Master welding fixture for aluminum alloy vehicle body

A welding fixture and aluminum alloy technology, which is applied in the field of tooling and fixtures, can solve the problems of large heat deformation, large contact surface between positioning pin and workpiece, and difficulty in taking out the workpiece, so as to achieve the effect of ensuring no damage and controllable welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

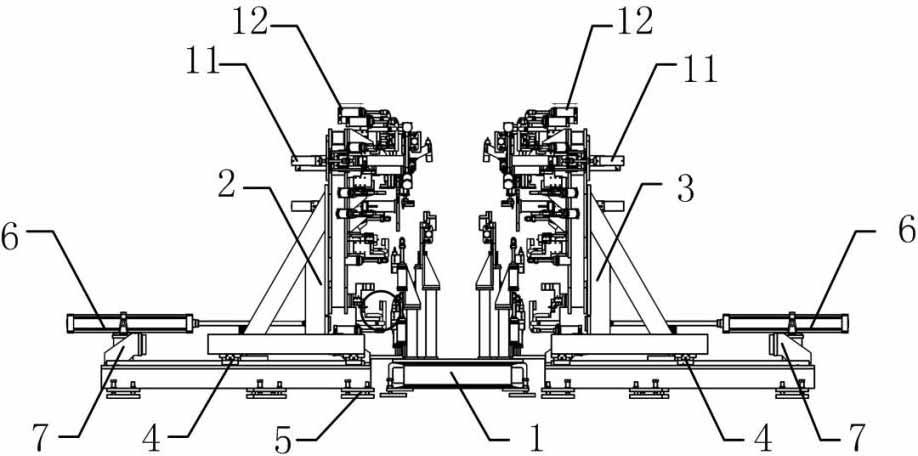

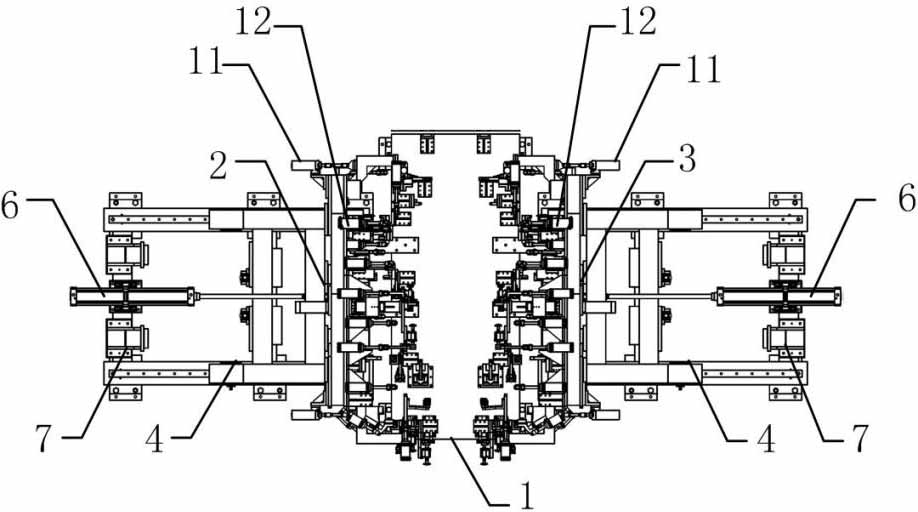

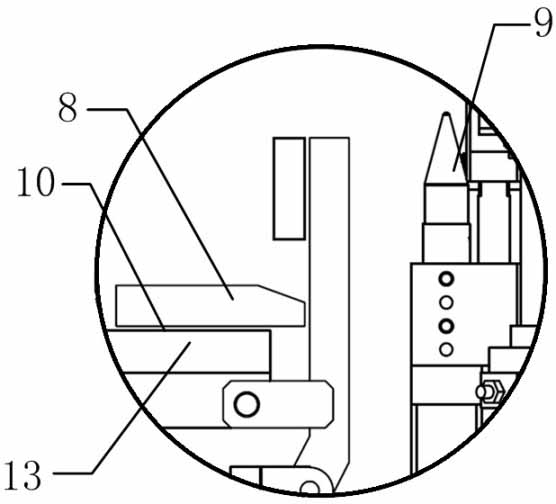

[0016] A kind of overall welding fixture of aluminum alloy vehicle body of this embodiment, such as Figure 1 ~ Figure 3 As shown, it includes a bottom platform 1, a left platform 2 and a right platform 3 arranged on the base platform 1, a horizontal slide rail assembly 4 is provided on the bottom platform 1, and the left platform 2 and the right platform 3 are connected with the bottom platform. 1 are slidably connected by a slide rail assembly 4; the bottom platform 1 is provided with a horizontal adjustment mechanism 5 with a two-way locking function, and the bottom platform 1 is adjusted to a horizontal state and fixed at a specific position, and a locking measure is taken with the ground. so that it does not move. The left side platform 2 and the right side platform 3 are respectively connected with the sliding cylinder 6, and the sliding cylinder 6 drives the left side platform 2 and the right side platform 3 to slide and displace along the horizontal direction; The sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com