Testing device for testing creeping property of high-temperature integral flanged joint

A technology of integral flange and creep performance, which is applied in the direction of measuring devices, optical devices, and the ductility of test materials, etc., can solve the problems of low test accuracy, backward test methods, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

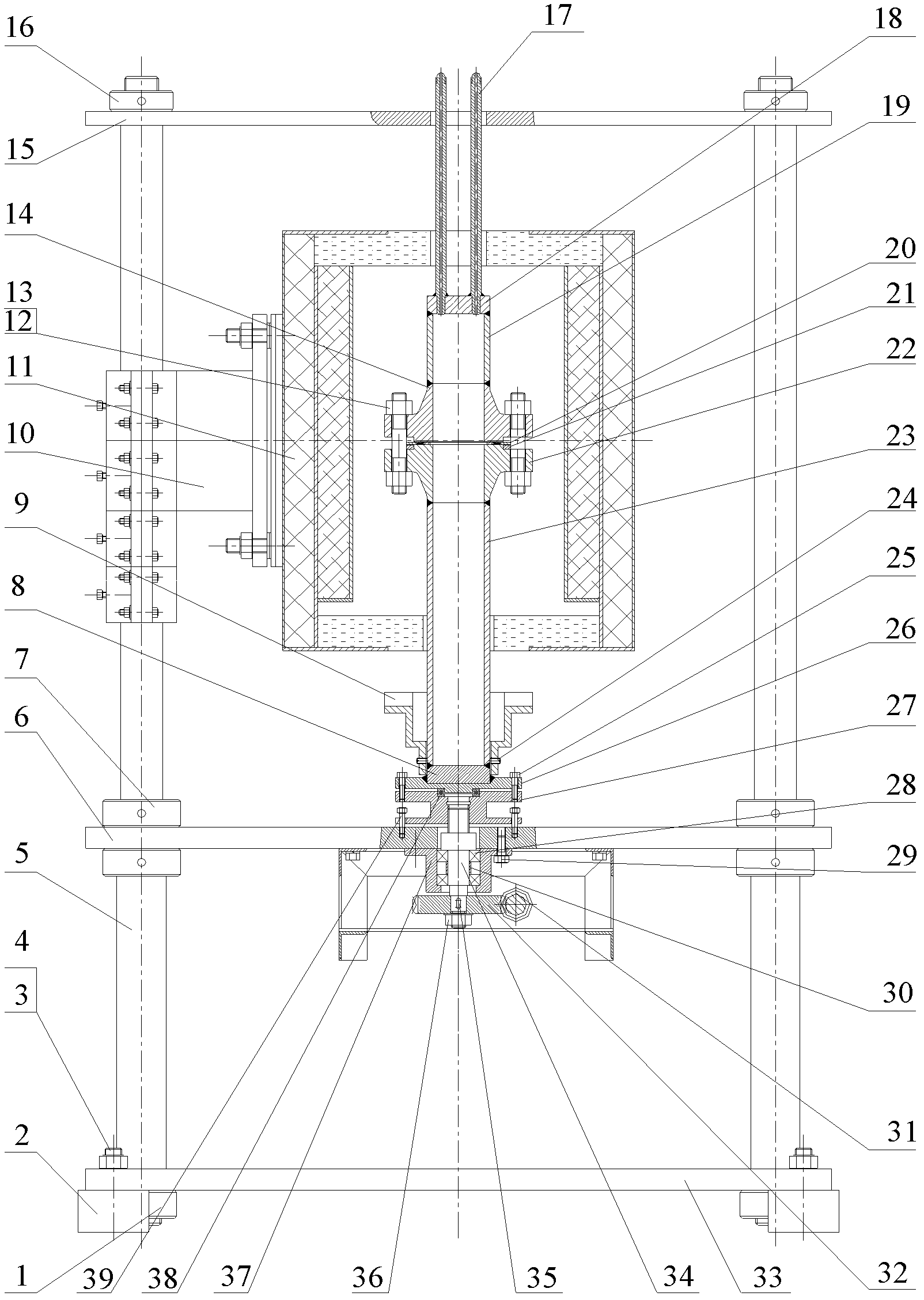

[0037] The present invention will be further described below in conjunction with accompanying drawing:

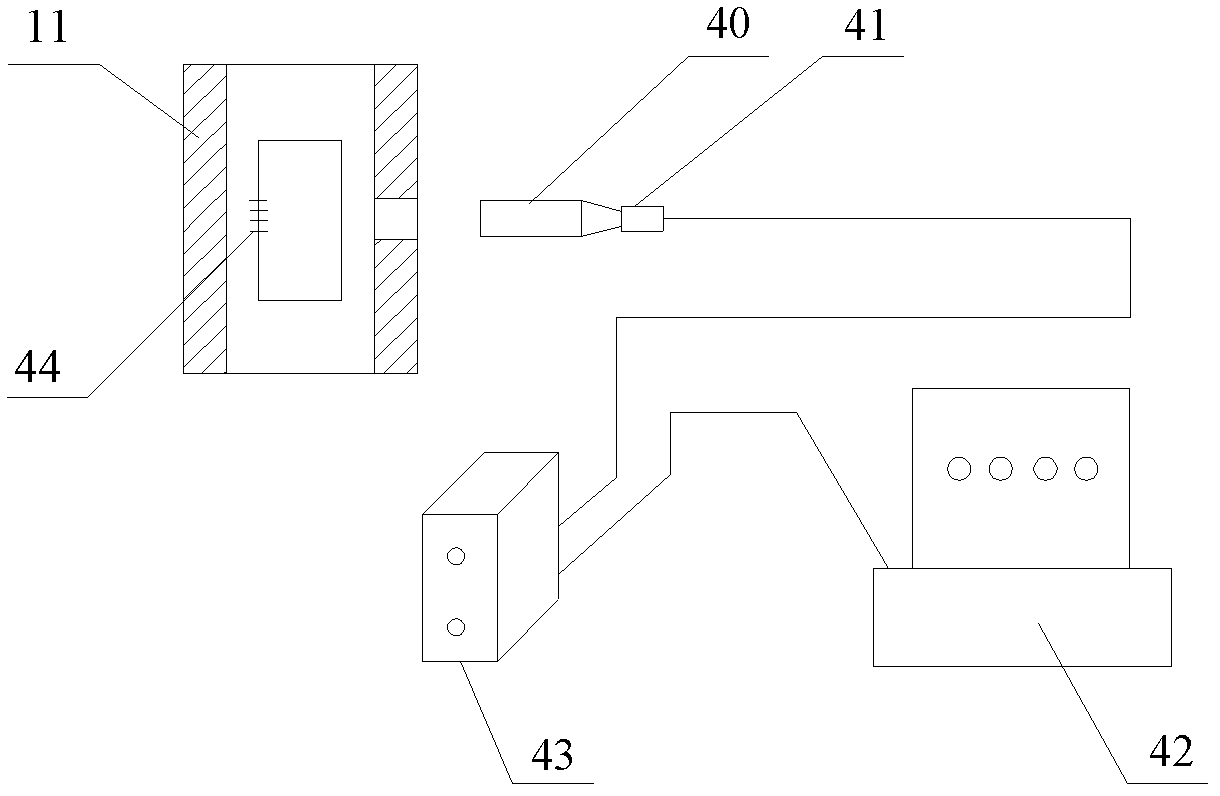

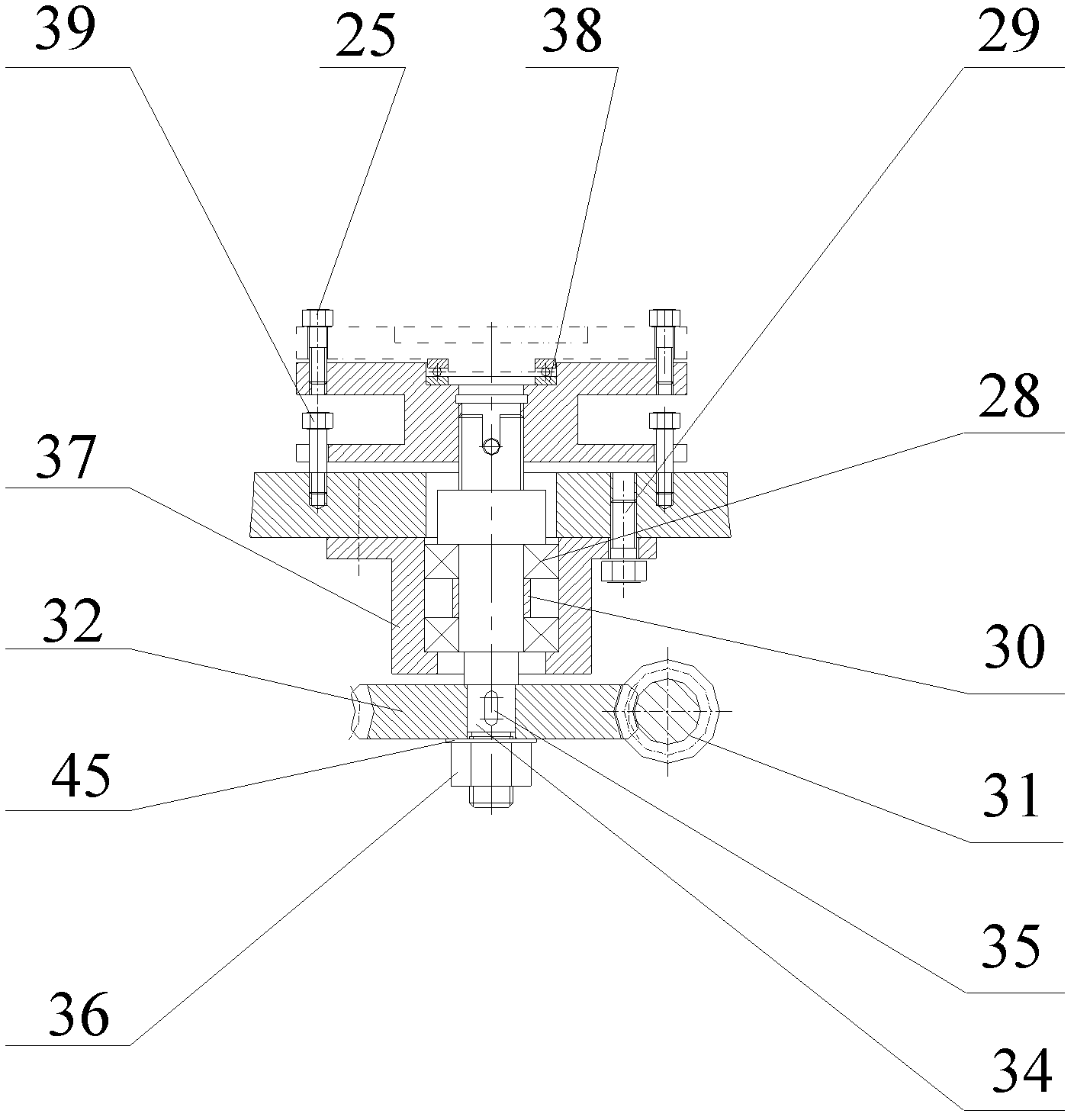

[0038] like figure 1 As shown, a test device for testing the creep performance of a high-temperature integral flange joint is characterized in that it includes an upper flange 14 and a lower flange 22, and a test gasket 20 is loaded between the upper flange 14 and the lower flange 22, and the upper flange 14 and the lower flange 22 are loaded. The flange 14 and the lower flange 22 are arranged in the electric heating furnace 11, the upper flange 14 and the lower flange 22 are connected and fixed by the studs 12, and the upper flange 14, the lower flange 22 and the studs 12 are fixed Many places are marked with quartz optical fiber 44 to measure the deformation of the upper flange 14, the lower flange 22 and the double-ended stud 12. There is a measuring device in the gap between the end of the lower flange 22 and the double-ended stud 12. The ring 21, the test gasket 20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com