Manufacturing method of back drill holes on PCB (Printed Circuit Board)

A technology of PCB board and manufacturing method, which is applied in the direction of multi-layer circuit manufacturing, electrical connection formation of printed components, etc., can solve the problem of affecting the quality of PCB board and the integrity of signal transmission of electronic products, the length of residual useless copper 05 is long, and it cannot be very fast. To meet customer requirements and other issues, to achieve the effect of high-density wiring, reduce back-drilling aperture and hole pitch line design, and improve the utilization rate of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

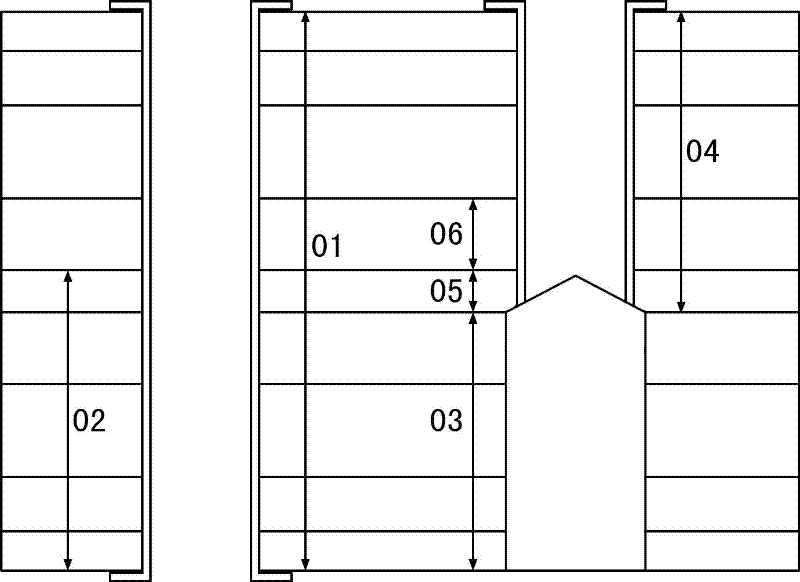

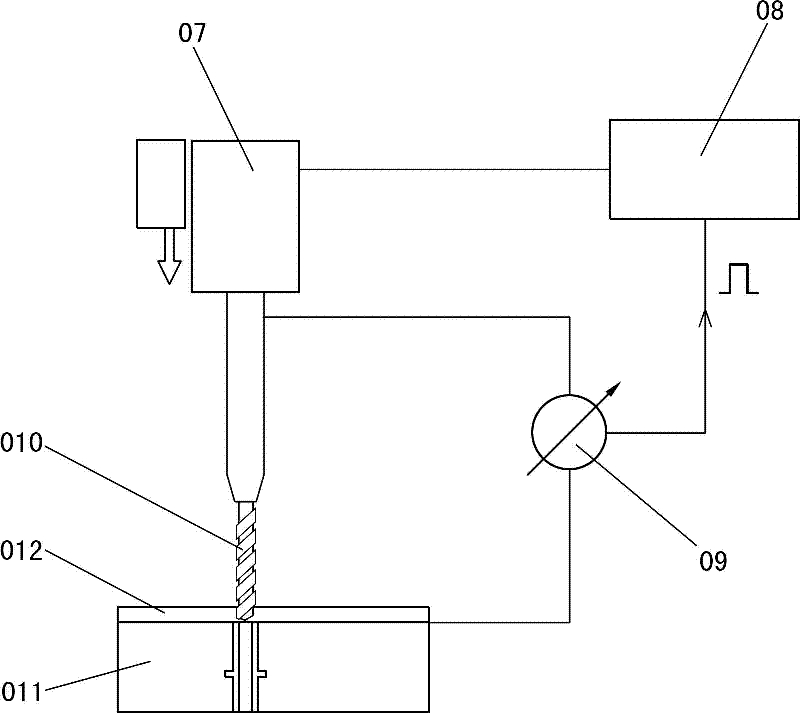

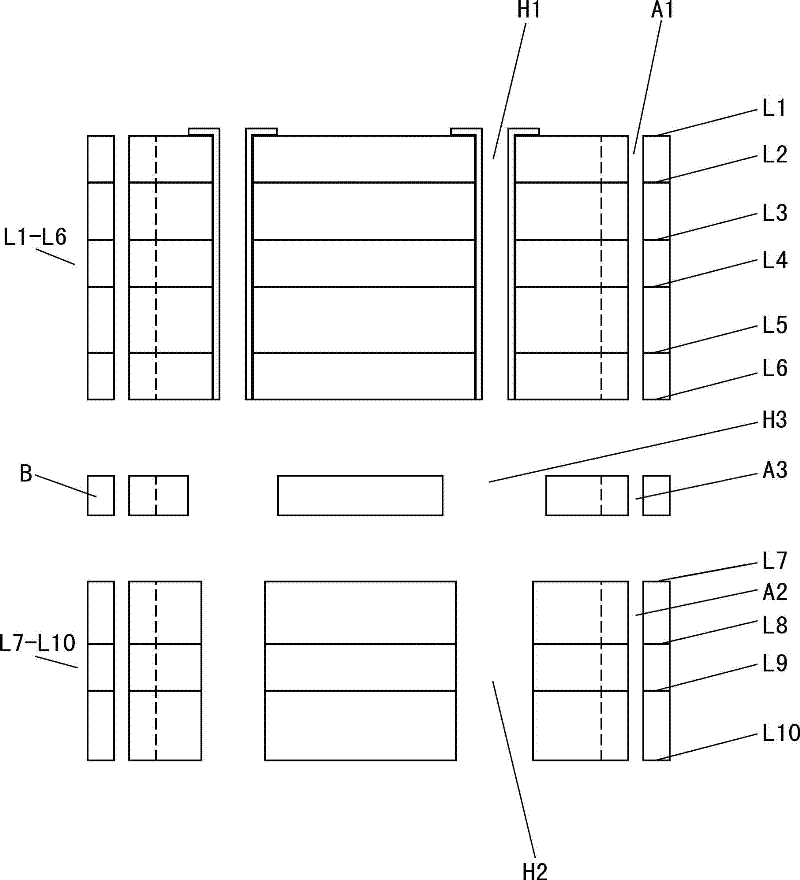

[0030] Such as image 3 , Figure 4 and Figure 5 As shown, the PCB board in this preferred embodiment is a ten-layer board, and the manufacturing method of back-drilling holes on PCB boards with other layers can refer to this preferred embodiment for manufacturing.

[0031] (1) According to the level distribution of metallized holes and non-metallized holes on the PCB board to be produced, the layers L1, L2, L3, L4, L5, L6, L7, L8, L9 of the PCB board will be formed , L10 is divided into each layer L1, L2, L3, L4, L5, L6 that constitutes the metallized hole layer and each layer L7, L8, L9, L10 that constitutes the non-metallized hole layer;

[0032] (2) Each layer L1, L2, L3, L4, L5, and L6 constituting the metallized hole layer is sequentially transferred and pressed to form the metallized hole layer L1-L6, such as image 3 shown; then, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com