Bisection moving rocker arm mechanism driven by worm wheel and worm

A technology of worm gear and rocker mechanism, which is applied in gear transmission, mechanical equipment, transmission, etc., can solve the problems of inability to meet functional requirements, inability to achieve self-locking function, and insufficiently compact structure, and achieve low noise and simple structure. , the effect of enhancing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

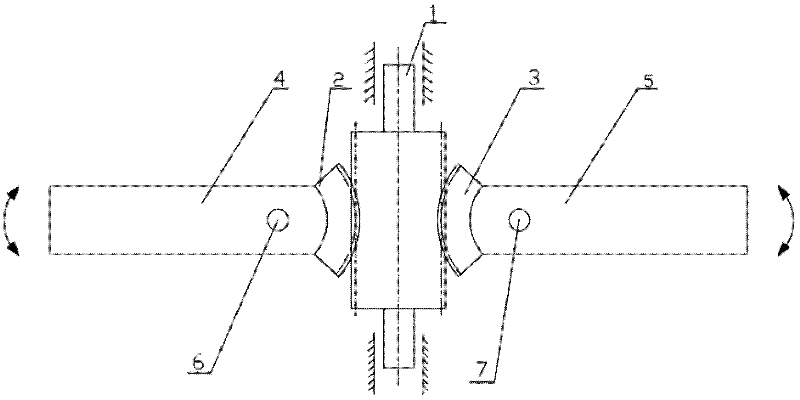

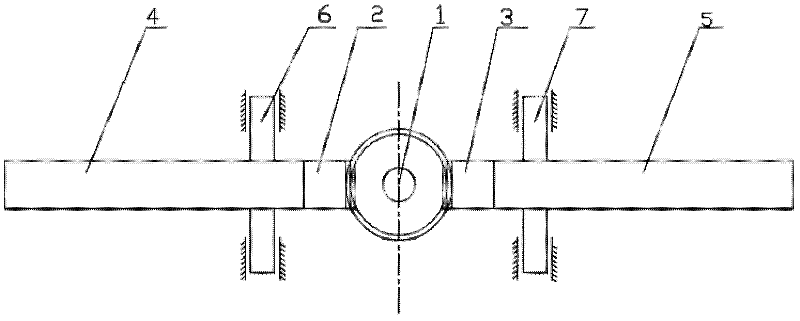

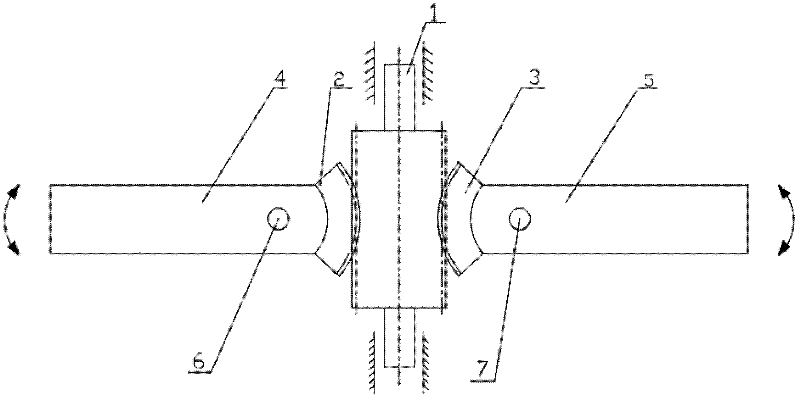

[0031] See figure 1 , figure 2 , the present invention is a worm gear driven bisecting motion rocker mechanism, which is composed of a worm 1, a left worm wheel 2, a right worm wheel 3, a left rocker arm 4, a right rocker arm 5, a left shaft 6 and a right shaft 7, among them The position connection relationship among them is: the worm 1 meshes with the left worm gear 2 and the right worm gear 3 respectively; the left worm gear 2 and the right worm gear 3 are rigidly connected with the left rocker arm 4 and the right rocker arm 5 respectively; The centerlines of the left and right turbines coincide with the centerlines of the left turbine 2 and the right turbine 3 respectively; the left shaft 6 and the right shaft 7 are fixedly connected to the left rocker arm 4 and the right rocker arm 5 respectively;

[0032] The worm 1 is made of a cylindrical stepped shaft with an axial modulus of 3.15, an axial head number of 1, and a lead angle of 15°;

[0033] The left turbine 2 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com