Multi-loop comprehensive control device for coal mine fully-mechanized excavation working surface

A technology of integrated control and working face, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as cumbersome wiring, difficult relocation, and restrictions on the popularization of excavation working faces, so as to avoid misoperation and comprehensive The effect of improving the technical level and avoiding electric leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

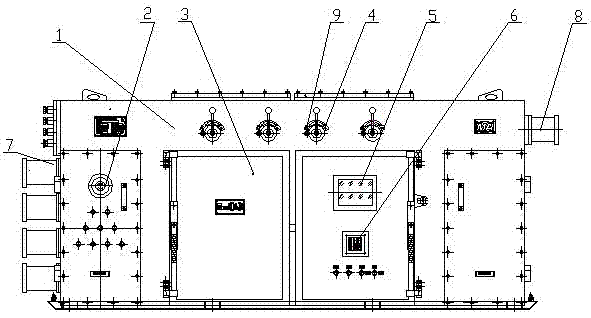

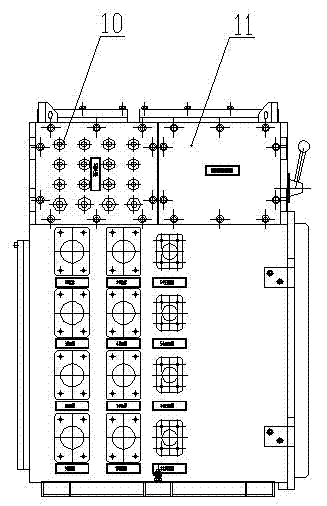

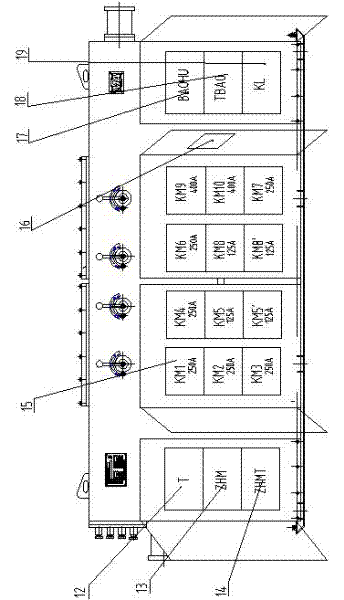

[0026] see Figure 1-Figure 8 , including an explosion-proof enclosure, the explosion-proof enclosure includes a disconnector chamber 1 and a main control chamber 3, and a group of disconnectors 4, a main terminal and a nine-core terminal are arranged in the disconnector chamber 1. Each isolating switch 4 is connected to a group of driver units 15, and all the driver units 15 are arranged in the main control cavity, and each driver unit 15 is connected to a protection card unit 17, and the protection card unit 17 The protection card power supply unit 18 is connected, the protection card unit 17 is connected to the PLC controller 16, and the PLC controller 16 is connected to the keyboard 6 and the liquid crystal display 5 .

[0027] There are 4 isolating switches, which are respectively isolating switches QS1, QS2, QS3, QS4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com