Integral propeller hub body of marine propeller

A propulsion, integral technology, applied in ship propulsion, rotary propulsion, propulsion components, etc., can solve the problems of the clearance between the oil cylinder body and the propeller hub body, the plastic deformation of the screw, the eccentricity of the installation of the oil cylinder, etc. Friction loss, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

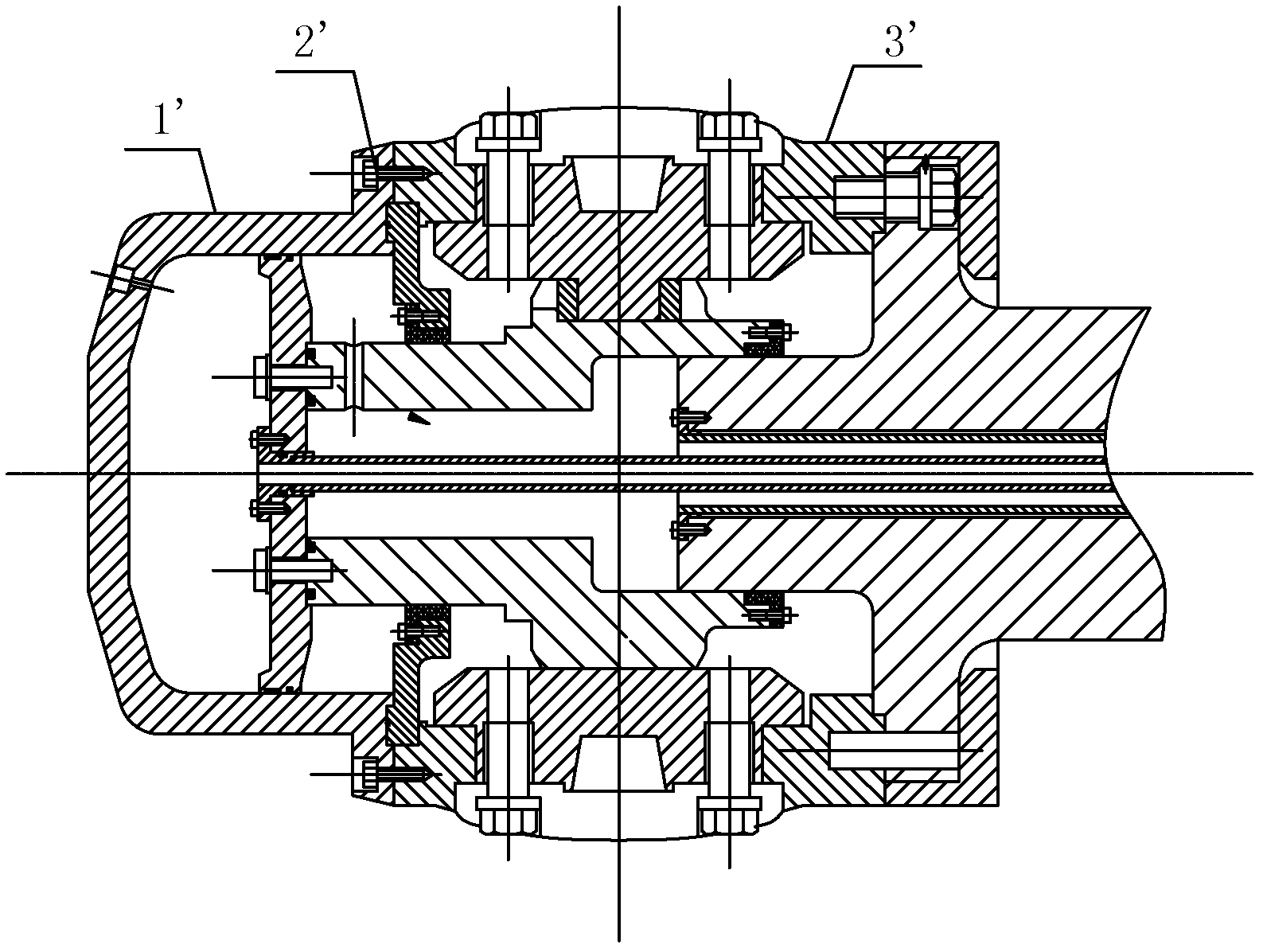

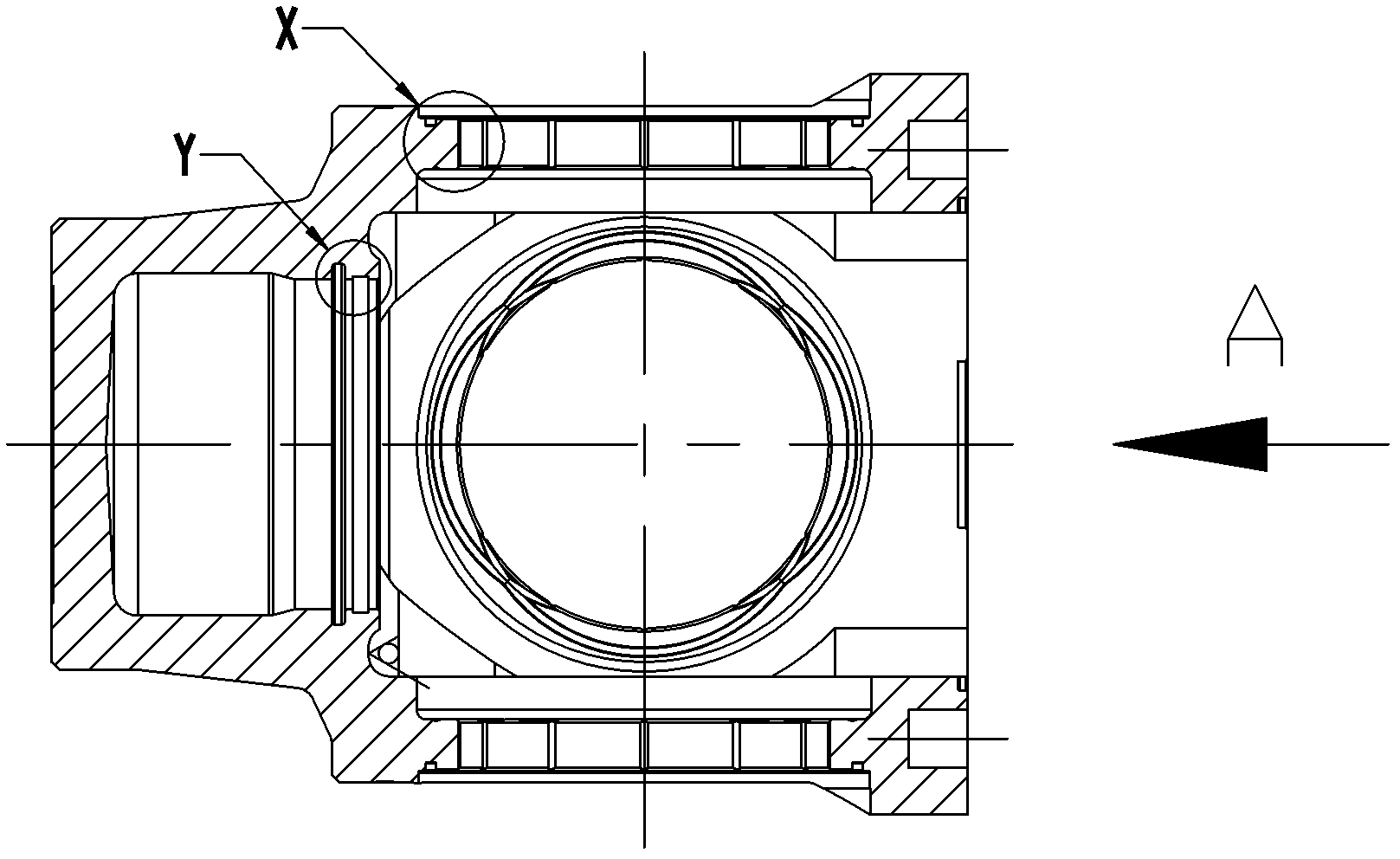

[0025] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

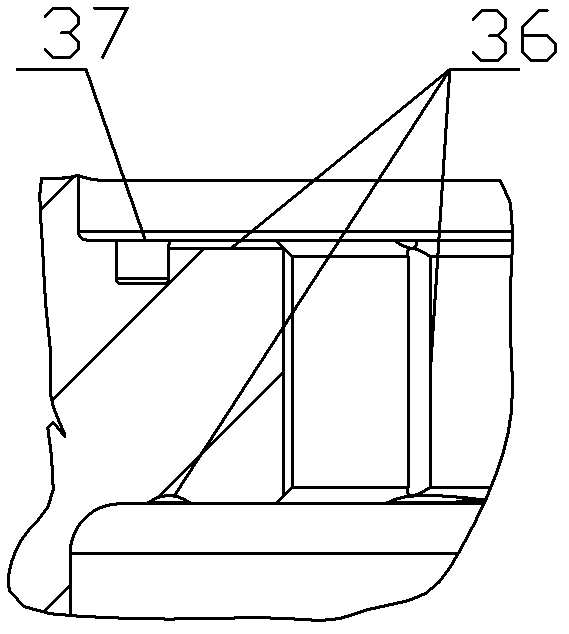

[0026] Such as Figures 2 to 6 As shown, the integrated propeller hub body of the ship propeller of the present invention includes an oil cylinder body 31, a sphere part and a cylinder part arranged in sequence, and the oil cylinder body 31, the sphere part and the cylinder part are respectively set up along the axis. Cavity, while the inner cavity that the spherical part 32 offers is a positive prism, and the positive prism in the accompanying drawings is a positive quadrangular prism; It is set in a conical shape; the intersection of the inner cavity of the oil cylinder body 31 and the spherical part 32 is respectively provided with a wear-resistant ring groove 34 for installing a wear-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com