Cotton picker unit drive with controllable spindle speed to drum speed ratio and belt drive

A technology of driving device and spindle picking drum, which is applied in harvesting machines, agricultural machinery and implements, agriculture, etc., and can solve problems such as noisy and expensive systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

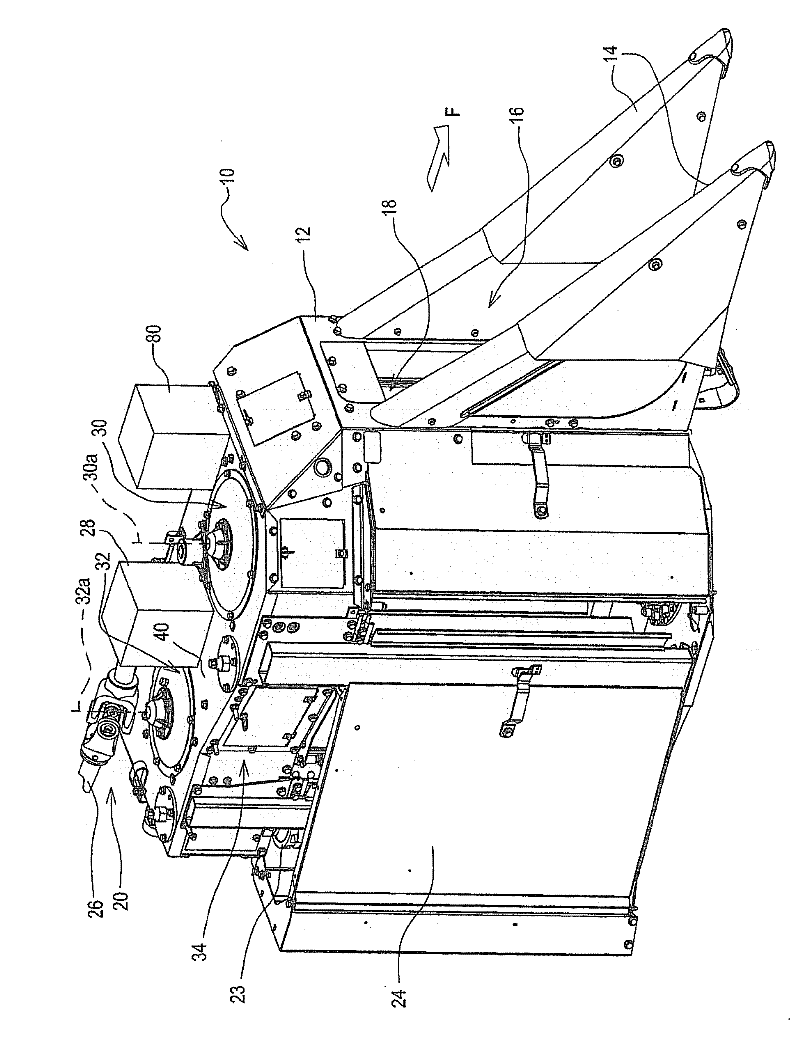

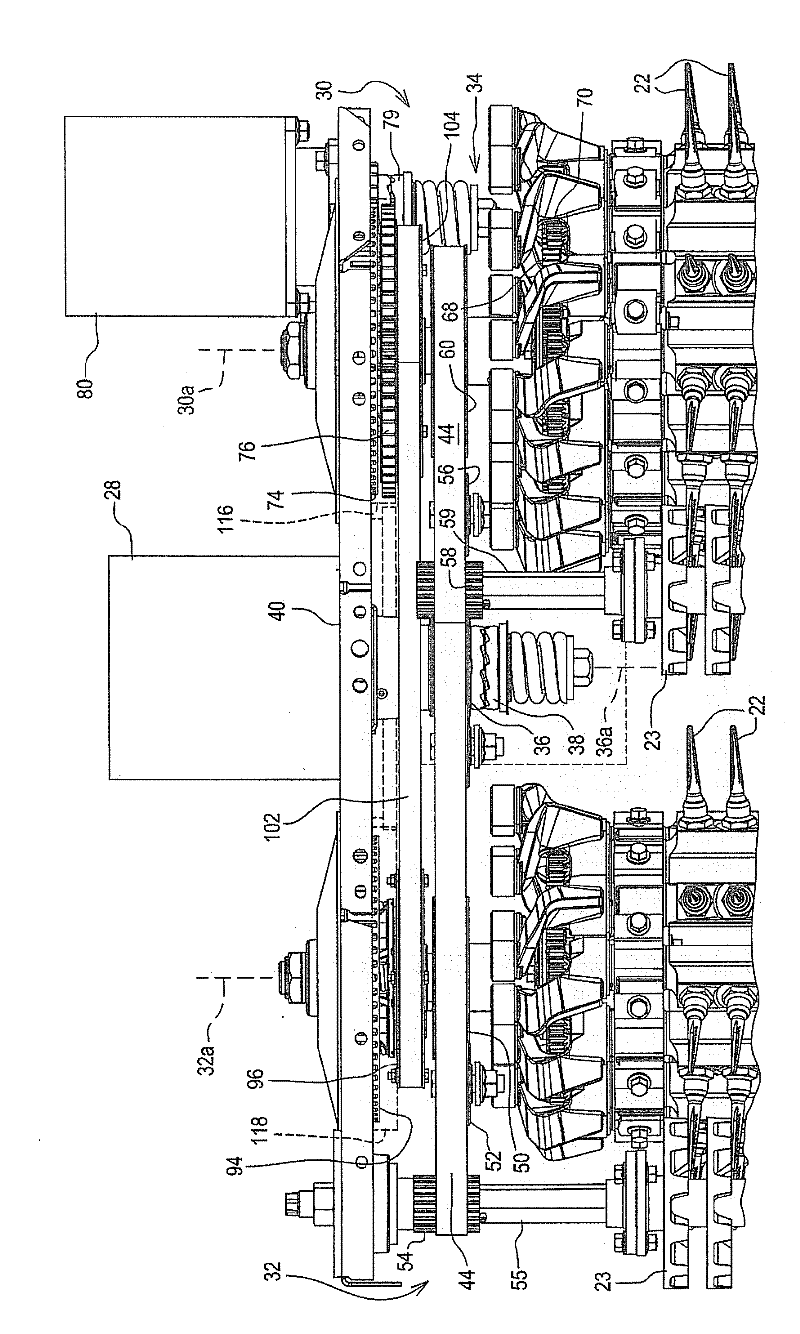

[0011] refer to figure 1 , which shows a cotton harvester row unit 10 having a row unit housing 12 and a crop lifter 14 supported for forward movement F on the ground for receiving a row of cotton plants located in a cotton row receiving area 16 . Picking and doffering structure 18 supported in housing 12 is powered by drive structure 20 . Spinning Spindle 22 ( image 3 ) removes cotton from the cotton plants entering the cotton row receiving area 16. The removed cotton is unwound from the spindles 22 by the doffer 23 and is transported back into the gate structure 24 towards a cotton receiving device (not shown). Except for the drive structure 20 described in detail below, the row unit 10 may be of a conventional structure, such as the type shown and described in the aforementioned US Patent No. 5,325,656. Other row cell configurations may also be used, and the present configuration is given as an example only to help describe the drive structure 20 embodiment.

[0012] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com