Automatic monitoring device for mining explosion door

An automatic monitoring and mining explosion-proof technology, applied in door/window accessories, comprehensive factory control, power control mechanism, etc., can solve the problems of heavy weight, unable to reset correctly, difficult to open manually, etc., to eliminate abnormal large number of interference, The effect of eradicating false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

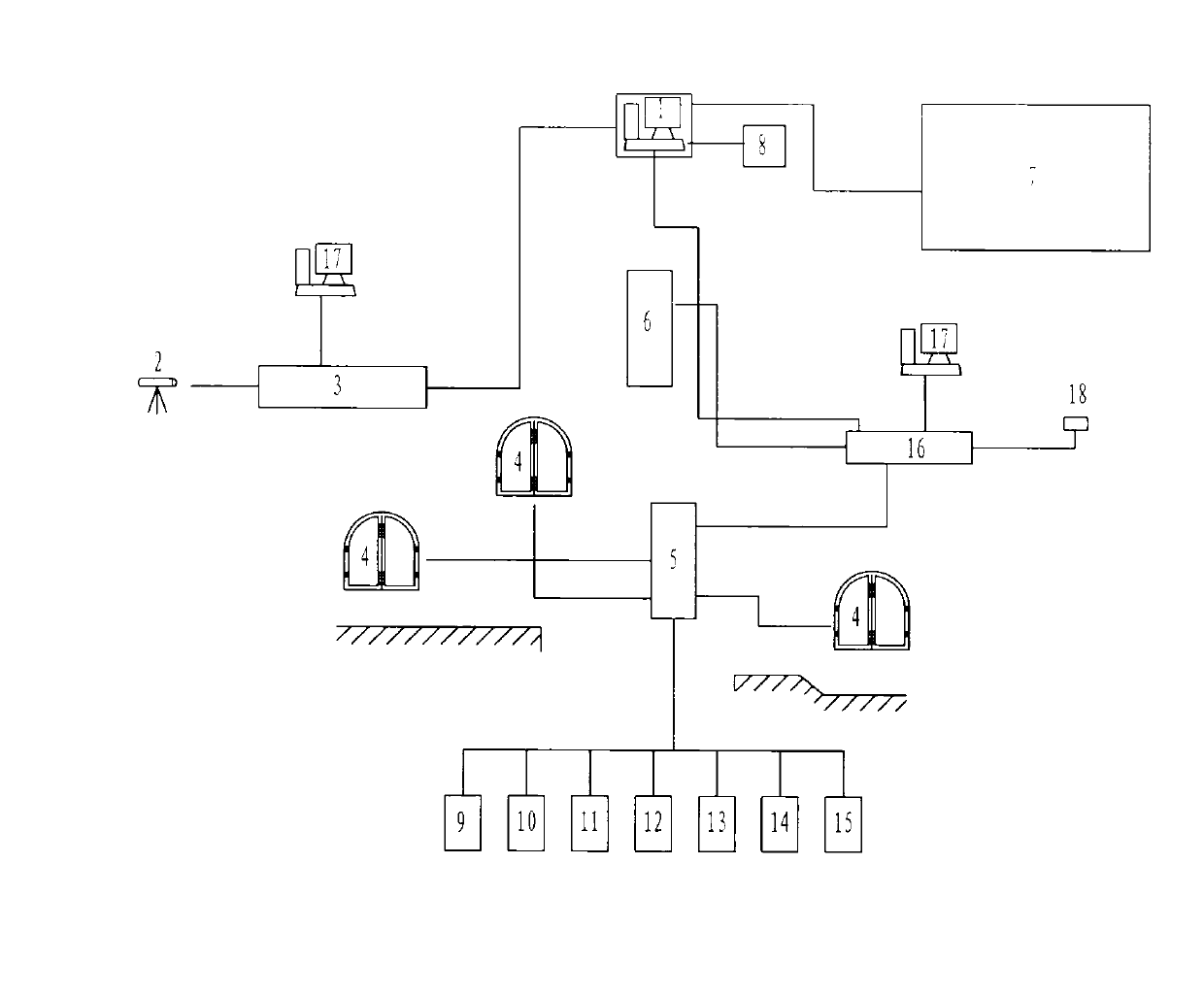

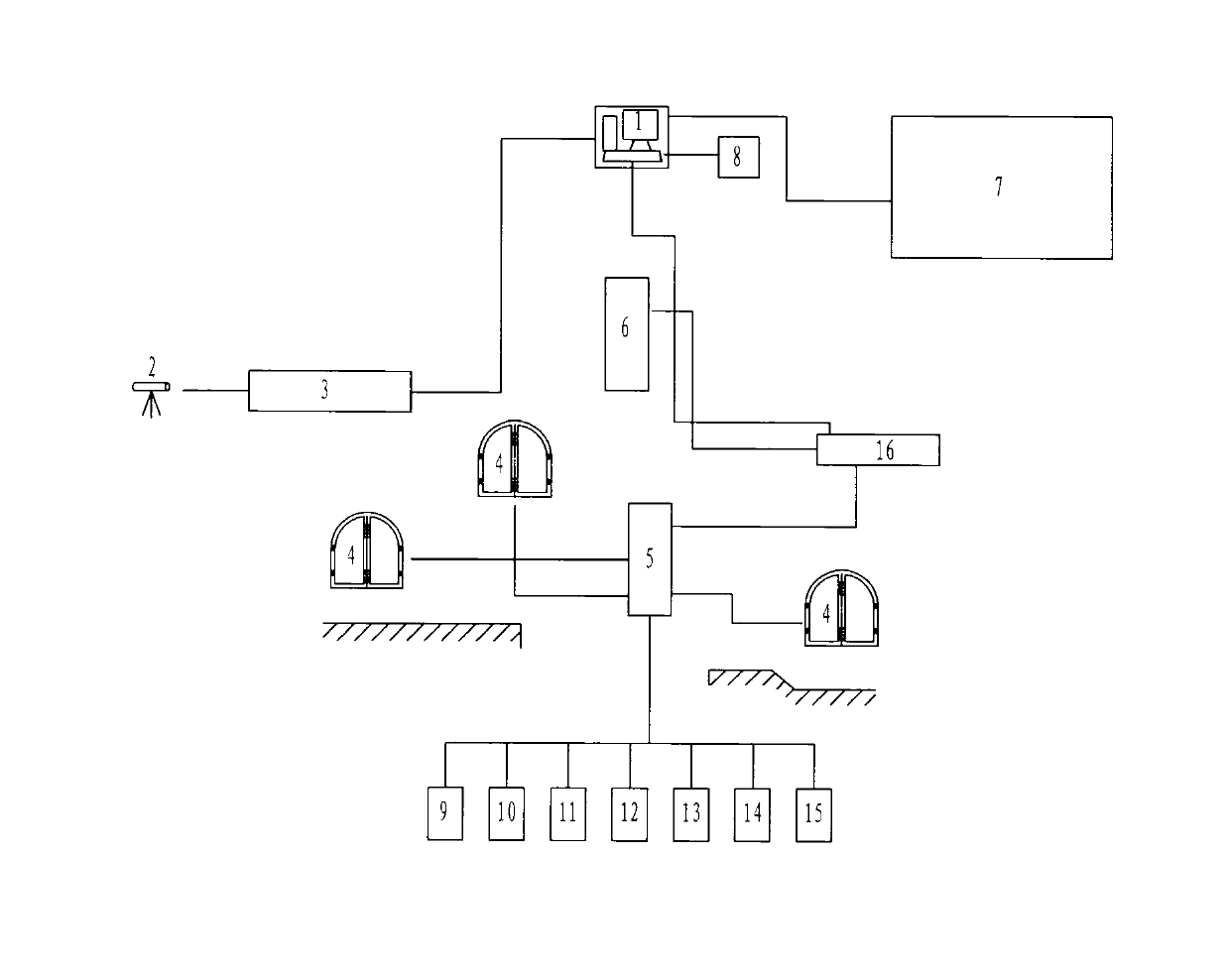

[0018] Such as figure 1 As shown, the automatic monitoring device for mine explosion-proof doors in the present embodiment includes at least one monitoring host 1, a display screen 7 and a printing device 8, wherein: it also includes at least one camera device 2, video processor 3, wind Well explosion-proof door 4, PLC control cabinet 5, server 6, wind speed sensor 9, carbon monoxide sensor 10, smoke sensor 11, gas sensor 12, temperature sensor 13, positive pressure sensor 14, negative pressure sensor 15 and switch 16; camera equipment 2 Information output end is connected with the information input end of video processor 3, so that the video information collected by camera equipment 2 is passed to video processor 3; The information output end of video processor 3 is connected with the video information input end of monitoring host computer 1, so that The information processed by the video processor 3 is transmitted to the monitoring host 1; the information output terminals of...

Embodiment 2

[0020] Mine explosion-proof door automatic monitoring device in the present embodiment, it also comprises at least one network terminal 17 and at least one router 18, the information input end of network terminal 17 is respectively with the information output end of video processor 3 and the wide area network interface of switchboard 16 (WAN) connection in order to monitor and collect the information; the information input end of the router 18 is connected to the wide area network interface (WAN) of the switch 16 so as to enter the monitoring system through any terminal computer in the network. The rest of the structure of the automatic monitoring device for explosion-proof doors for mines in this embodiment is the same as that of the automatic monitoring device for explosion-proof doors for mines in Embodiment 1.

[0021] The working principle of the present invention is:

[0022] Set up a control cabinet in the power distribution room, the control cabinet is controlled by PL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com