Vertical guide structure of saw frame of stone sawing machine

A vertically oriented stone sawing machine technology, which is applied to stone processing tools, stone processing equipment, and work accessories, can solve the problems of inconsistent wear of the left and right belts, inconvenient maintenance work, and large footprint of the stone sawing machine. Repair and maintenance work, simple and reasonable structure, fast sawing stone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

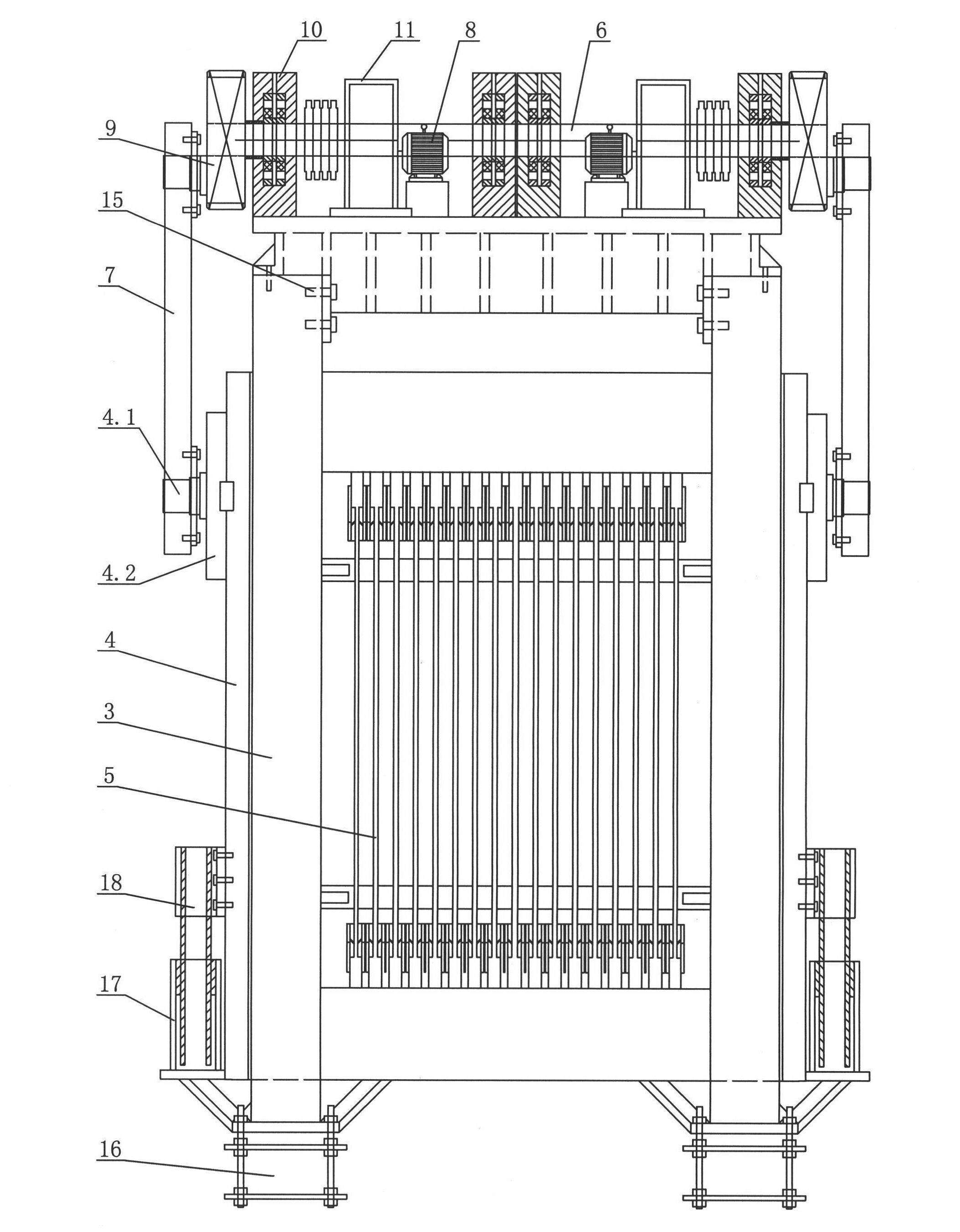

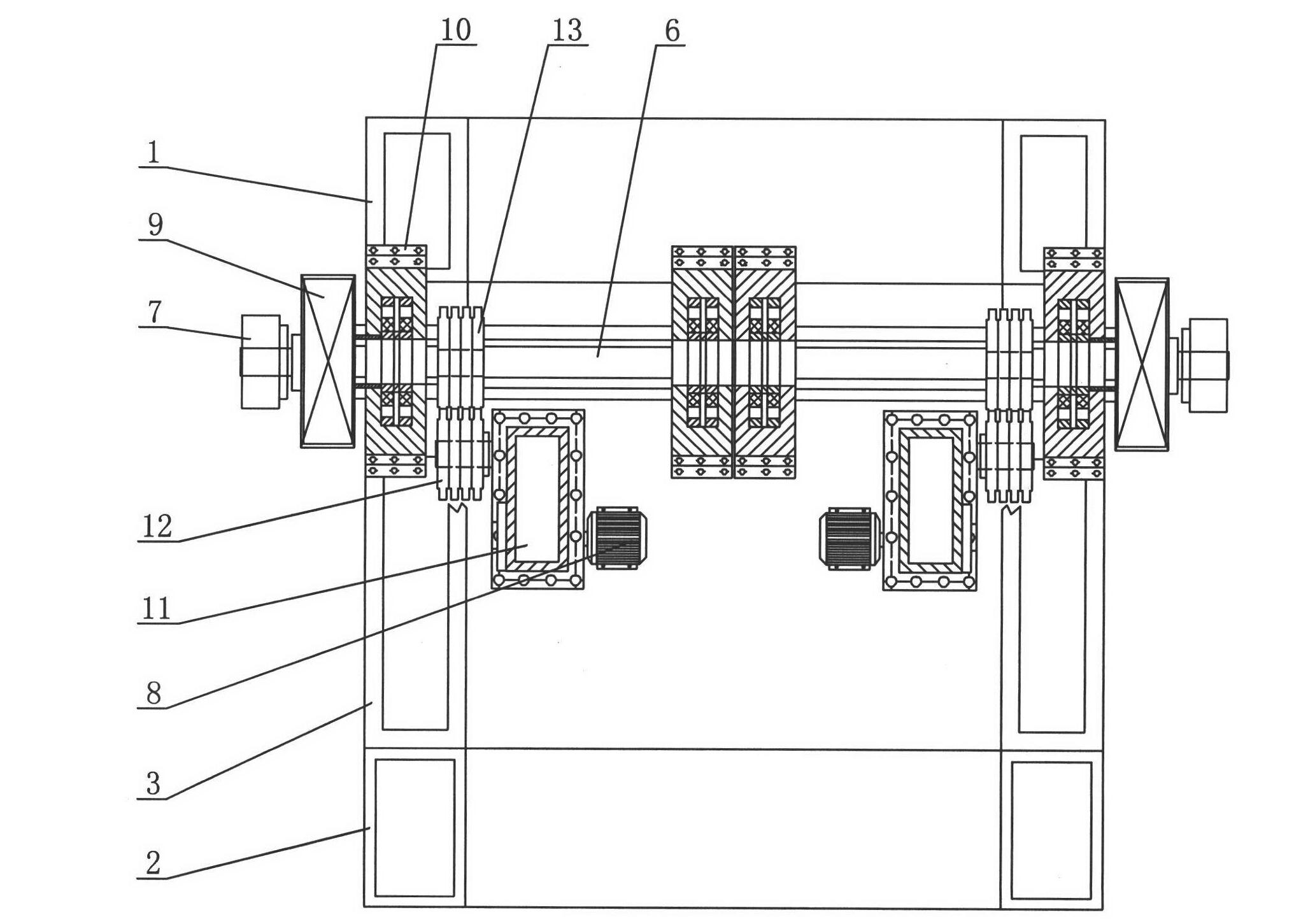

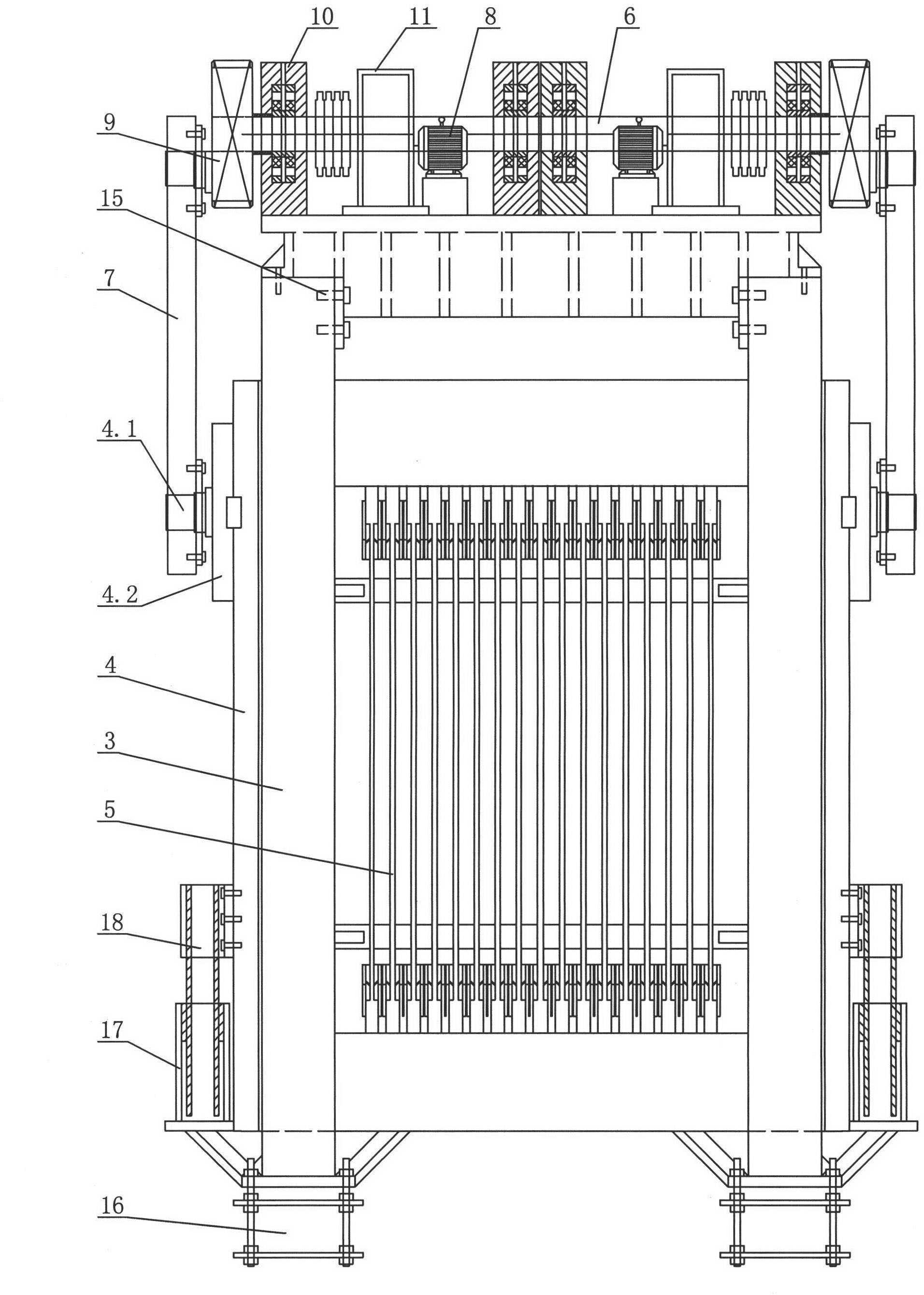

[0018] See Figure 1-Figure 2 , The vertical guiding structure of the saw frame of the stone sawing machine includes a top frame 3 arranged between the front column 1 and the rear column 2. The saw frame 4 is located below the top frame 3, and the saw frame 4 is provided with several saw blades 5, The top of the top frame 3 is provided with a transmission mechanism that can drive the saw frame 4 to move up and down. The lower parts of both sides of the saw frame 4 are provided with vertical guide mechanisms for guiding and buffering the up and down movement.

[0019] The vertical guide mechanism includes a piston seat 17 and a piston rod 18. The piston seat 17 is fixed on the bottom surface. One end of the piston rod 18 is fixed on both sides of the saw frame 4, and the other end goes deep into the piston seat 17 to slide up and down. The piston seat 17 can be a pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com