Clearance seal structure capable of sealing liquid and solid phases

A technology of sealing structure and gap structure, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as difficult sealing, achieve the effect of avoiding wear, improving sealing stability and working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

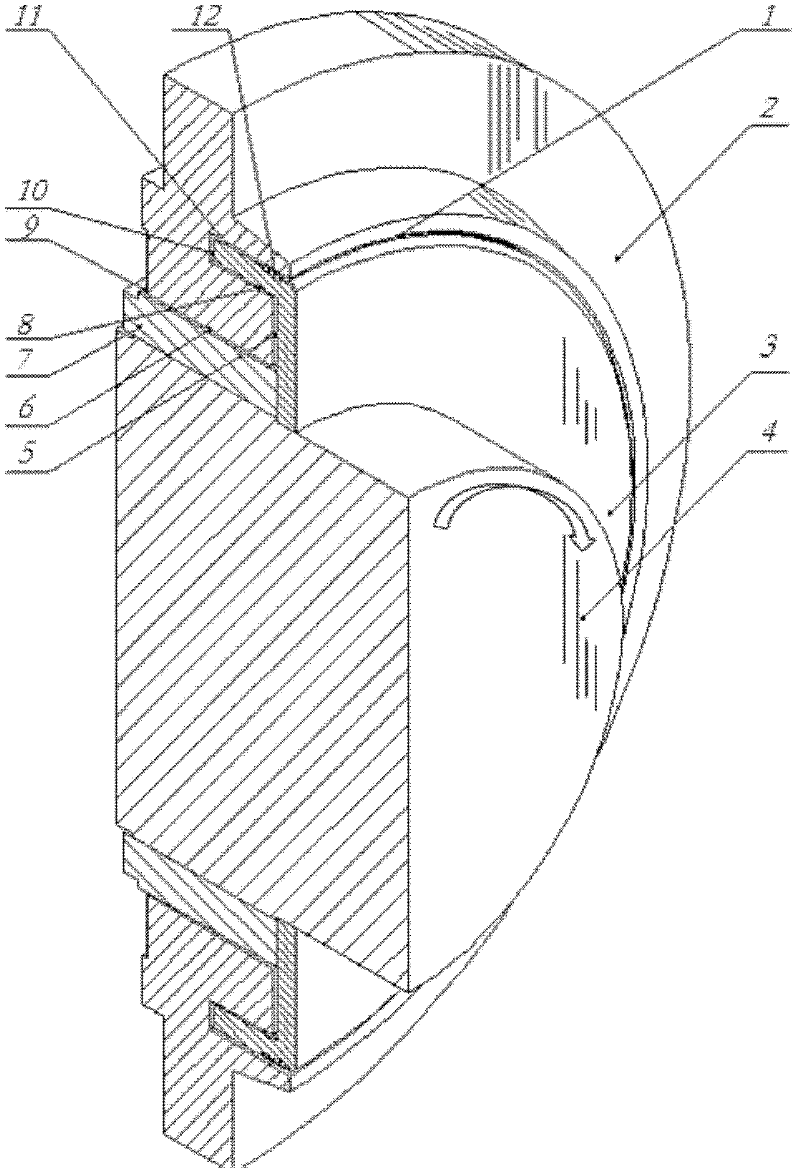

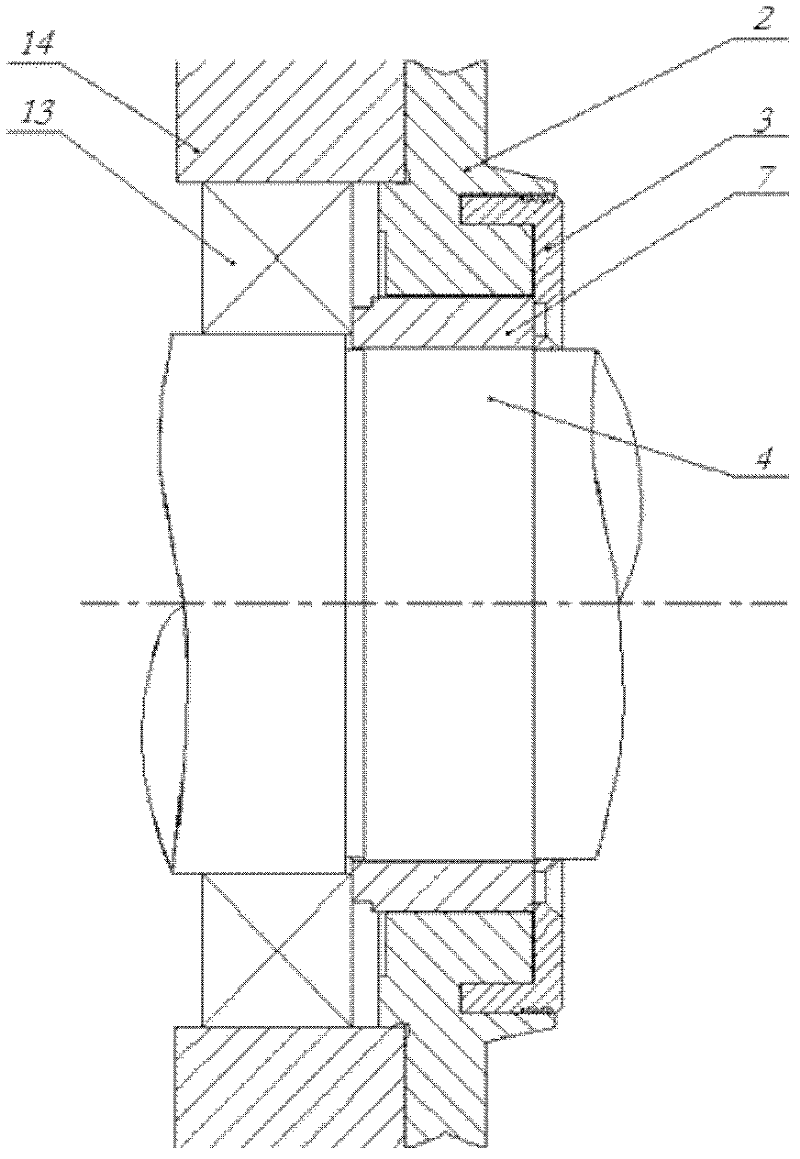

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] see figure 2 , the sealable liquid-solid two-phase gap sealing structure of the present invention is a gap structure formed by assembling the bearing end cover 3, the bearing seat 2 and the shaft sleeve 7; the shaft sleeve 7 and the bearing end cover 3 rotate with the main shaft 4 The shaft sleeve 7 is installed on the main shaft 4 through interference fit; there is a bolt hole for bolt connection between the bearing end cover 3 and the shaft sleeve 7, and the bearing end cover 3 is installed on the shaft sleeve 7 through bolts, and rotates with the main shaft 4 sports. The bearing seat 2 is installed on the fixed wall surface 14, and the bearing seat 2 is provided with bolt holes, and is fixedly installed on the wall surface 14 by bolts. The gap structure formed by the assembly of the bearing end cover 3, the bearing seat 2 and the shaft sleeve 7 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com