Long-range conical high-flow-rate pneumatic nozzle

A long-range, high-flow technology, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of small water flow, low vacuum efficiency, small work area, etc., and achieve the expansion of spraying angle, long range and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

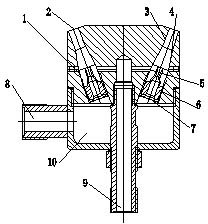

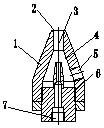

[0017] Each nozzle of the present invention comprises the pneumatic nozzle 7 that is provided with air inlet 6, and the outside of pneumatic nozzle 6 is provided with and cooperates pneumatic nozzle body 1, and the side wall of pneumatic nozzle body 1 is provided with water inlet 5, and the air nozzle body 6 The air outlet is arranged in the tapered section 4; the distance between the air outlet and the water mist outlet 2 is 2.5-3.5 times of the water mist outlet aperture, preferably 3 times.

[0018] The working process of each nozzle of the present invention is: the gas is input by the air inlet 7 of the pneumatic nozzle 6, the gas is ejected at a high speed through the outlet of the pneumatic nozzle 6, and the periphery of the gas jet produces a vacuum effect, that is, a vacuum zone (negative pressure) is formed. The vacuum area is connected with the water inlet chamber, and the water will be automatically inhaled and collided with air to mix and atomize, and then the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com