Production method of high-resistivity titanium dioxide

A high resistivity and production method technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low resistivity of titanium dioxide and cannot be widely used in the chemical fiber industry, and achieve simple and feasible production methods Strong, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation of titanium liquid

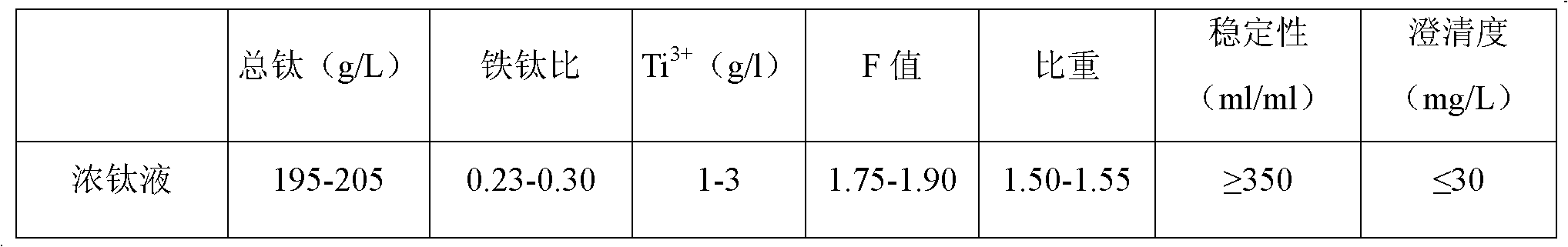

[0020] Titanium slag and titanium ore were reacted with sulfuric acid to obtain titanium solution, and the titanium solution was prepared with water to meet the hydrolysis requirements of concentrated titanium solution. The specific indicators of the concentrated titanium solution are shown in Table 1:

[0021] Table 1 Indicators of concentrated titanium solution

[0022]

[0023] Note: For the stability (ml / ml) in the table, the preceding "ml" represents the amount of distilled water, and the following "ml" represents 1ml of concentrated titanium solution.

[0024] Hydrolysis of B titanium solution

[0025] The hydrolysis process of the present invention is consistent with the conventional normal-pressure hydrolysis with external seed crystals, that is, after preheating the titanium solution → preparing the seed crystals → hydrolyzing, metatitanic acid can be obtained, and the particle size is D50 (D represents the diameter of the...

Embodiment 1

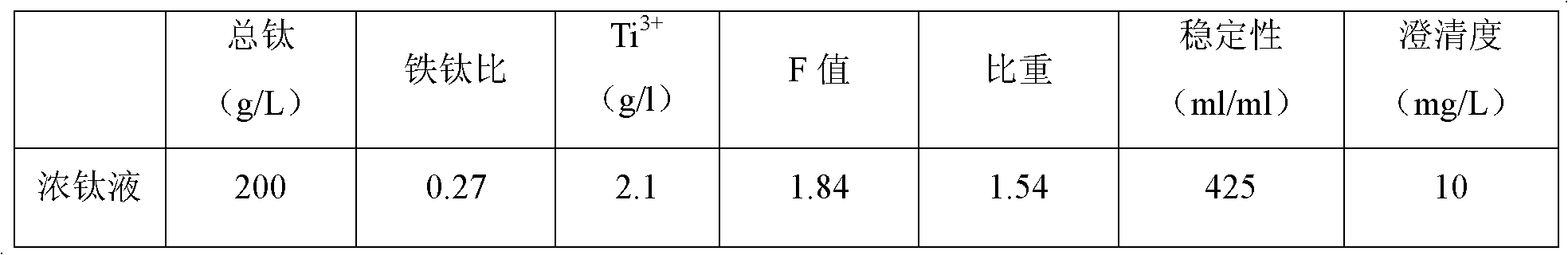

[0039] (1) The indicators of concentrated titanium solution are shown in Table 2;

[0040] Table 2 Indicators of concentrated titanium solution

[0041]

[0042] (2) The hydrolysis process is consistent with the existing external seed crystal hydrolysis at normal pressure, that is, the metatitanic acid can be obtained after preheating the titanium solution → preparing the seed crystal → hydrolyzing, and the particle size D50 is: 1.51 μm;

[0043] (3) Put the rinsed slurry into a salt treatment pot, add shallow desalted water to adjust the concentration of metatitanic acid slurry to 328g / l;

[0044] (4) After the slurry was stirred for 30min, potassium hydroxide was added, and the addition of potassium hydroxide was 0.46wt% of the titanium dioxide content (based on the titanium dioxide content in metatitanic acid), stirred for 30min, and then added 0.28wt% of the titanium dioxide content phosphoric acid, stirred for 30min, and fed to the storage tank in front of the kiln; ...

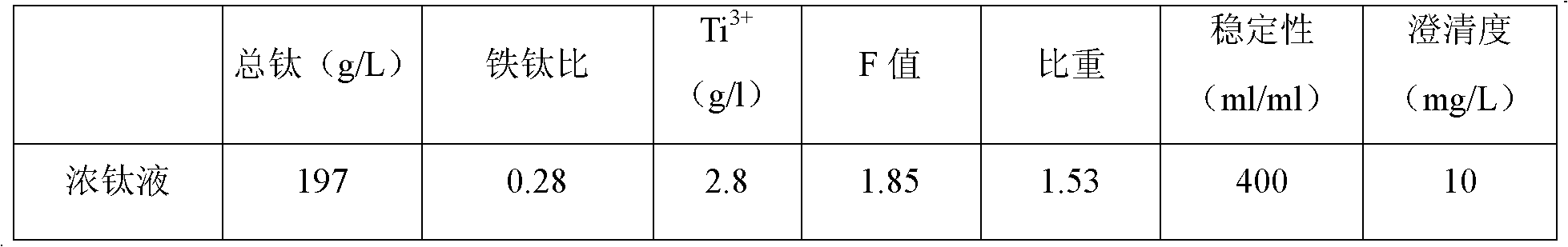

Embodiment 2

[0049] Except that the add-on of potassium hydroxide in step (4) is different from that in Example 1, other steps are all the same as in Example 1, and the add-on of potassium hydroxide in step (4) is 0.41wt% of titanium dioxide content; Gained product performance As shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com