Dual-motor switching control method for wind generating set

A technology for wind turbines and wind turbines, applied in the direction of single-network parallel feed arrangement, etc., can solve the problems of wind rotor efficiency reduction, blade stall, efficiency decline, etc., to improve power generation efficiency, reliable switching control, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below with reference to the accompanying drawings and specific embodiments.

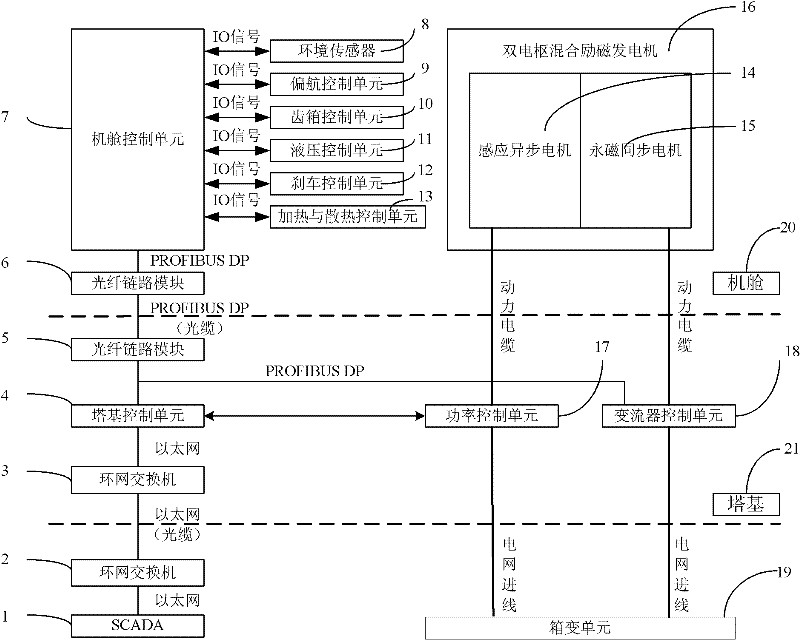

[0028] figure 1 Shown is the structure diagram of the control system of the wind power generating set applying the present invention.

[0029]The dual-armature hybrid excitation wind turbine control system is mainly composed of a nacelle control subsystem 20 and a tower base control subsystem 21, and the communication between the nacelle control subsystem 20 and the tower base control subsystem 21 is carried out by means of PROFIBUS DP. The cabin control subsystem 20 mainly includes a cabin control unit 7, an environment sensor 8, a yaw control unit 9, a gearbox control unit 10, a hydraulic control unit 11, a brake control unit 12, a heating and cooling control unit 13, and a dual armature Hybrid excitation generator; tower base control subsystem 21 mainly includes tower base control unit 4 , power control unit 17 and converter control unit 18 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com