Electric greasing device capable of controlling grease quantity

A fat volume and electric technology, which is applied in the field of mechanical engineering, can solve the problem that the speed of grease injection cannot be adjusted, and achieve the effects of stable force transmission, saving human resources, and increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

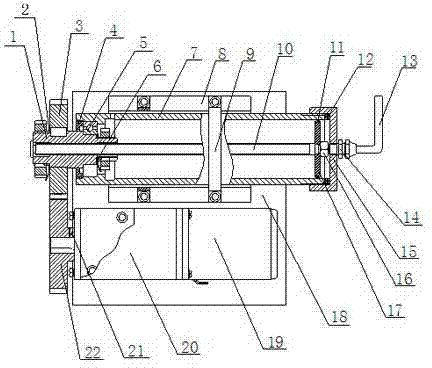

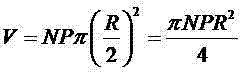

[0017] As shown in the figure, an electric grease controllable greasing device includes a hydraulic cylinder 7, a fixing member 9, a support frame 8, a sealing cover 4, a piston 17, an end cover 15 and a base 18, and the internal design of the hydraulic cylinder 7 is There is a piston 17, the left end is provided with a sealing cover 4, the right end is provided with a felt sealing ring 12 and an end cover 15 in turn, the hydraulic cylinder 7 is arranged on the support frame 8, and is connected with the base 18 through the fixing piece 9; the fat outlet pipe 13 passes through the pipe The joint 14 is connected with the end cover 15, and is also provided with a transmission main gear 22, a transmission sub-gear 3, a sleeve 1, a screw 10, a reducer (20) and a servo motor (19), wherein the right end of the screw 10 passes through a fixing nut 16 Connected with the piston 17, the left end of the screw rod 10 is set in the sleeve 1 through threads; the right end of the sleeve 1 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com