Flue gas purification system capable of simultaneously realizing high-efficiency dust removal and mercury removal

A flue gas purification system and mercury removal technology, applied in chemical instruments and methods, lighting and heating equipment, combined devices, etc., can solve the problems of low dust removal efficiency of electrostatic precipitators, reduce usage, improve adsorption effect, reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

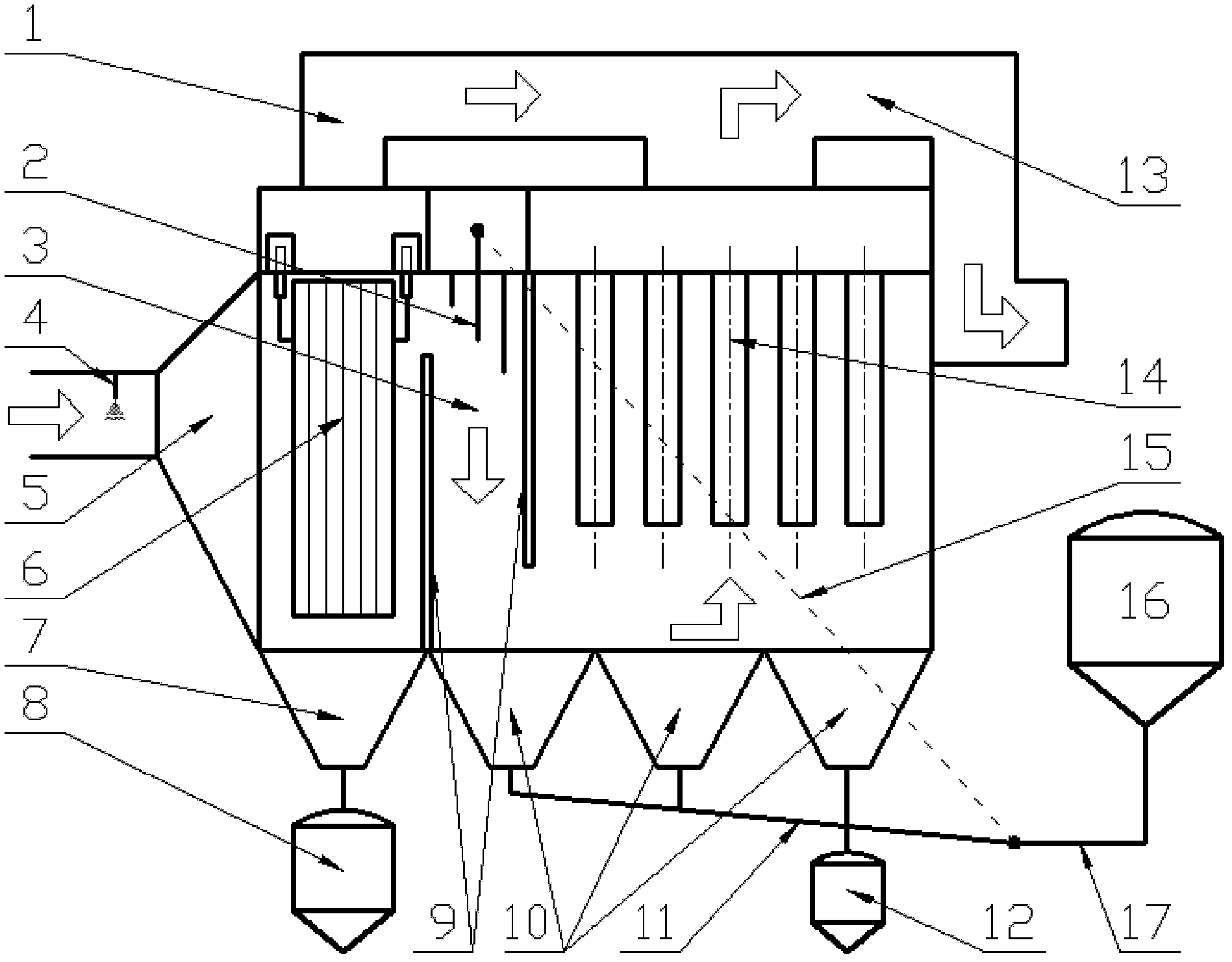

[0033] like figure 1 As shown, a flue gas purification system that can simultaneously achieve high-efficiency dust removal and mercury removal includes an inlet smoke box 5, the inlet smoke box 5 is connected to the electrostatic dust removal area 6, the outlet flue 13 is connected to the bag dust removal area 14, and the electrostatic dust removal area 6 is connected to the cloth bag dust removal area 14. Adsorbent injection areas 3 are arranged between the dust removal areas 14, and a spray grid 2 is arranged on the top of the adsorbent injection areas 3, so as to inject powdery mercury removal adsorbent and / or fine ash into the flue gas.

[0034] There are non-closed baffles 9 between the electrostatic precipitation area 6 and the adsorbent injection area 3, and between the adsorbent injection area 3 and the bag dust removal area 14. Among them, the electrostatic precipitation area 6 and the injection grid of the adsorbent injection area 3 The end where the grid 2 is locate...

Embodiment 2

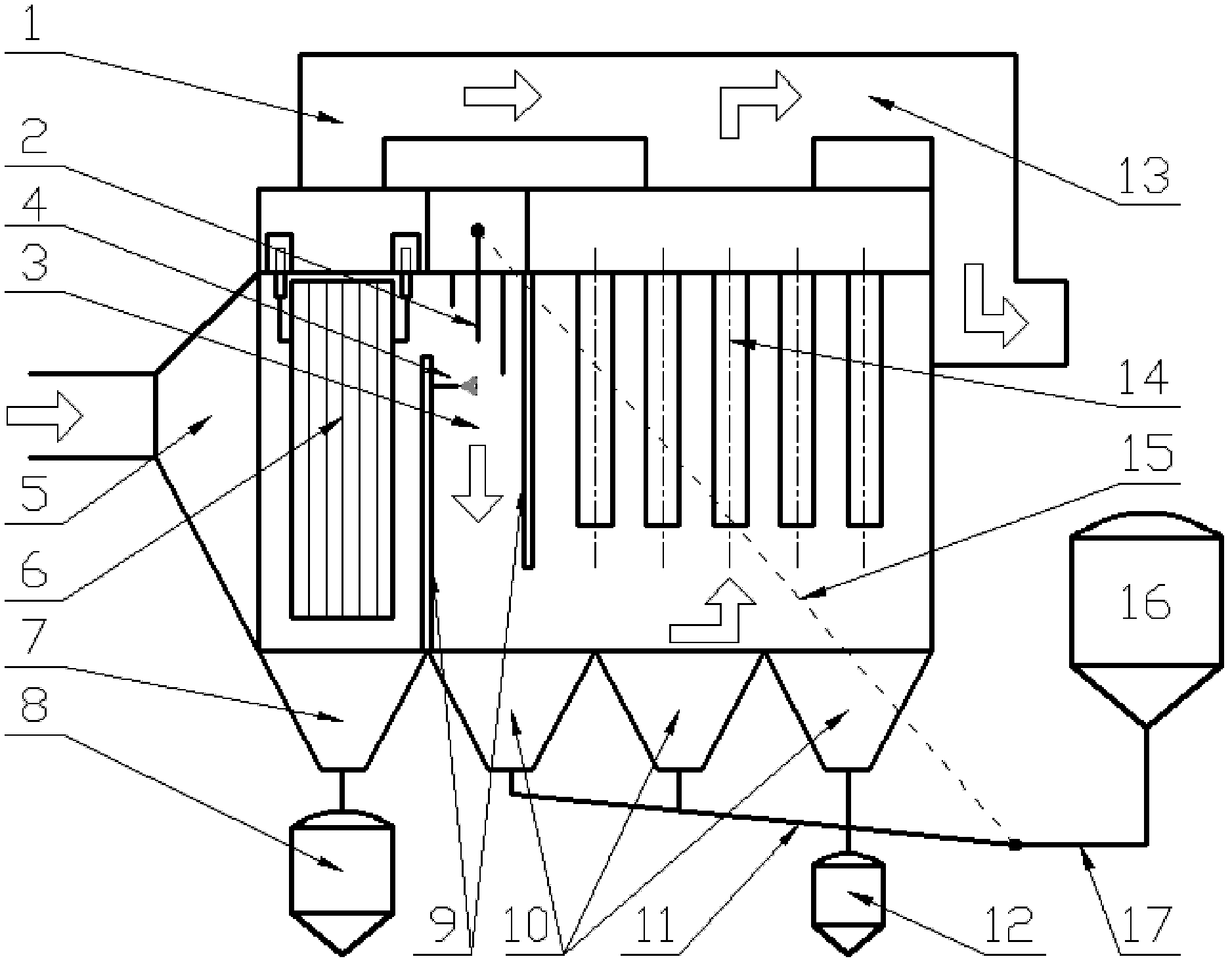

[0042] like figure 2 As shown, the difference from the first embodiment is that slaked lime is used as the adsorbent, which can realize the simultaneous removal of SOx and mercury. Therefore, the system also has a certain desulfurization capacity while realizing high-efficiency dust removal and mercury removal. The spray cooler 4 is arranged in the upper part of the sorbent injection zone 3, not only to prevent the flue gas temperature from being too high, thereby ensuring the service life of the cloth bag and the efficiency of adsorption and removal of mercury; After contacting, the activity of slaked lime for desulfurization and mercury removal can be enhanced.

[0043] When the system of the present invention is in operation, the flue gas first enters the electrostatic precipitator area 6 from the inlet smoke box 5 to remove most of the dust of large particles; then in the adsorbent injection area 3, the adsorbent is sprayed into the flue gas; then The flue gas passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com