Tool and method for processing bearing pedestal by using lathe

A lathe processing and bearing seat technology, applied in metal processing equipment, metal processing mechanical parts, supports, etc., can solve the problems of low processing efficiency and cumbersome operation, and achieve the effect of easy operation, flexible lathe operation, and flexible production load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

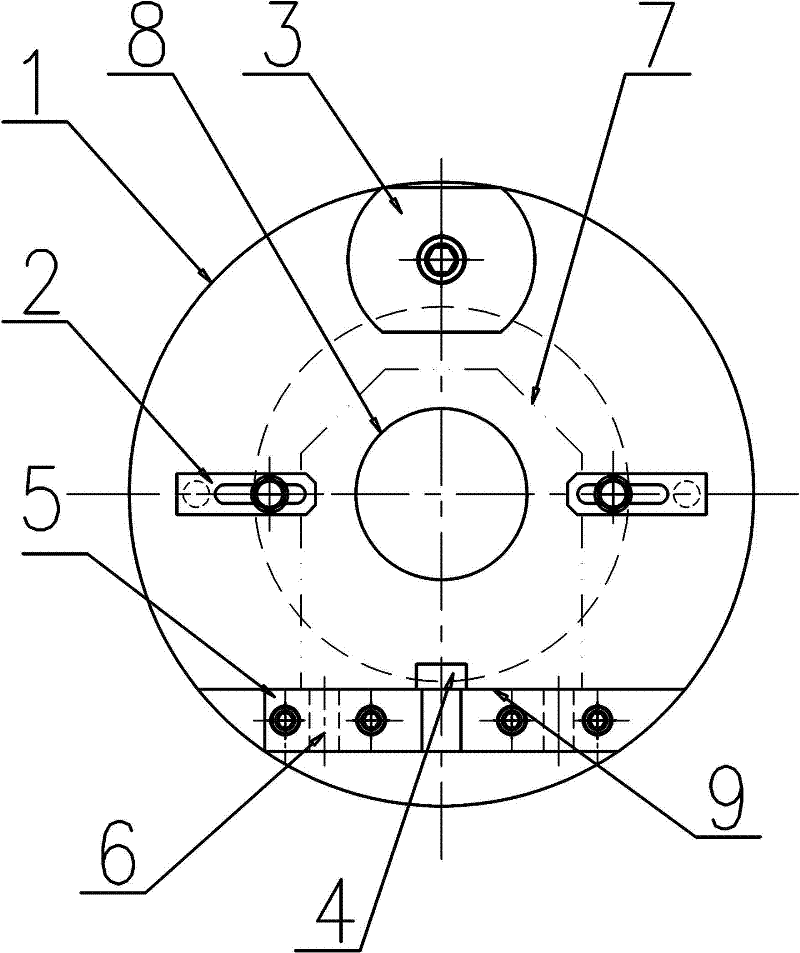

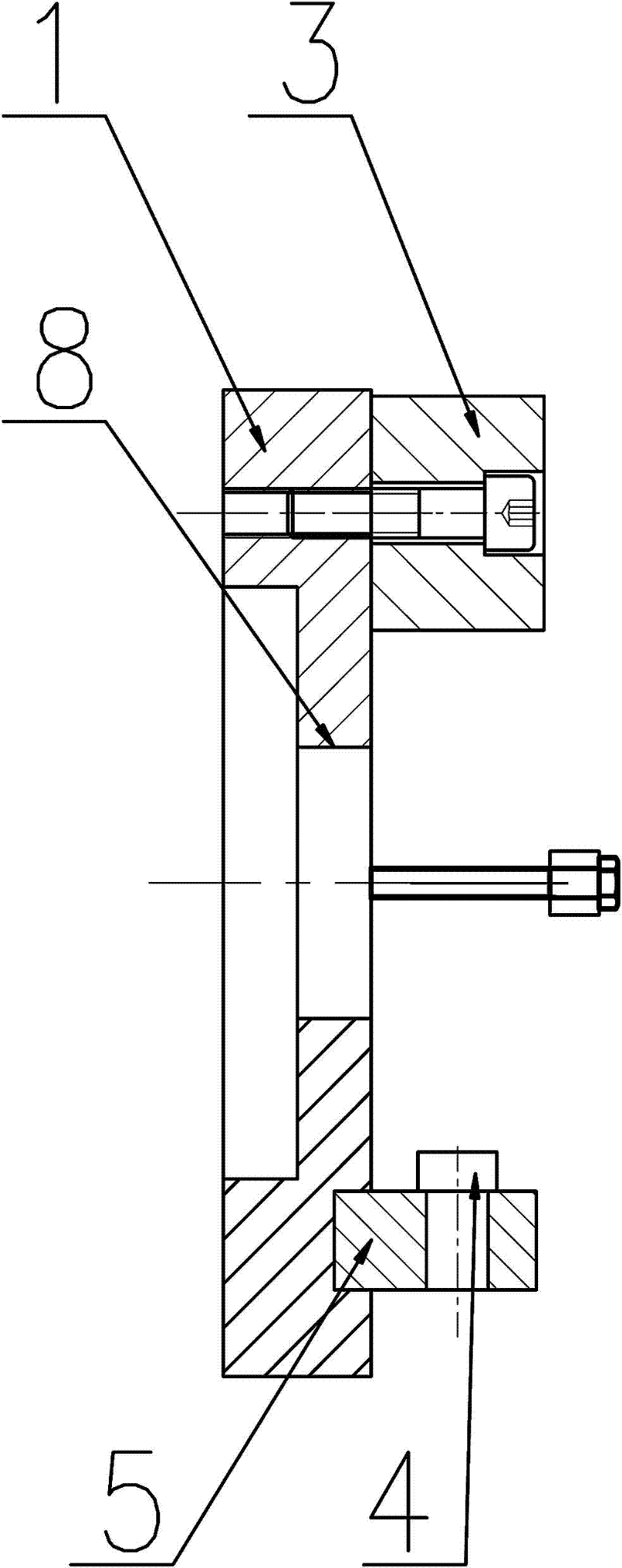

[0026] like figure 1 , figure 2 As shown in , a tooling for machining a bearing seat by a lathe includes a base body 1, which usually adopts a rotating body, such as a disc, which is convenient to be clamped on a lathe. The base body 1 is provided with a reference hole 8, and an installation block 5 is installed on the end surface of the base body 1, and the installation block 5 is provided with a positioning key 4 and at least one fixing hole 6;

[0027] A plurality of pressing plates 2 are also arranged on the end surface of the base body 1 . A plurality of bolts are arranged on the end face, and the pressing plate 2 is installed on the bolts, and the pressing plate 2 is provided with a chute, so that the length of the pressing plate 2 can be adjusted.

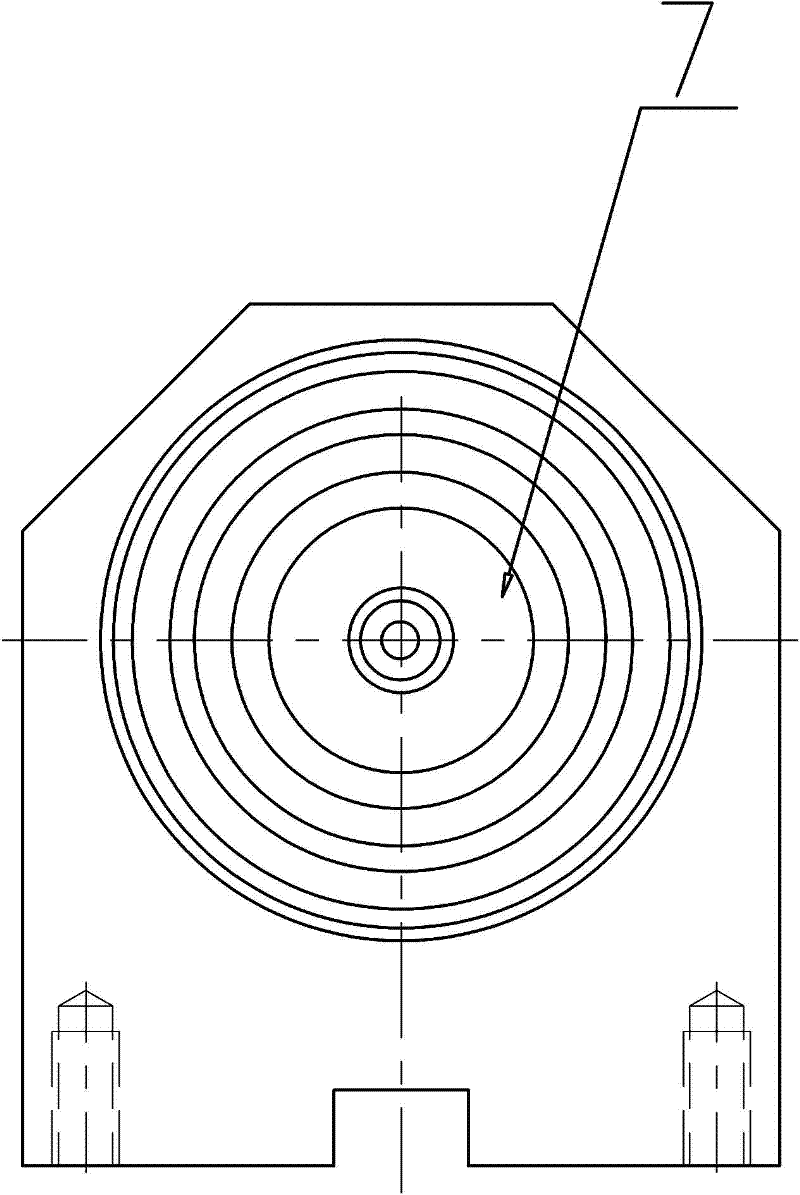

[0028] On the base body 1 , a counterweight 3 is provided opposite to the installation block 5 . The set counterweight 3 can avoid the unbalance on the circumference after the bearing housing 7 is installed, thereby caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com