Template system of prefabricated simply support box beam

A box girder and simply supported technology, which is applied in the field of formwork and prefabricated tooling systems, can solve the problems of beam body affected by camber and low appearance quality of beam body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described:

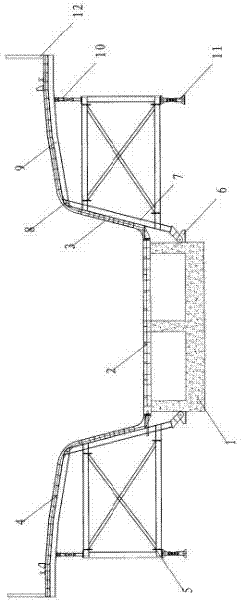

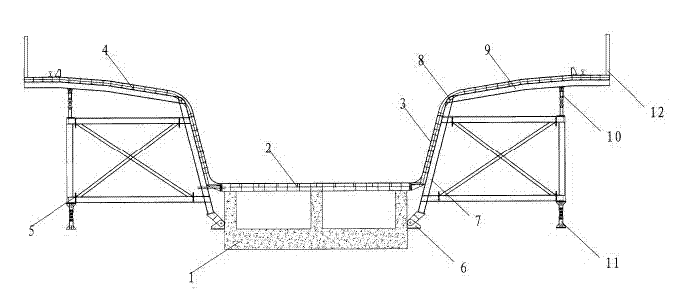

[0011] The formwork system of the prefabricated simply supported box girder, including strip girder pedestal 1, prefabricated simply supported box girder, bottom formwork 2, side formwork 3, end formwork and inner formwork, connected on the embedded parts on strip girder pedestal 1 There is an I-beam, on which a bottom formwork 2 is arranged, and the bottom formwork 2 is assembled in pieces by bolt connection, and side formwork connecting hinges 6 are arranged on both sides of the bar-shaped beam pedestal 1, and the side formwork The lower end of the support adjustment plate 7 is hinged with the side formwork connecting hinge 6, the upper end of the side form support adjustment plate 7 is hinged together with the inner end of the flange support adjustment plate 9 through the two plate connection hinges 8, and the side form support adjustment plate 7 The outer side of the outer mold truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com