Water sealing type cover plate device in coal bearing device of coal gas producer

A gas generator and cover plate device technology, applied in the field of coal bearing devices, can solve the problems of threatening the health of operators, poor sealing performance, gas leakage, etc., and achieve the effect of good sealing performance, ingenious and reasonable structure, and health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the specific drawings and embodiments.

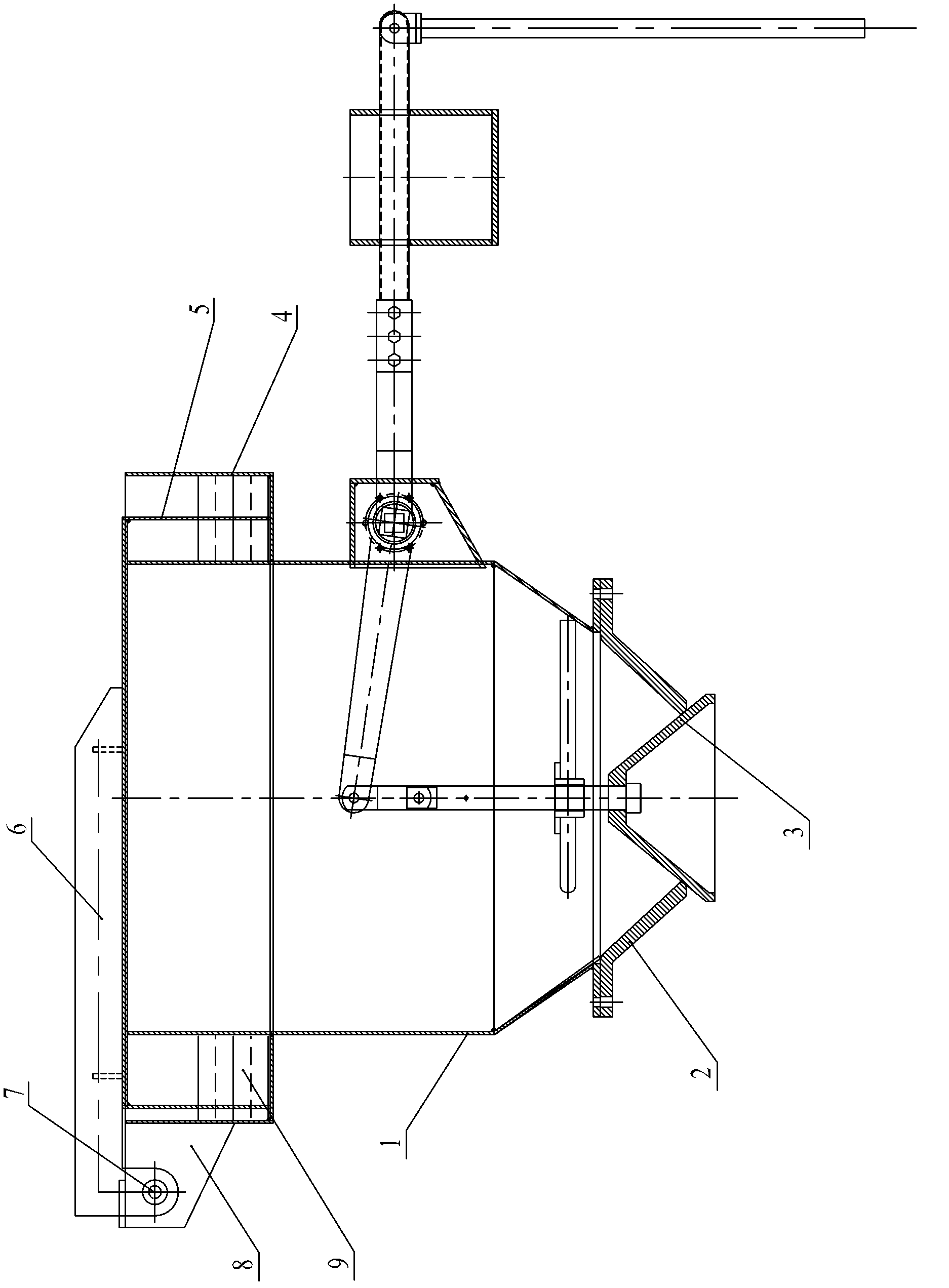

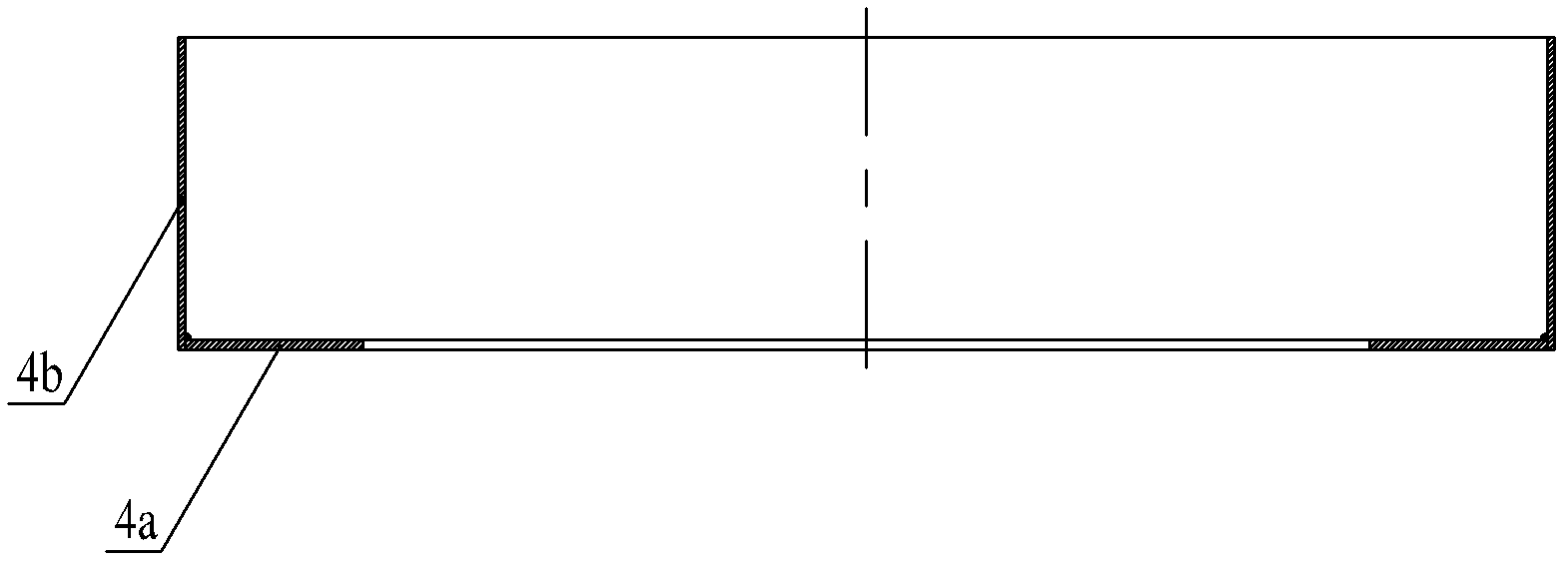

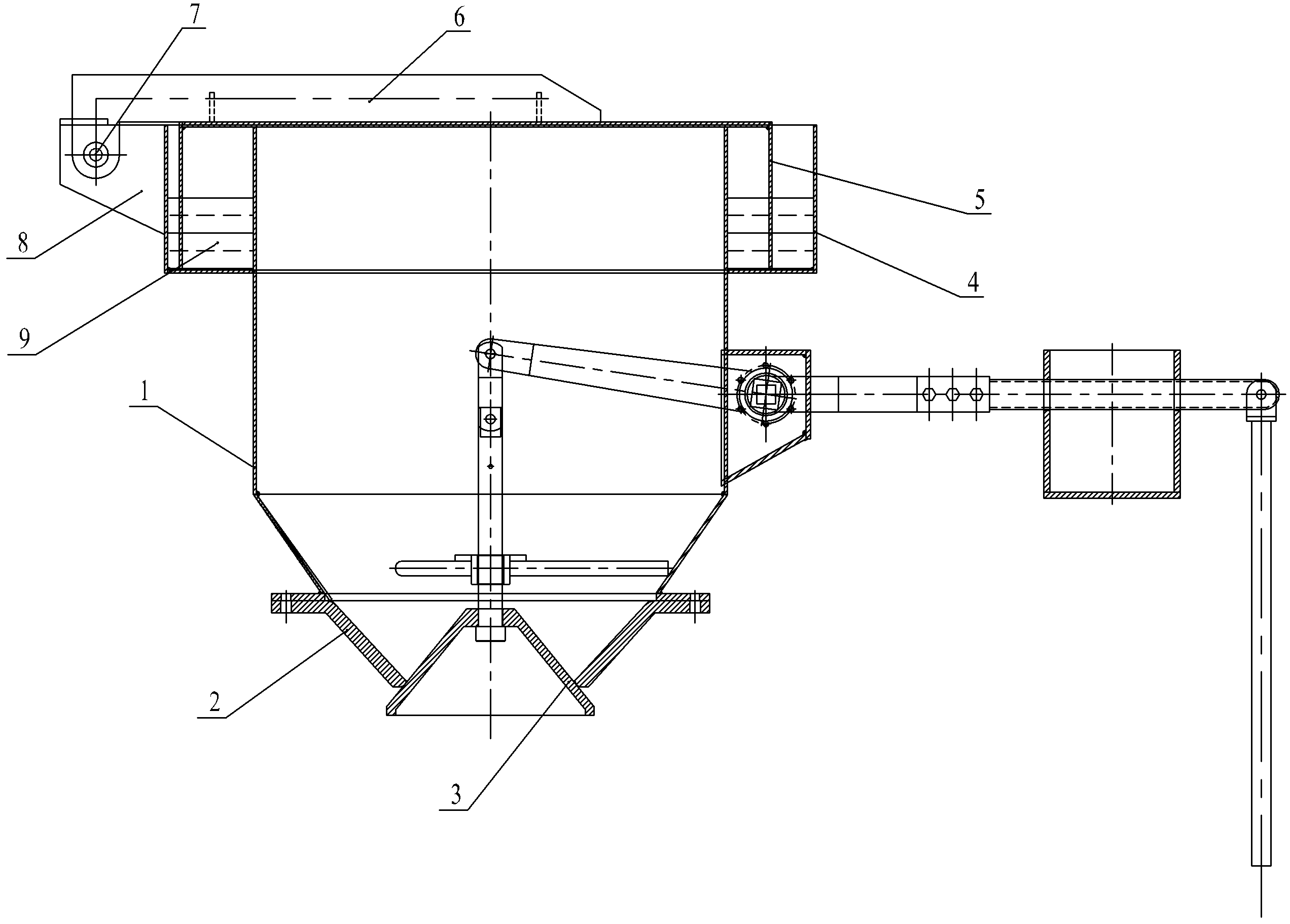

[0014] like figure 1 , figure 2 As shown, the water-sealed cover plate device is used in the coal bearing device of the gas generator to prevent the gas in the coal bearing hopper 1 from leaking out. The water seal type cover plate device is mainly composed of a water seal seat 4, a water seal cover 5, a boom 6, a boom shaft 7 and a cover lifter 8. The bottom plate 4a of the water seal seat 4 is welded and fixed on the outer wall of the coal bearing bucket 1 , an annular open chamber 9 is formed between the annular side wall of the water seal seat 4 and the outer wall of the coal hopper 1, and the open chamber 9 is filled with water; the water seal cover 5 is open at one end and closed at the other end The radial dimension of the water seal cover 5 is smaller than the radial dimension of the water seal seat 4; the cover lifter 8 is welded on the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com