Automatic digital control molding machine

A forming machine and automatic technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of poor working environment, scrap rate, and easy safety accidents for operators, so as to prevent workers from being trapped The effect of injury, low scrap rate, and long continuous operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

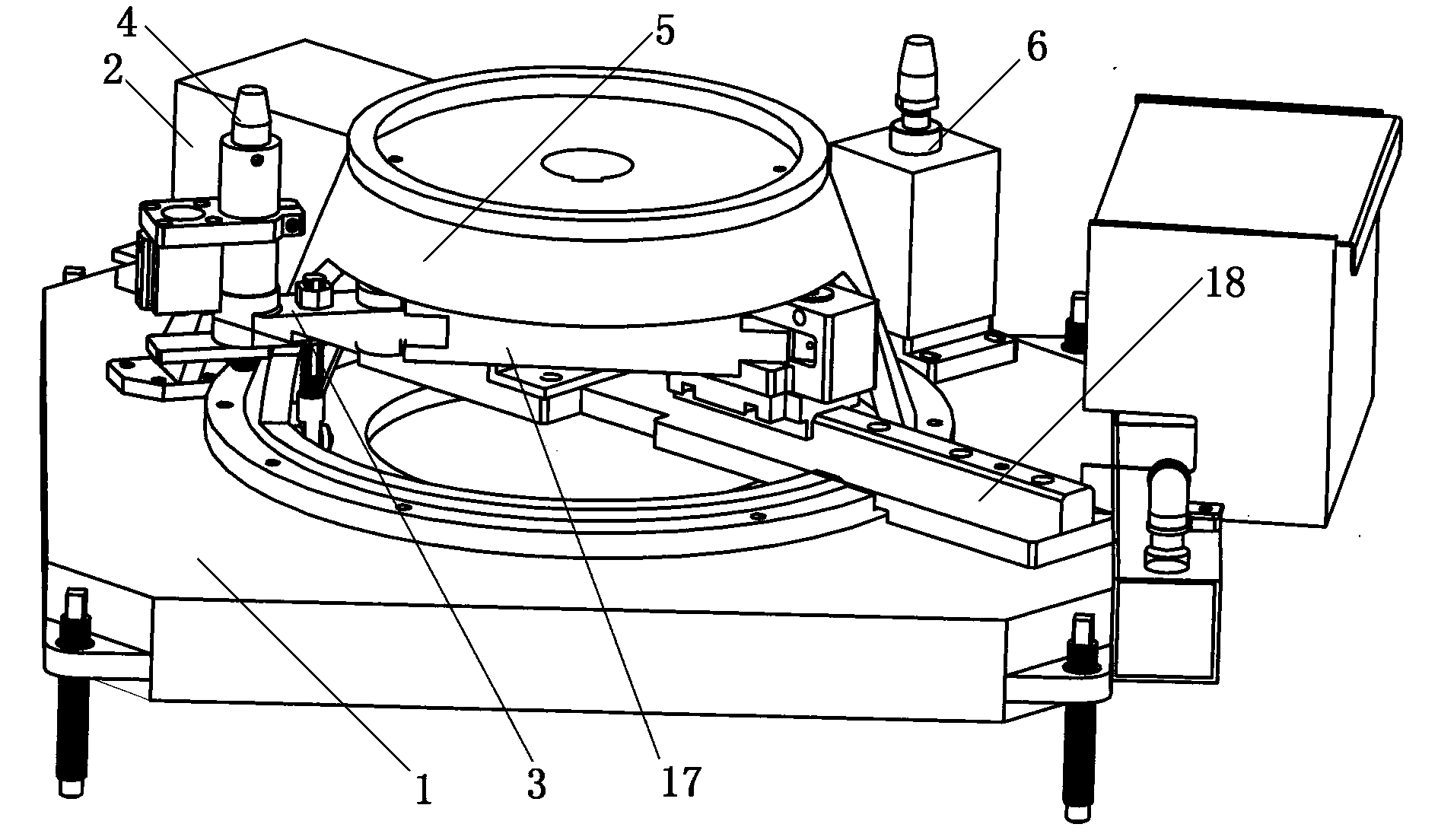

[0010] Embodiment: In this embodiment, four stations are taken as an example, and the number of stations can be adjusted as required in actual use.

[0011] The piston of the transmission cylinder 2 on the base 1 moves on the line rail 18, and through the linkage of the connecting rod 17, the swing rod 3 and the pull rod 4, the circular rotation of the support 5 is realized automatically. In addition, the brake device 6 brakes once when the swing angle is 90 degrees, so as to realize the stop of the rotation. The above parameters are all numerically controlled and can be adjusted of course.

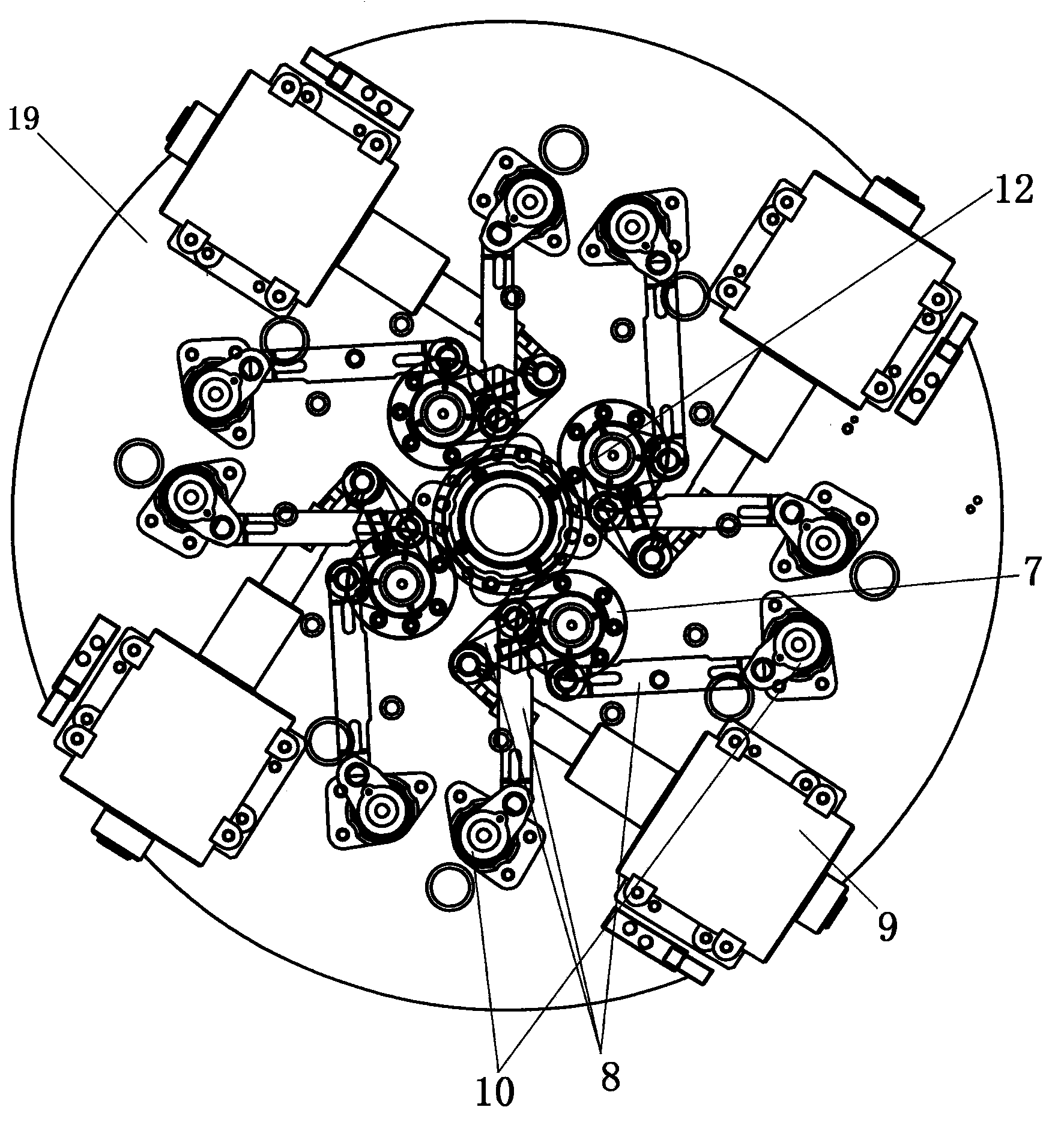

[0012] The middle disc 19 rotates with the support 5 .

[0013] The hinge 7 is a three-layer structure, which connects the piston of the cylinder 9 and the two rotating rods 10 through the connecting rod 8 respectively. The piston of the cylinder 9 advances or retreats, drives the hinge 7 to rotate forward or reversely, and the hinge 7 drives the two rotating rods 10 to rotate forwardly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com