Concurrent flow heat exchanger

A technology of parallel flow heat exchangers and flow tubes, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problem of deteriorating the flow effect of heat exchangers, reducing the heat transfer effect of heat exchangers, and reducing compression Oil level and other issues, to achieve the effect of simple and reasonable structure, wide application range, and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

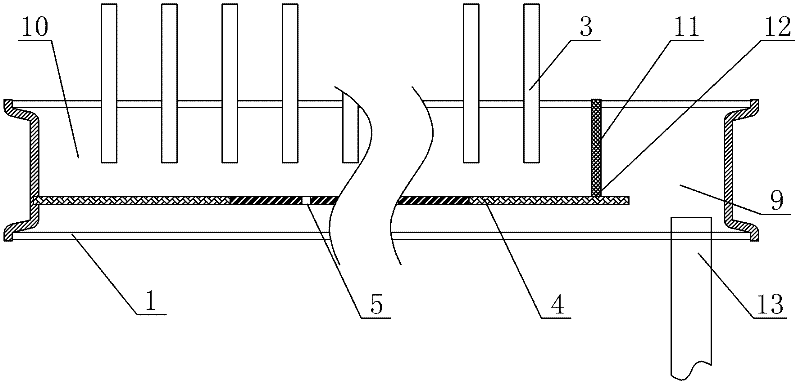

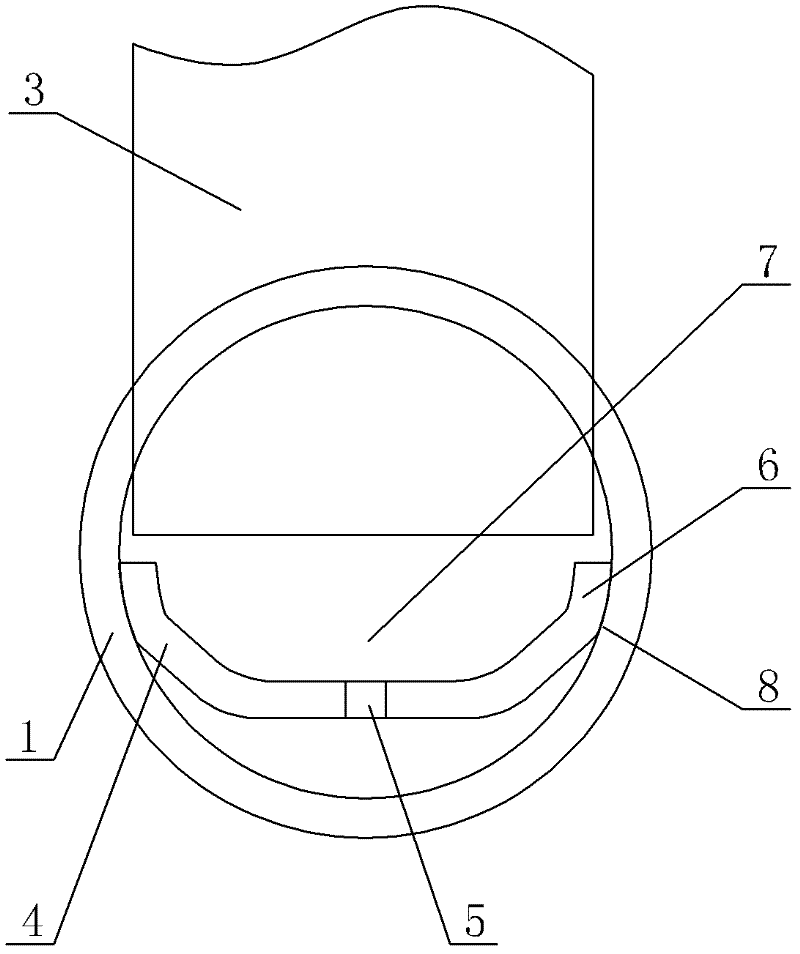

[0027] see Figure 1-Figure 3 . A parallel flow heat exchanger comprising a lower header 1, an upper header 2, several flat tubes 3 arranged between the upper and lower headers, fins arranged between adjacent flat tubes 3, A flow equalizer 4 is arranged inside the lower header 1 , and the flow equalizer 4 divides the lower header 1 into a first cavity 9 connected to the refrigerant pipe 13 and a second cavity 10 connected to the flat tube 3 . The width direction of the flow equalizer 4 is a concave curved surface, and is concave to the lower side of the collector 1 . The wall surface of the concave part of the flow even plate 4 forms a channel 7 with a narrow bottom and a wide top in the second cavity 10 . Specific as figure 2 As shown, a through hole 5 is provided in the concave part of the uniform flow plate 4. When the heat exchanger is used as a condenser, due to the curved surface of the flow uniform plate 4, the refrigerated oil condensed and collected from the flat tu...

no. 2 example

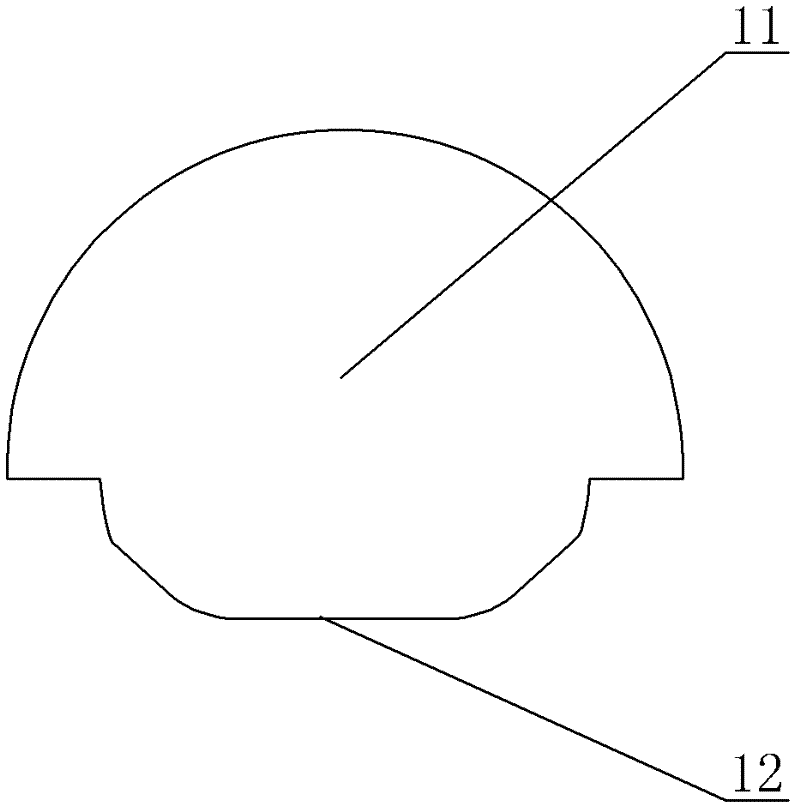

[0032] like Figure 4 , Figure 5 As shown, the shape of the flow equalizer 4 in the width direction of this embodiment is a convex curved surface, and the flow equalizer 5 divides the header 2 into a first cavity 9 connected to the refrigerant pipe 13 and a second cavity 10 connected to the flat tube 3 , the flow equalizer 4 is protruding to the side of the flat tube 3, and a through hole 5 is provided at the place where the flow equalizer 4 is easy to collect oil, that is, at the bend on both sides of the flow equalizer 4 that protrudes to the flat tube 3, specifically as Figure 4 As shown, through holes 5 are provided at the bends on both sides of the flow sharing plate 4 . When the heat exchanger is used as a condenser, due to the curved surface of the flow uniformity plate 4, the refrigerated oil condensed and collected from the flat tubes 3 will be collected in the lower part of the channel 7, so as to flow into the lower side of the flow uniformity plate 4 through the...

no. 3 example

[0037] see Image 6, The main difference between this parallel flow heat exchanger and the second embodiment is that two rows of through holes 5 are arranged alternately along the direction of the axis of the lower header 1 on the curved surfaces on both sides of the flow equalizer 4 . In this way, the distance between the through holes 5 in each row can be enlarged, the total number of holes can be reduced, and the speed of the refrigerant flowing out from the through holes 5 can be increased, thereby further increasing the uniformity of gas-liquid mixing and improving the heat exchange efficiency of the heat exchanger. Other unmentioned parts are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com