Vertical coil tongs having centering and guiding device

A guiding device and vertical roll technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of restricting the yield of cold-rolled products, increasing the labor workload of workers, and unfavorable continuous production, so as to achieve great promotion and application value and reduce The labor intensity of workers and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

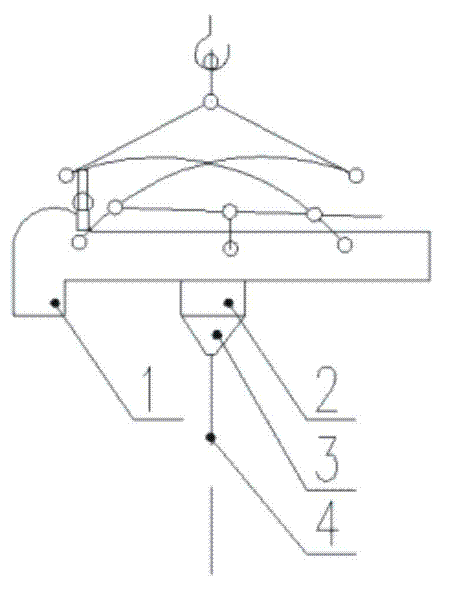

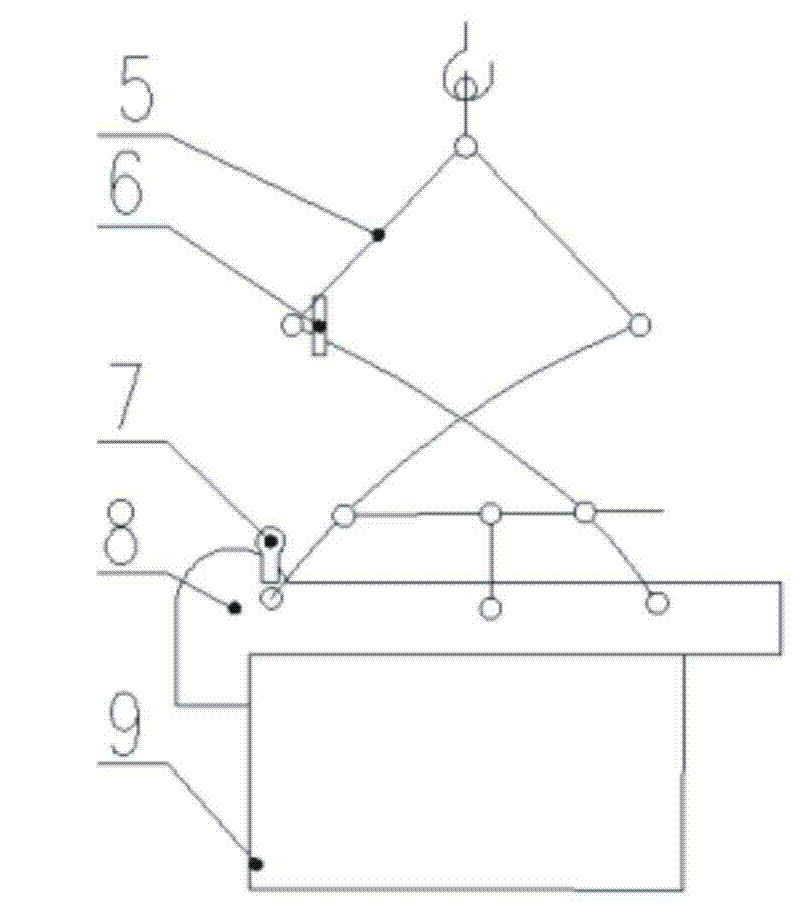

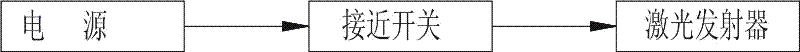

[0025] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a vertical roll tongs with a centering and guiding device, including a pincer arm 8, an outer jaw 1 located at the front end of the pincer arm 8, an inner jaw 2 movably connected to the pincer arm 8, and a control vertical roll clamp Open the tongs or the shutter for clamping the steel coil; the inner jaws 2 are provided with a centering and guiding device 3, and the centering and guiding device 3 includes a guide cylinder 11 with an overall inverted cone shape , the bottom of the guide cylinder 11 is provided with a groove, the groove is provided with a laser mounting seat 16, the laser mounting seat 16 is connected to the groove by threads, the laser emitter 17 is placed in the laser mounting seat 16, and the laser emitter The light beam 4 emitted by 17 coincides with the vertical line of the inner jaw 2; a baffle 15 is provided at the bottom of the l...

Embodiment 2

[0028] Embodiment 2, a vertical roll clamp with a centering and guiding device, including a clamp arm, an outer clamp tooth located at the front end of the clamp arm, an internal clamp tooth that is movably connected to the clamp arm frame, and controls the vertical roll clamp to open A controller for clamping or clamping steel coils; the inner jaws are provided with a centering and guiding device, and the centering and guiding device includes an overall inverted tapered guide cylinder, and the lower part of the guide cylinder There is a groove, and a laser mounting seat is provided in the groove. The laser mounting seat is connected to the groove through threads. The laser emitter is placed in the laser mounting seat, and the beam emitted by the laser emitter is perpendicular to the vertical line of the inner jaw. overlap; a baffle plate is provided on the lower part of the laser mounting seat, and a hole corresponding to the laser transmitter is provided on the baffle plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com