Power distribution cabinet system

A technology for power distribution cabinets and electrical systems, applied in the field of power distribution cabinet systems, can solve problems such as hidden safety hazards, decreased insulation performance, insufficient electrical clearance, etc., and achieve the effect of removing hidden dangers of composite insulation, reasonable and perfect layout, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

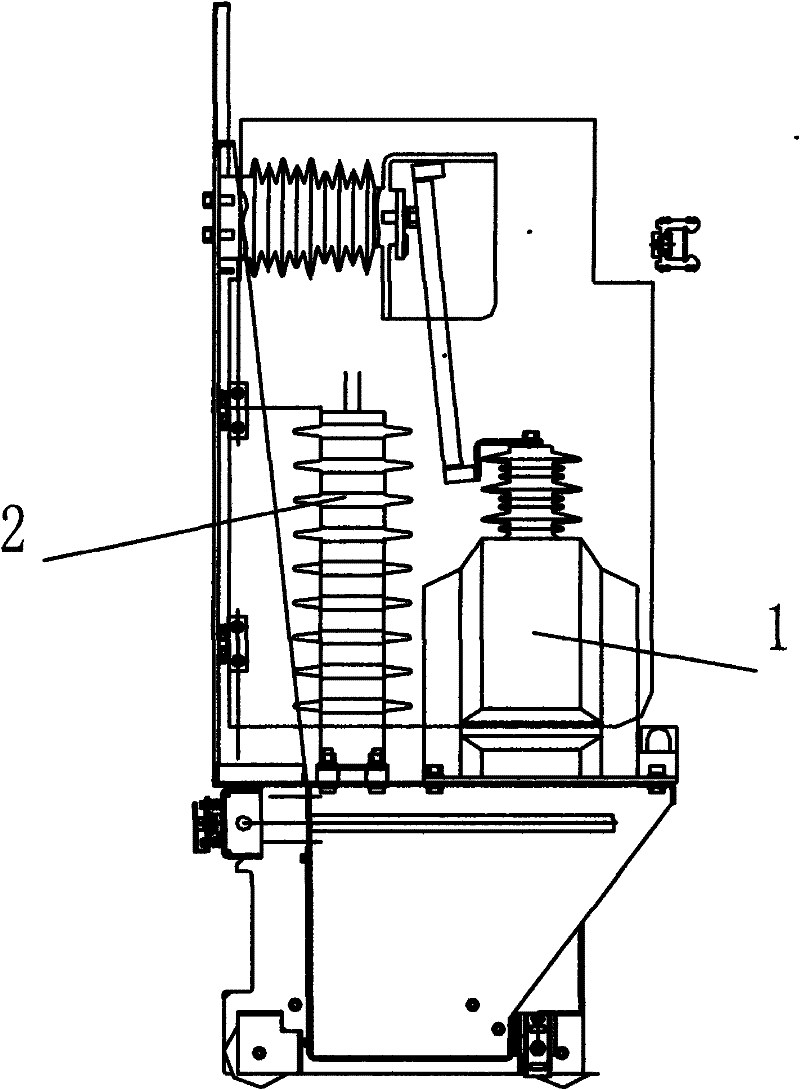

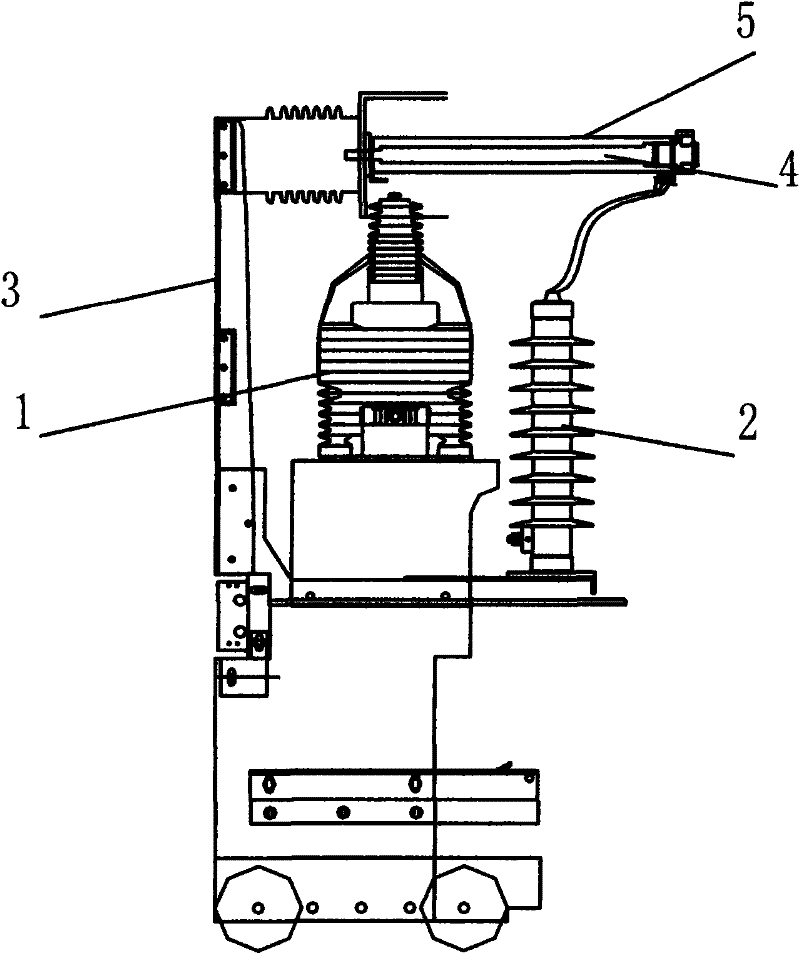

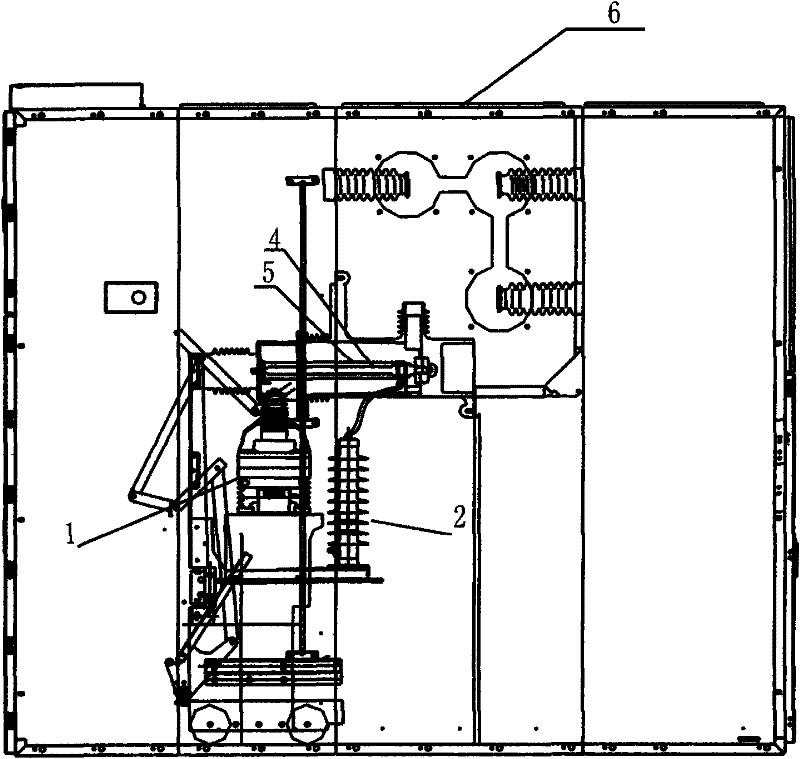

[0012] A power distribution cabinet system, comprising a cabinet body 6, the cabinet body 6 is provided with a primary electrical system, a switch cabinet, a contact box and a support plate 3 on the side of the PT vehicle, and the upper end of the support plate 3 is connected to the The contact arm 5 is connected, and a fuse 4 is arranged in the contact arm 5; the PT car is divided into upper and lower layers, the upper surface of which is connected with the voltage transformer 1, and the lower surface is connected with the lightning arrester 2; the lightning arrester 2 The upper end is connected with the external lead of the copper bar arranged at the port of the fuse 4 through a conductive connector; the contact arm 5 is made of insulating material.

[0013] The present invention considers the overall space, the circuit breaker room and the cable room sealing plate arranged in the cabinet body 6 are moved backward, and the primary bushing is moved up to expand the space of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com