Hydraulic power assisting device for automatic backwash filter

A booster device and backwashing technology, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve problems such as unfavorable installation and placement of filters, increased cost of filters, easy damage of hydraulic motors, etc., to achieve suitable Effects on promotion, saving money, improving utilization rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

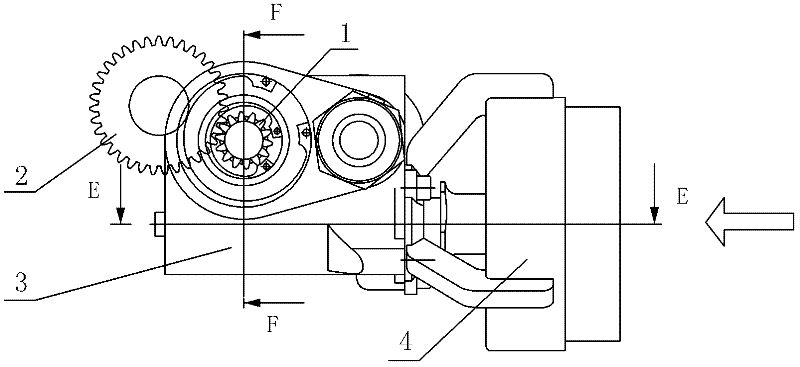

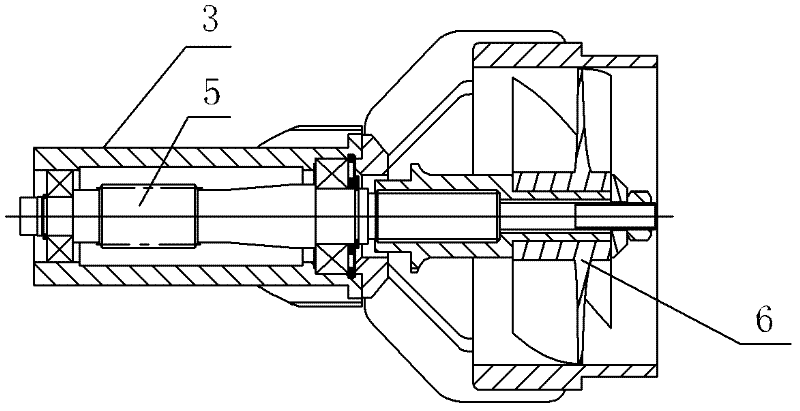

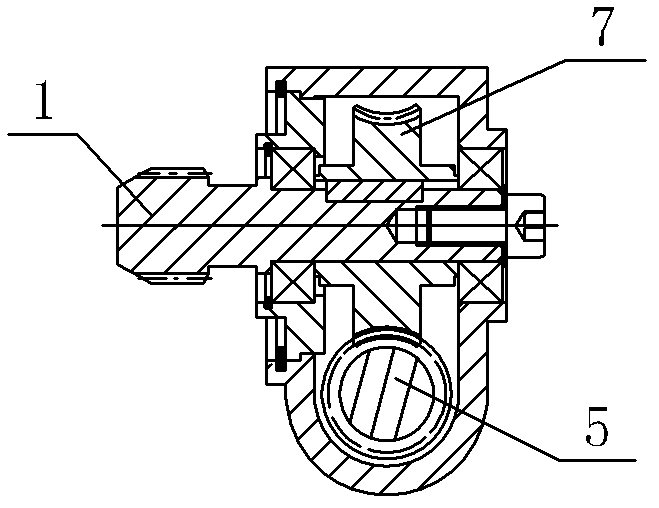

[0017] Such as Figure 1-Figure 4 As shown, the backwash filter distributor 8 is fixedly equipped with a large gear 2, and a hydraulic transmission box 3 and a blade frame 4 are arranged inside the backwash filter, and the blade frame 4 is arranged on the oil inlet 9 of the backwash filter, and the The impeller 6 is coaxial with the worm 5 of the hydraulic transmission box 3, and the impeller 6 is set on the center line of the oil inlet 9, and the turbine 7 is arranged inside the hydraulic transmission box 3, and the turbine 7 is coaxial with the pinion 1 outside the hydraulic transmission box 3 , the pinion 1 meshes with the bull gear 2.

[0018] The impeller 6 is provided with 2-8 rotating blades.

[0019] The small gear 1 and the large gear 2 are reduction transmissions. The worm-worm-gear transmission also acts as a reducer to adapt to the speed and stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com