Jet type condenser

A technology of jet condenser and water chamber, which is applied in the field of exhaust steam cooling system, can solve the problems of increasing the load of the air extraction pump, increasing the pressure of the condenser, and affecting the performance of the condenser, so as to reduce the degree of supercooling, The effect of reducing heat consumption and facilitating large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

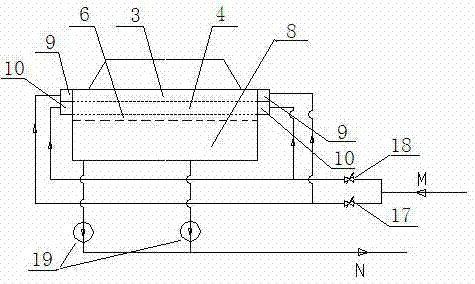

[0040] Such as Figure 6 As shown, it is a schematic diagram of the first cooling water system of the multi-layer inner water chamber jet condenser cooling water system of the present invention. It is equipped with a set of power equipment, that is, equipped with a cooling water pump 15 and a water turbine 14. The system is generally a multi-layer inner water chamber spray condenser cooling water system for small units. The cooling water system only includes a circulating water pump 15, a water turbine 14, a cooling tower, a condenser and the pipelines and flow regulating elements between them, forming a circulating loop. The pipeline at the rear end of the turbine 14 is divided into three branch pipes X, Y and Z on one side to enter the condenser, wherein the water inlet pipe X of the upper outer water chamber enters the upper outer water chamber 9, and the upper chamber water inlet pipe Y of the lower outer water chamber Enter the upper cavity 10-1 of the lower outer water ...

Embodiment 2

[0043] Such as Figure 7 As shown, it is a schematic diagram of the second structural form of the multi-layer inner water chamber jet condenser cooling water system of the present invention, which is generally a multi-layer inner water chamber jet condenser cooling water system of a medium-sized unit. The system includes two sets of power equipment, that is, two parallel circulating water pumps 15-1, 15-2 and two parallel water turbines 14-1, 14-2. That is to say, there are two water turbines 14-1 and 14-2 connected in parallel on the cooling water input pipeline M to coordinately control the cooling water volume and work capacity, and two circulating water pumps 15-1 and 15-1 are connected in parallel on the circulating water output pipeline N. 15-2, while pumping circulating water into the cooling tower.

[0044] In this embodiment, the pipelines at the rear ends of the turbines 14-1 and 14-2 are divided into six branch pipes to enter the condenser, wherein the water inlet ...

Embodiment 3

[0048] As shown in Figure 8, it is a schematic diagram of the third structural form of the multi-layer inner water chamber jet condenser cooling water system of the present invention, which is generally a multi-layer inner water chamber jet condenser cooling water system of a large unit. The cooling water system only includes three sets of power equipment, that is, three parallel circulating water pumps 15-1, 15-2, 15-3 and three parallel water turbines 14-1, 14-2, 14-3. That is to say, three water turbines 14-1, 14-2, and 14-3 are connected in parallel on the cooling water input pipeline M to coordinately control the cooling water volume and work capacity, and three circulating water pumps 15-1 are connected in parallel on the circulating water output pipeline N. 1, 15-2, 15-3, pump circulating water into the cooling tower at the same time.

[0049] In this embodiment, the design of the pipelines at the rear ends of the water turbines 14-1, 14-2 and 14-3 is the same as that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com