Spring-ring type inserting hole and inserting needle thereof

A spring coil and pin technology, which is applied to contact parts, electrical components, coupling devices, etc., can solve the problems of long plug-in sections of high-current connectors, difficult to meet high-current conditions, and large size, and achieves a solution to plug-in The effect of segment length, high practical value and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

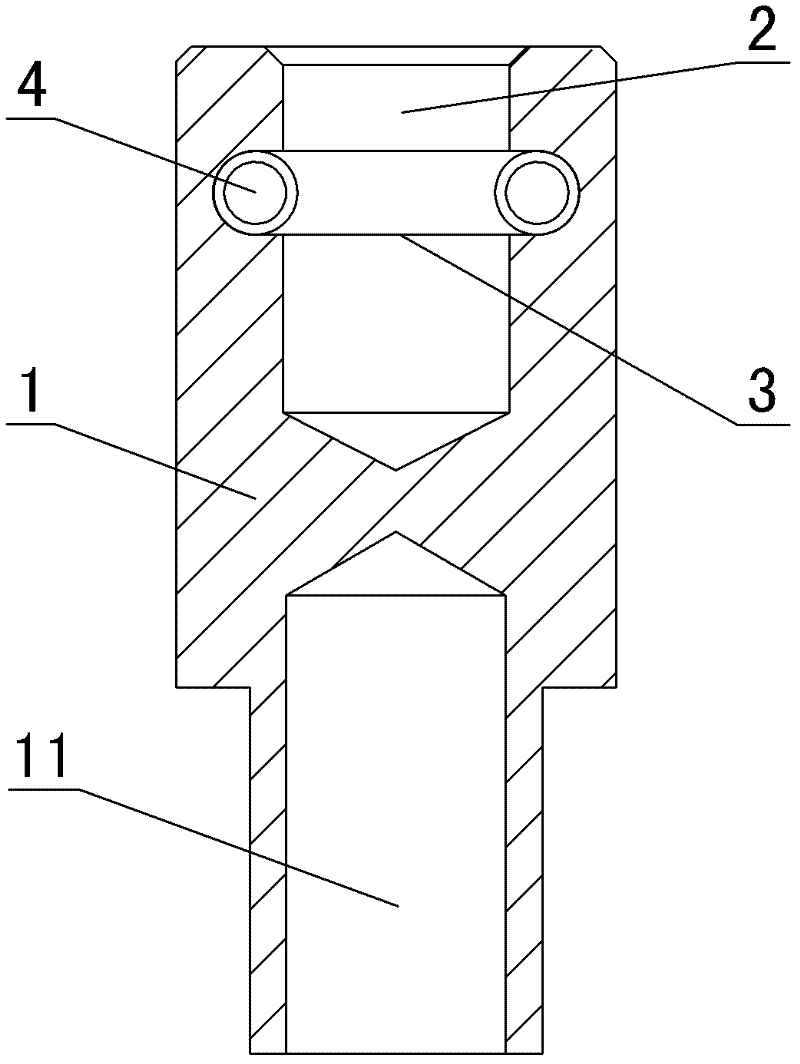

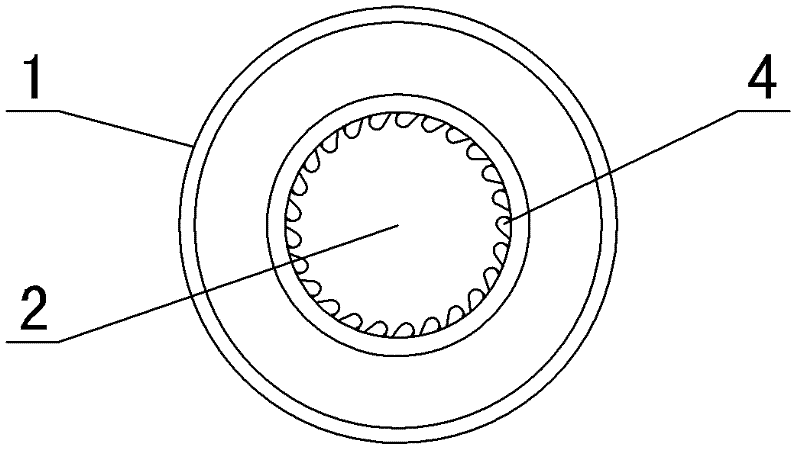

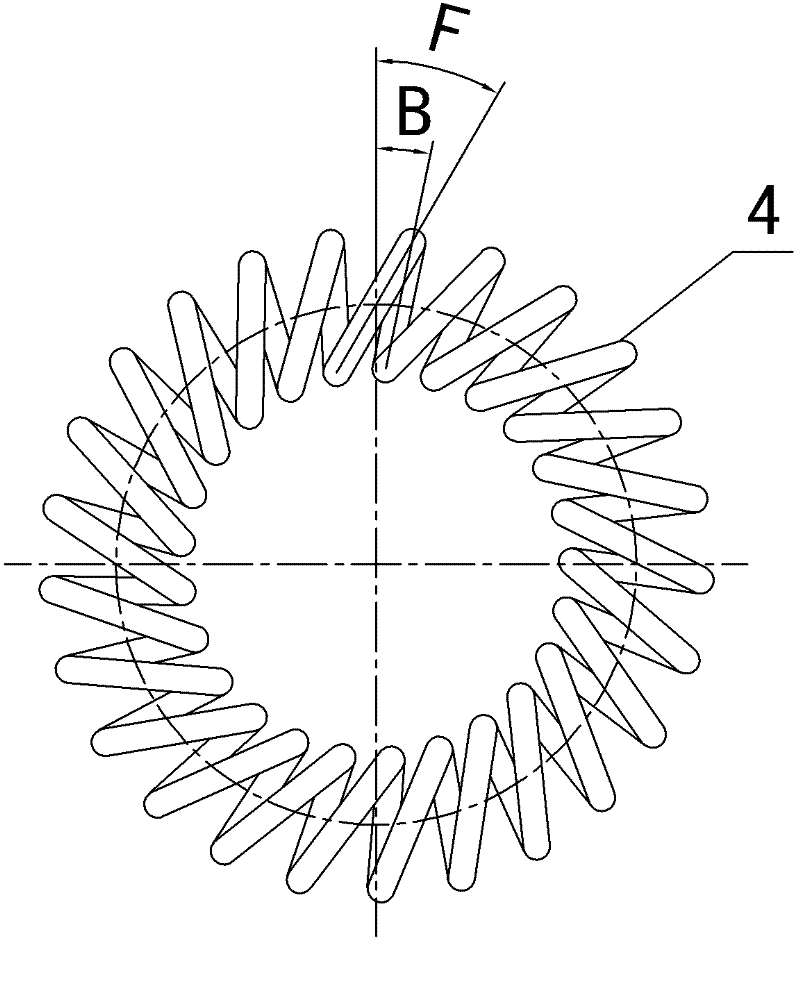

[0029] in such as figure 1In the shown embodiment, a spring coil socket includes a socket body 1 provided with a circular pin hole 2 and a wiring hole 11, and a U-shaped cross section is provided on the inner wall of the pin hole. Shaped annular groove 3, the circular groove is provided with a helical coil 4 with a circular cross section, the inner diameter of the helical coil is smaller than the aperture of the pin hole (see figure 2 ), the depth of the annular groove is 60% of the radial outer diameter of the helical spring constituting the helical spring coil. The height of the spring ring is consistent with the width of the annular groove. The helical spring 5 that constitutes the helical spring ring is an oblique spring, and the helix angle of the helical spring ring changes periodically. The forward inclination angle F between the shaft sections is 30 degrees, and the back inclination angle B between the projection line of the spring line on the other side on the horiz...

Embodiment 2

[0032] in such as Figure 5 In the shown embodiment 2, the cross-section of the helical spring coil is elliptical, and the major axis of the ellipse is parallel to the axis of the pin hole. The spring ring is suitable, and the depth of the annular groove is 70% of the outer diameter of the helical spring constituting the helical spring ring in the radial direction of the helical spring ring, and all the other are the same as in embodiment 1.

Embodiment 3

[0034] in such as Image 6 In the shown embodiment 3, two annular grooves are provided on the inner wall of the pin insertion hole, and a helical spring coil with a circular cross section is provided in the annular groove, and the helical spring coils in the two annular grooves have opposite directions of rotation.

[0035] The pins that are compatible with the spring coil jack of this embodiment are as follows: Figure 10 As shown, the pin head is provided with two arc-shaped grooves surrounding the outer peripheral surface of the pin head. The position of the arc-shaped grooves matches the annular groove in the pin hole of Embodiment 3, and the rest is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com