Oral implant abutment and manufacture method thereof

A technique for oral implants and abutments, which is applied in the field of medical implants, can solve problems such as easy-to-adhesive plaques, and achieve the effects of reducing plaque adhesion, facilitating tight enveloping, and good functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] Firstly, it is explained that the surface roughness in the embodiments of the present invention is Ra, that is, the arithmetic mean deviation of the profile.

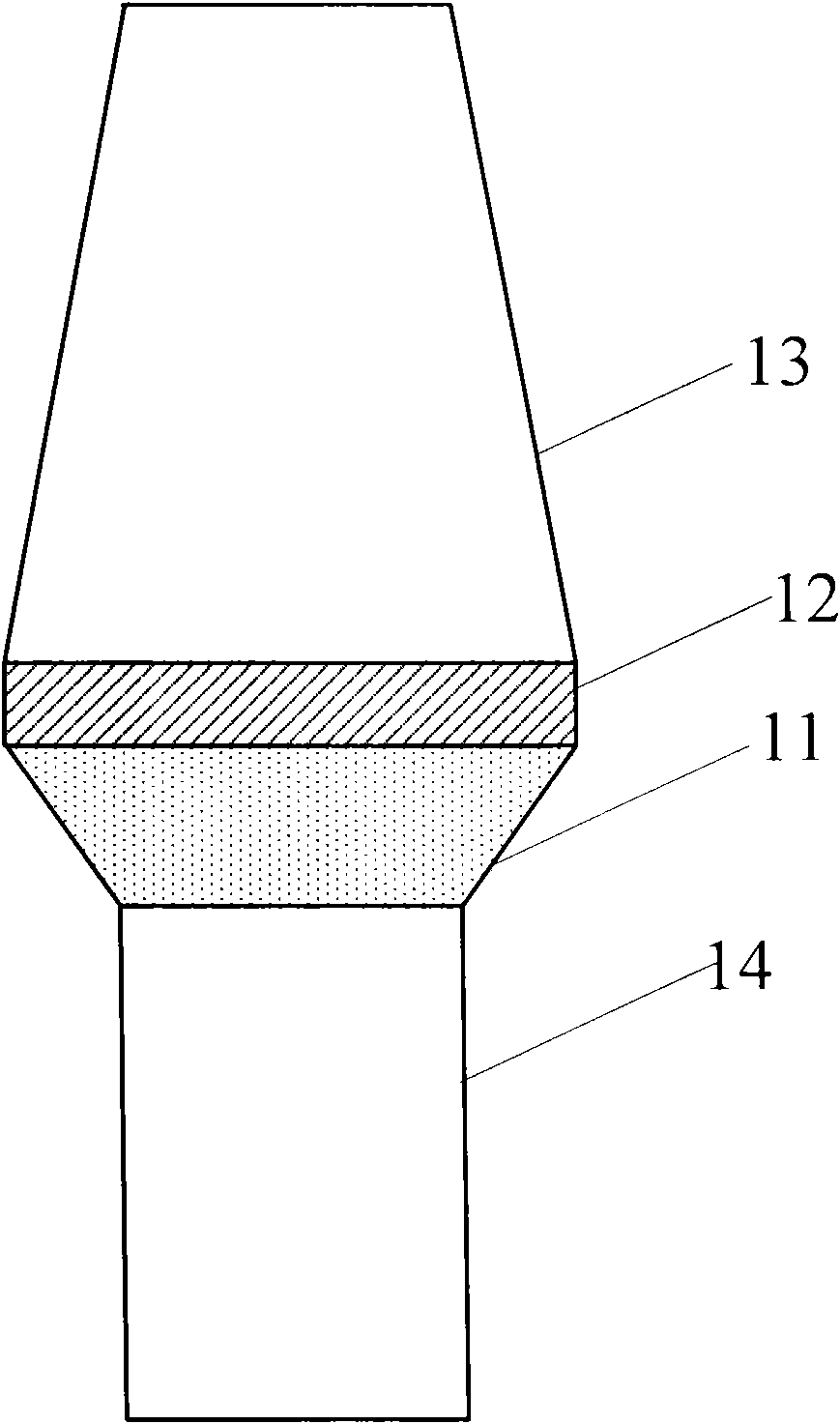

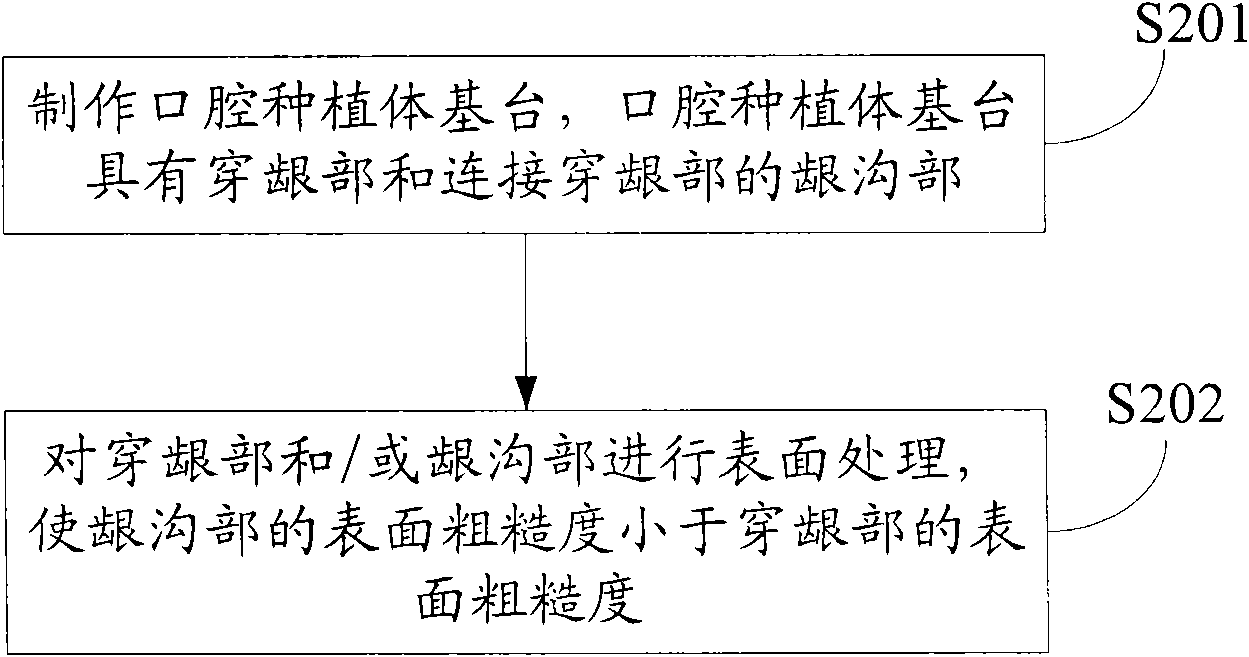

[0031] Such as figure 1 , an oral implant abutment provided by an embodiment of the present invention, comprising:

[0032] Transgingival 11;

[0033] The gingival sulcus portion 12 having a surface roughness smaller than that of the gingival portion 11 is connected to the gingival portion 11 .

[0034] Among them, the transgingival part 11 is used to combine with the gingival tissue to form a soft tissue seal; the role of the gingival sulcus part 12 is similar to the shoulder of a natural tooth, and the edge of the restoration (such as a porcelain crown) ends at the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com