Liquid storage device of plate-type propellant management apparatus

A technology of plate propellant and management device, which is applied in the field of accumulator, can solve the problems of high requirements on satellite control ability, poor ability to withstand mechanical environment, and difficult to connect the deflector, and achieves light weight, strong adaptability, structure and so on. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

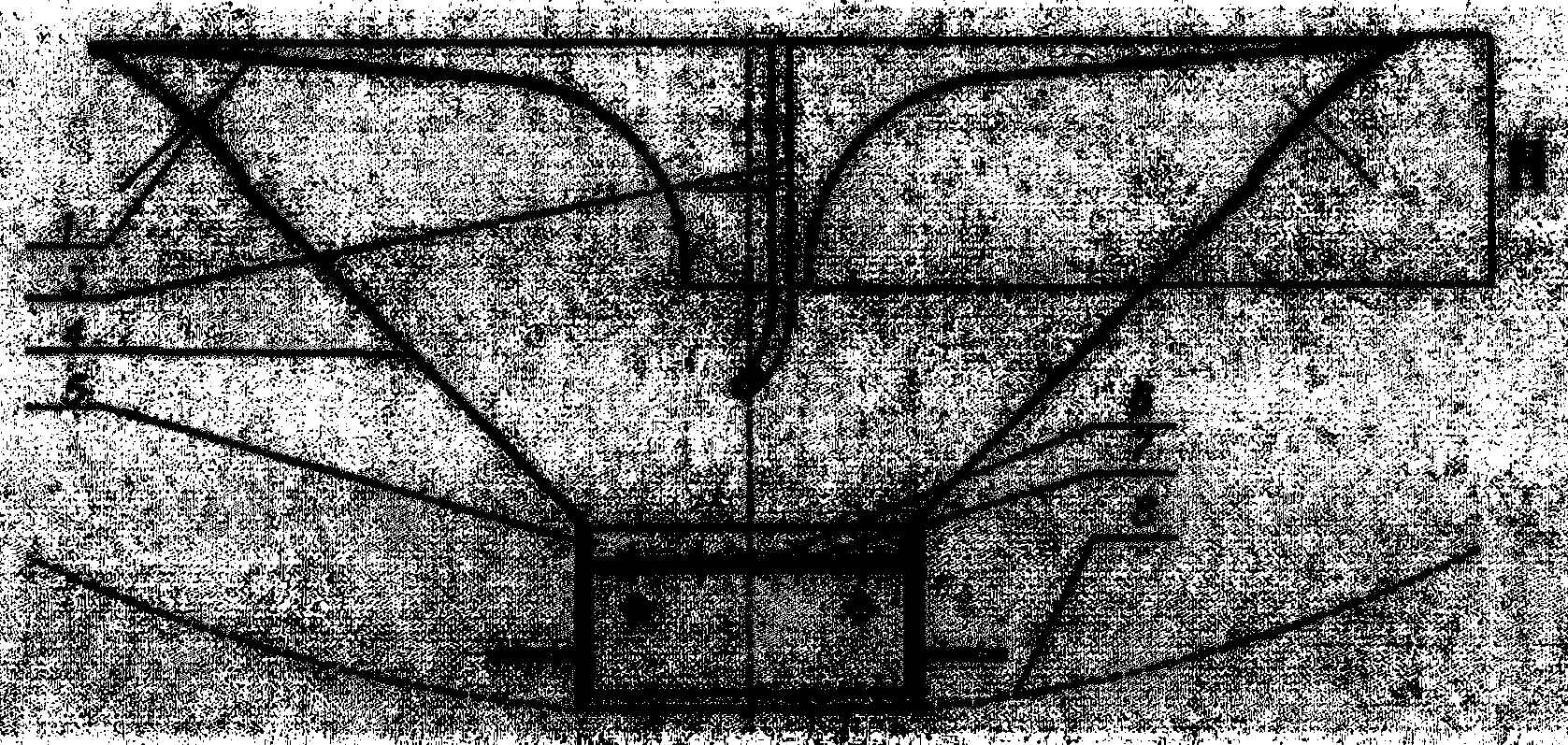

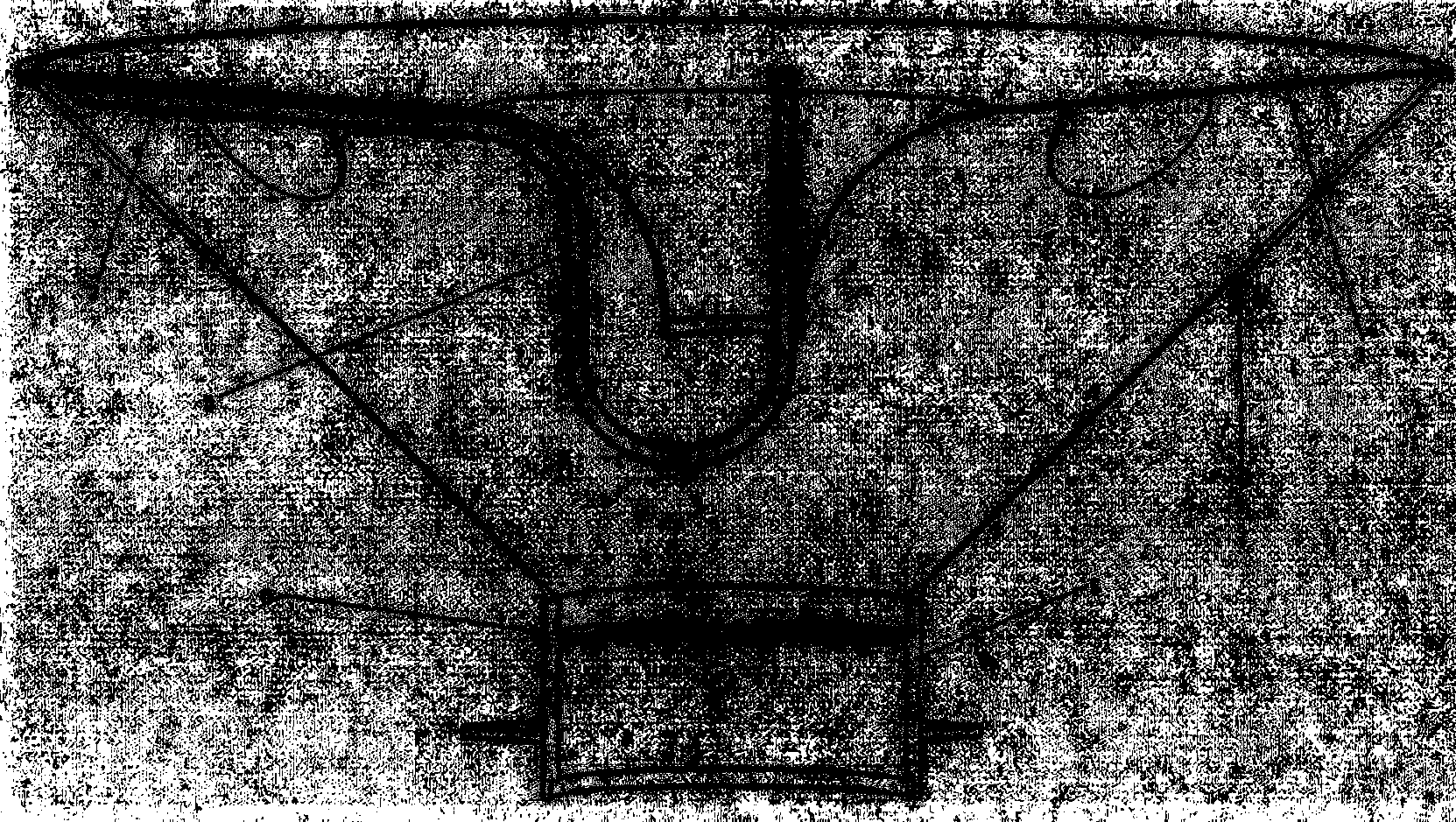

[0031] Such as Figure 1~4 As shown, the accumulator of the plate-type propellant management device includes the following components: accumulator inner cone 1, accumulator outer cone 4, accumulator base 5, air guide tube 3, two air guide tube fixing blocks 2, two Liquid accumulator mesh support pressure plate 6, liquid accumulator mesh 7. The inner cone 1 of the accumulator is electron beam welded to the outer cone 4 of the accumulator; the outer cone 4 of the accumulator is electron beam welded to the base 5 of the accumulator.

[0032] The accumulator adopts two complete conical structures inside and outside, that is, the conical structure composed of the inner cone 1 of the accumulator and the outer cone 4 of the accumulator. The angled area between the outer cones of the accumulator and the angled area between the outer cone 4 of the accumulator and the inner wall surface 8 of the tank shell are used to store sufficient propellant, and the air guide tube is used The gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com