Scarf rope twisting and knot tying machine and rope twisting and knot tying method

A knotter and scarf technology, which is applied to scarves, scarves, head scarves and other directions, can solve the problems of a large number of labors, ununified and time-consuming rope knotting work, saving production and processing time, shortening product delivery, The effect of ideal appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

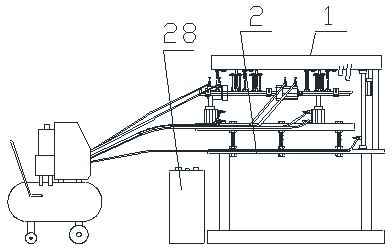

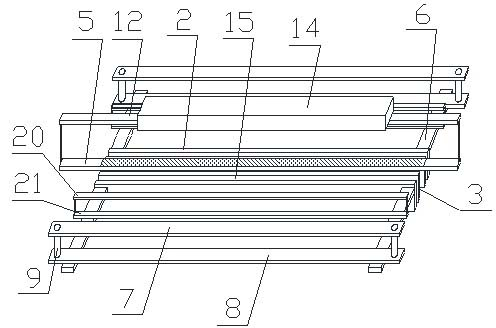

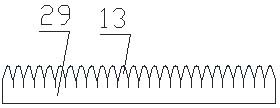

[0017] Embodiment 1: with reference to attached Figure 1-8 , a scarf rubbing rope knotting machine, which includes a frame 1, a positioning device, a rope rubbing device and a knotting machine, the frame 1 includes a bottom beam 2 and a middle beam, and a hook knife runs through the middle of the bottom beam 2 Groove 3, lifting arrangement type hook knife 4 is arranged in the hook knife groove 3 in the middle of the bottom beam 2, the lower washboard 5 is arranged on the bottom beam 2 of the frame 1, and the slideway 6 is arranged on the left and right sides of the bottom beam 2, and the The knotting machine is installed on the middle beam of the frame 1. The positioning device includes upper and lower pressure plates 7, 8 and slideways 6. The lower pressure plate 8 is arranged on the slideways 6 on both sides of the bottom beam, and is parallel to the bottom beam 2. The pressure plate 7 is arranged above the corresponding lower pressure plate through the lifting rod 9. The s...

Embodiment 2

[0018] Embodiment 2: with reference to attached figure 1 , 4And 5, a scarf rubbing rope knotting machine, the knotting machine includes a knotting head 16, a reel 17 and a crotch 18, the knotting head 16 is columnar, and is evenly arranged on the lifting beam 19, the upper and lower rubber The presser feet 20, 21 are arranged on the slideways 6 on both sides of the bottom beam 2. The upper and lower rubber presser feet 20, 21 can not only be used for positioning the rope-shaped tassels, but also because the rubber presser feet have certain elasticity, it is convenient to press the rope-shaped tassels. Twitching, the winding head 22 is fixed on the bottom of the knotting head 16, and the end side of the winding head 22 is provided with a protrusion 23, and the protrusion 23 can prevent the rope-shaped tassel wound on the winding head 22 from slipping, so that the knotting is successful. Efficiency improves greatly, and reel 17 is installed on the side of knotting head 16, and ...

Embodiment 3

[0019] Embodiment 3: On the basis of Embodiments 1 and 2, when rubbing the rope, place the two ends of the scarf on the lower pressing plate 8 of the frame 1, and manipulate the controller 28 to lower the upper pressing plate 7 to be in close contact with the corresponding lower pressing plate 8. Thereby the scarf is fixed and the reserved weft yarn is placed between the pressing plates on both sides of the frame, and then the lower pressing plate 8 is pushed back and forth to slide along the slideways 6 on both sides of the frame 1 to make the weft yarn bounce back and forth put, so that the weft yarn is tightened between the pressure plates on both sides of the frame. After the weft yarn of the scarf is tightened, the small split plate is instructed to rise, and the split teeth of the small split plate will tighten the weft yarn Divide the thread into small strands of equal parts, and then operate the lifting and translation device 14 to lower the upper washboard 12 until it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com