Method and device for automatically resetting zero position on hydraulic transmission device

A hydraulic transmission device and automatic technology, applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problems of complex system structure, large three-dimensional space, and low integration, and achieve simple implementation structure and reduce three-dimensional Space, the effect of improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

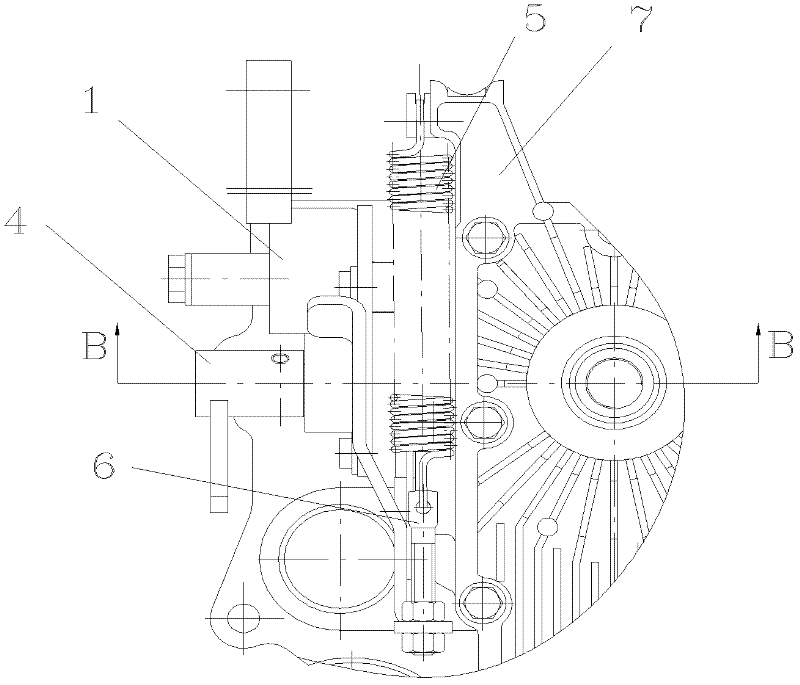

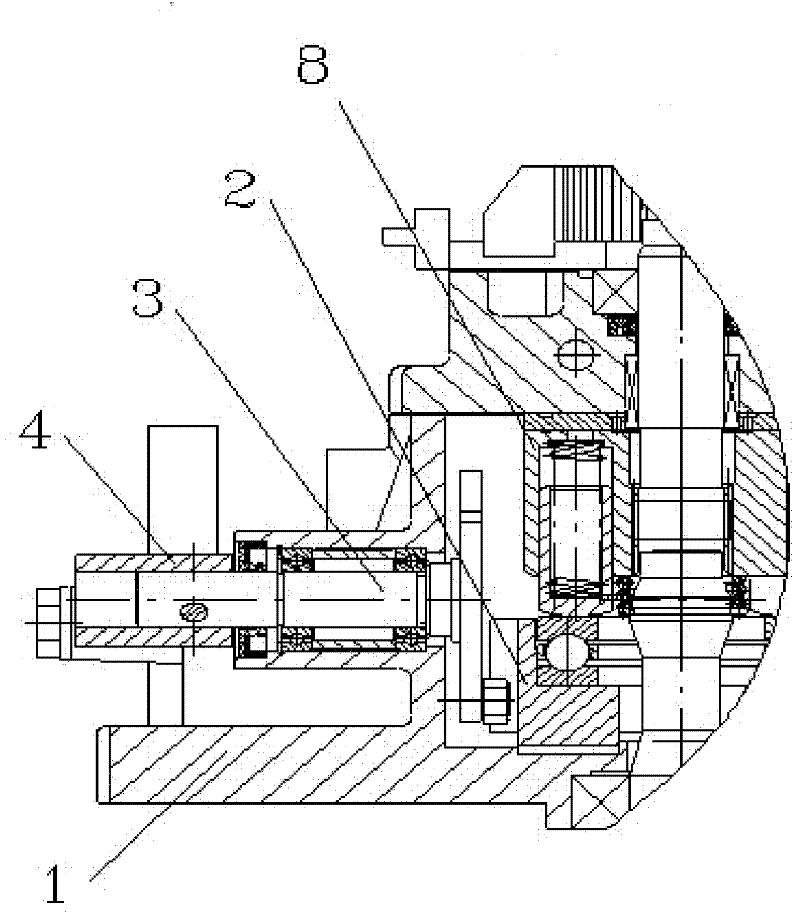

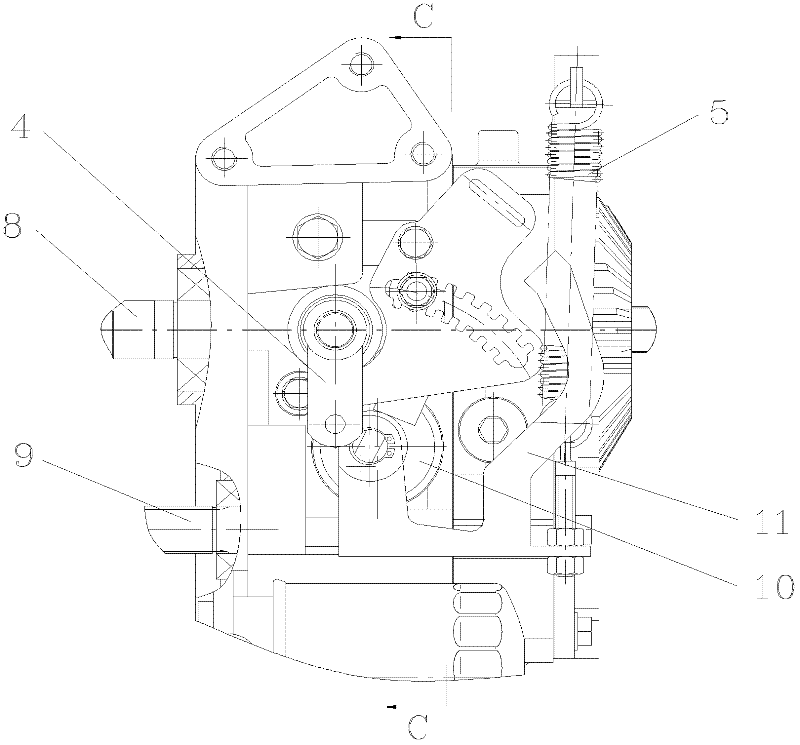

[0023] Example. An automatic centering method on a hydraulic transmission device, characterized in that: in the pump cavity of the hydraulic transmission device, the handle on the hydraulic transmission device is reset to the neutral position by the automatic centering device, and the hydraulic oil in the pump cavity is used to Lubricate and maintain the automatic center reset device, and at the same time improve the integration. The method of returning the handle on the hydraulic transmission device to the neutral position by the automatic center reset device is to use the return spring to drive the intermediate body through the bracket, so that the bearing on the intermediate body returns to the U-shaped arc track of the return shaft. On the neutral position, the handle connected to the return sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com