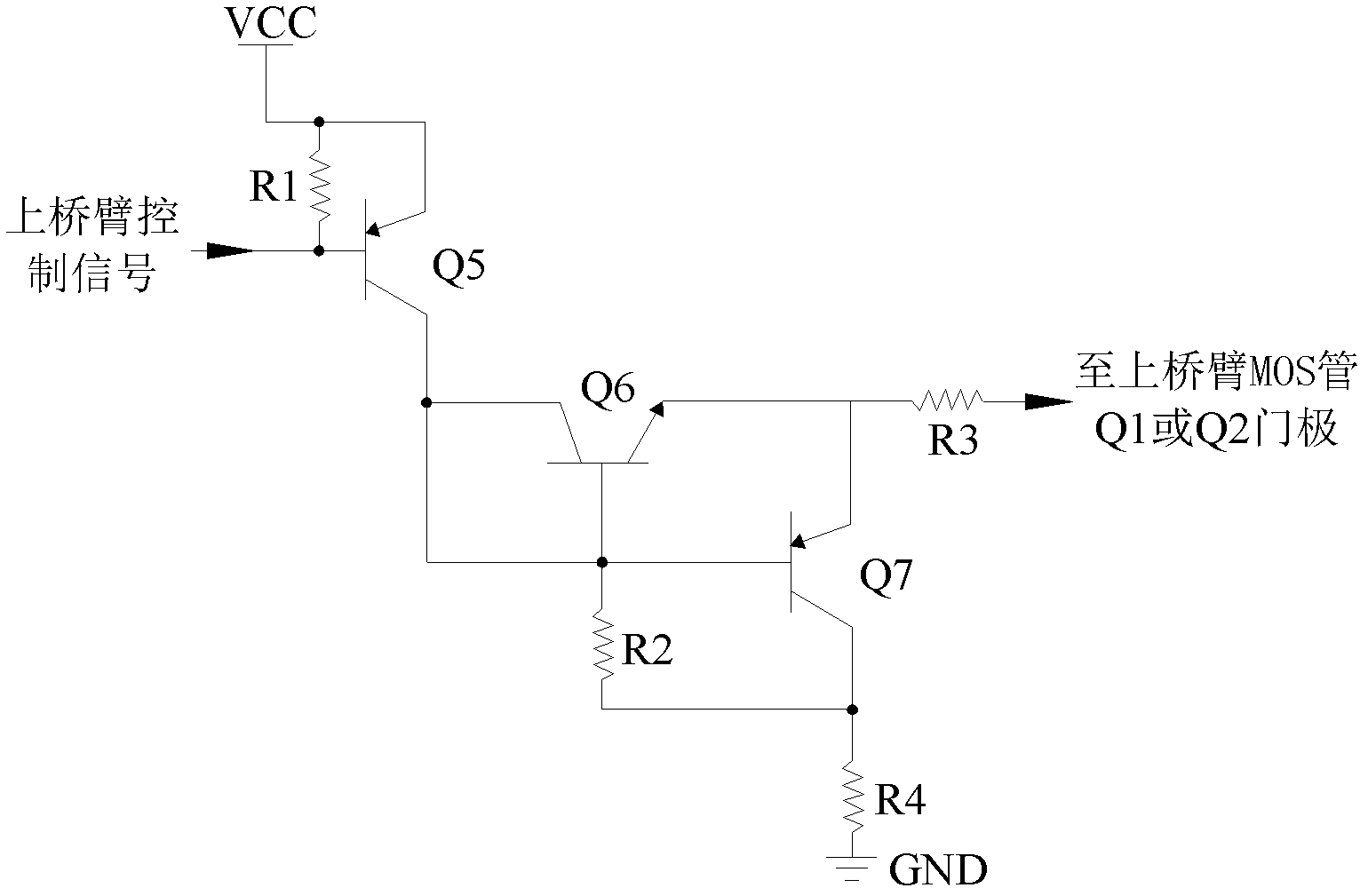

[0059] In the prior art, when the H-bridge drive circuit is turned off, there is a large junction capacitance between the gate and the source of the MOS transistor, that is, when the voltage at both ends of the load unit changes, the load unit exhibits a capacitive effect. The existence of the junction capacitance delays the rise and fall time of the gate drive voltage of the MOS transistor. In this application, a discharge circuit is added at the gate of the MOS tube to form a front drive circuit of the MOS tube, so as to speed up the discharge speed of the MOS tube and increase the closing speed of the MOS tube. Therefore, the capacitive effect of the load unit of the H-bridge driving circuit when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com