Power transmission module with self-locking mechanism

A technology of power transmission and self-locking mechanism, applied in mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problems of energy waste and safety, heavy objects falling, loss of power source of power transmission modules, etc., to achieve optimal control and stability performance, reducing the risk of burnout, saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

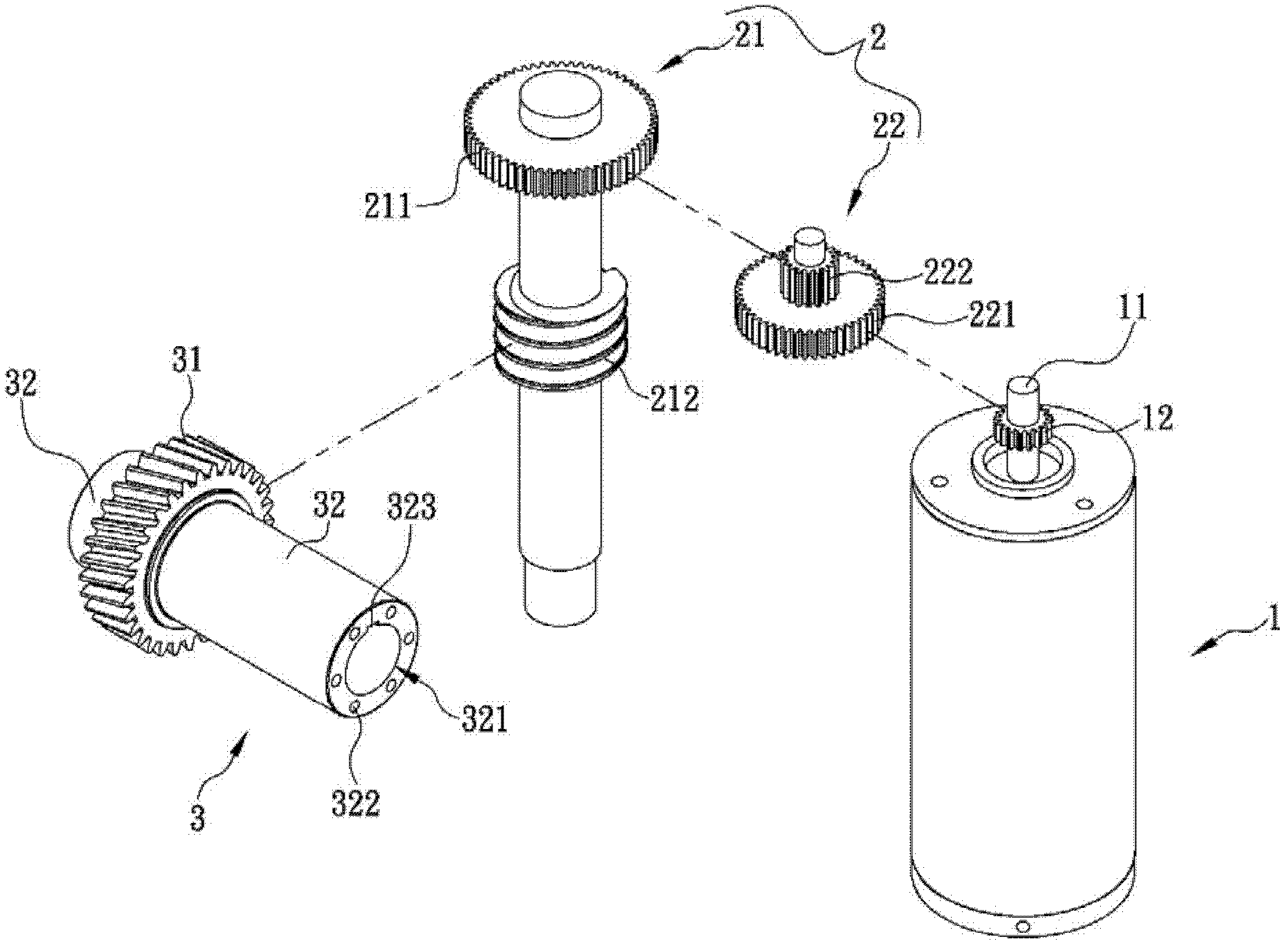

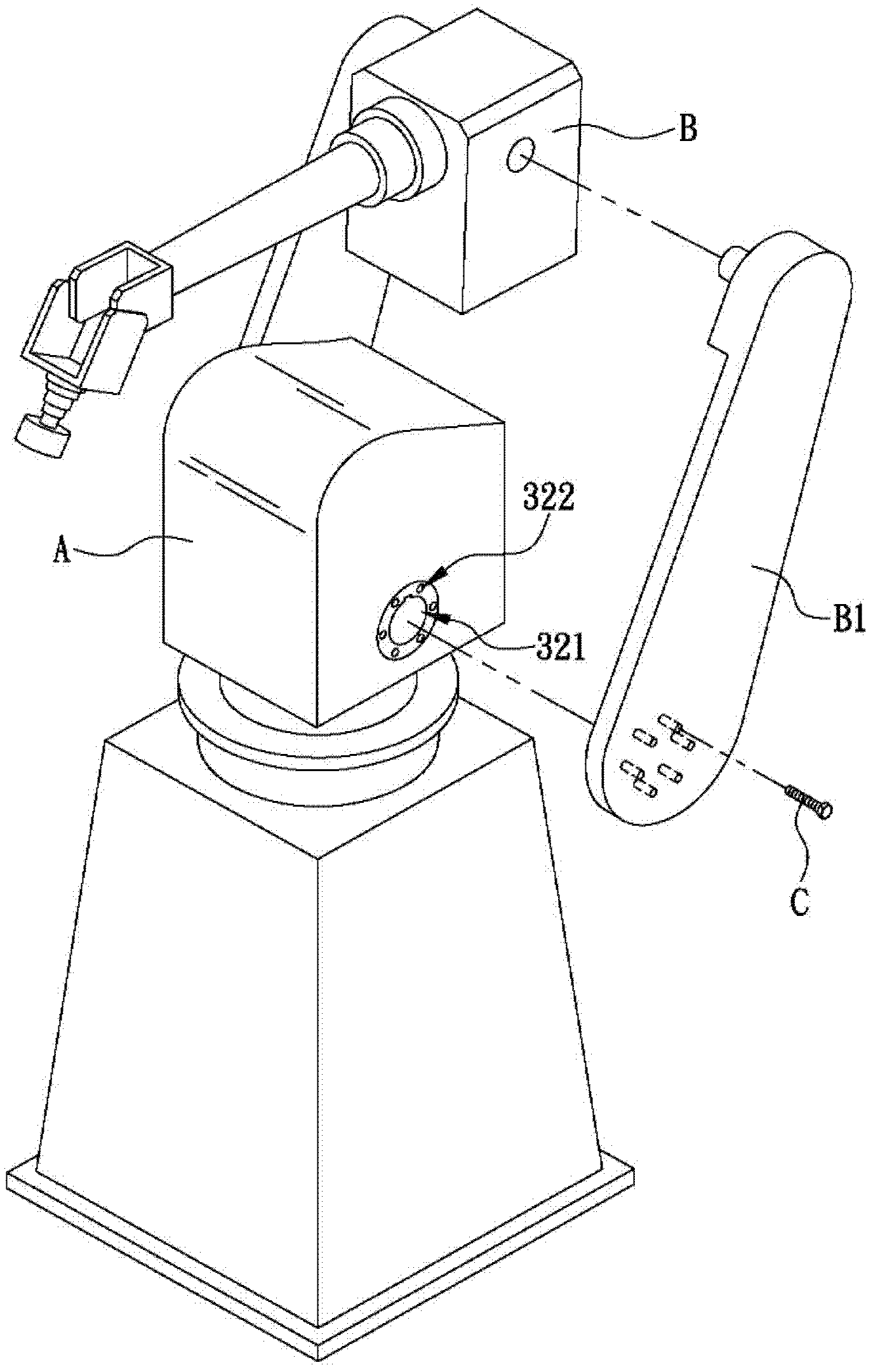

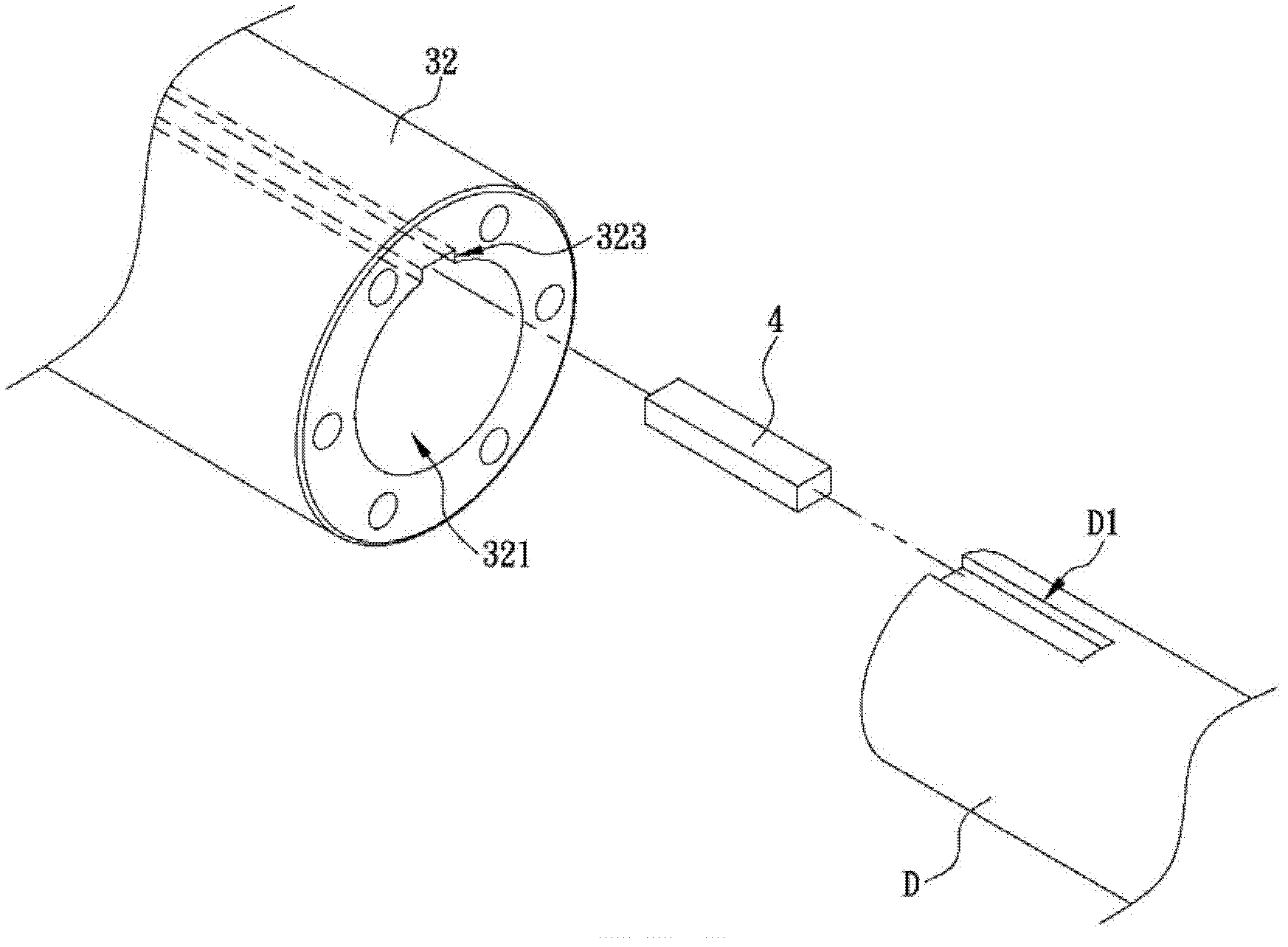

[0046] Such as figure 1As shown, the power transmission module with self-locking mechanism of the present invention includes an actuator 1, a reduction mechanism 2 and a driven shaft 3, wherein the actuator 1 can be a DC motor, an AC induction motor, an AC synchronous motor, a switch type Reluctance motors or stepping motors, etc., during production, manufacturers can choose motors with different characteristics according to their needs, or design servo motors with other feedback devices (such as: photoelectric encoders or resolvers, etc.). A driving shaft 11 of the actuator 1 is provided with a coaxially rotating driving gear 12, and the driving shaft 11 can rotate together with the driving gear 12; in this embodiment, the reduction mechanism 2 includes a transmission shaft 21 and a Reduction gear 22, drive shaft 21 is provided with a driven gear 211 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com