Fluidization atomization-liquid film washing combined flue gas purifying device and method

A purification device and flue gas purification technology, applied in the field of flue gas purification, can solve the problems of difficulty in reaching a high level of desulfurization and dust removal efficiency, small momentum transfer, high flow pressure drop, etc., to improve stability and load adaptability, The effect of size reduction such as height, reduction of head and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are examples of the present invention, which are only used for explanation of the application and not for limitation.

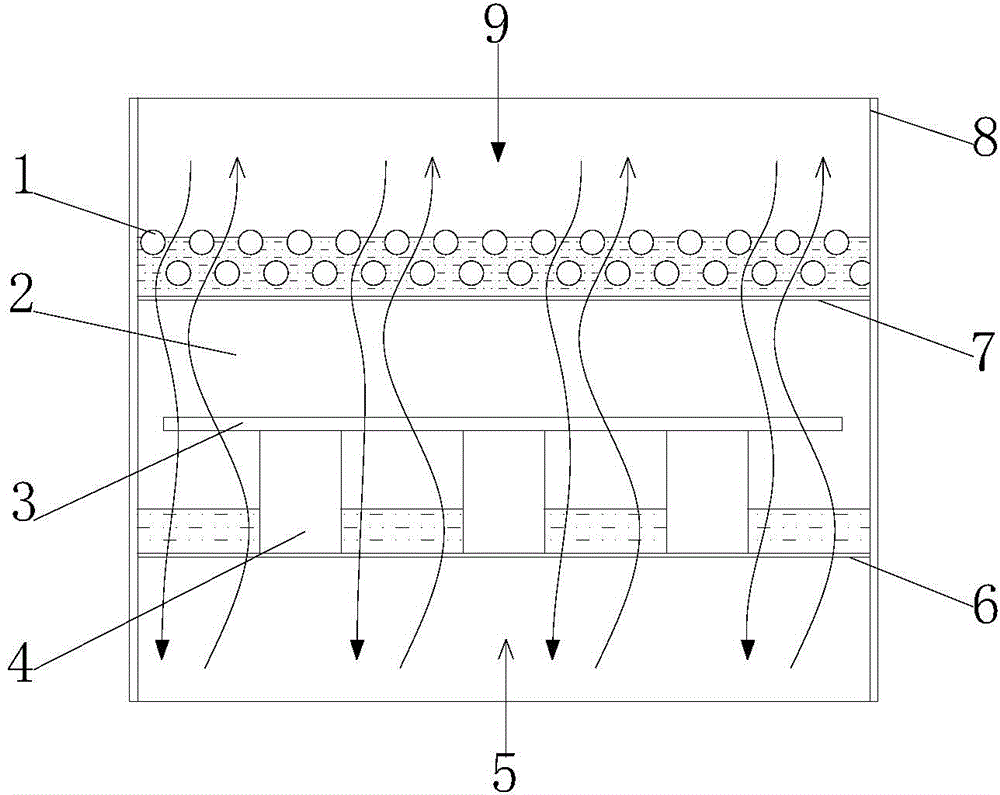

[0046] See figure 1 , A flue gas purification device combining fluidized atomization and liquid film washing. The purification device 8 includes a gas distribution net 6 located in the lower part and a liquid distribution net 7 located in the upper part. The gas distribution net 6 and the liquid distribution net 7 are arranged With meshes, the purification liquid 9 can be separated into fine liquid streams through the liquid distribution net 7 and fall into the fluidized atomization layer, and then pass through the gas distribution net 6 to leave; the flue gas 5 to be purified can evenly enter the flow through the gas distribution net 6 The atomized layer will then pass through the liquid cloth net 7 and the liquid film layer above it and leave.

[0047] The flue gas and the purified liquid adopt countercurrent mass transfer, and the flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com