Film processor

A technology of thin film processing and processing machine, which is applied to other household appliances, flat products, household appliances, etc., and can solve the problems that mechanical equipment cannot meet the process requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and example the present invention is further described.

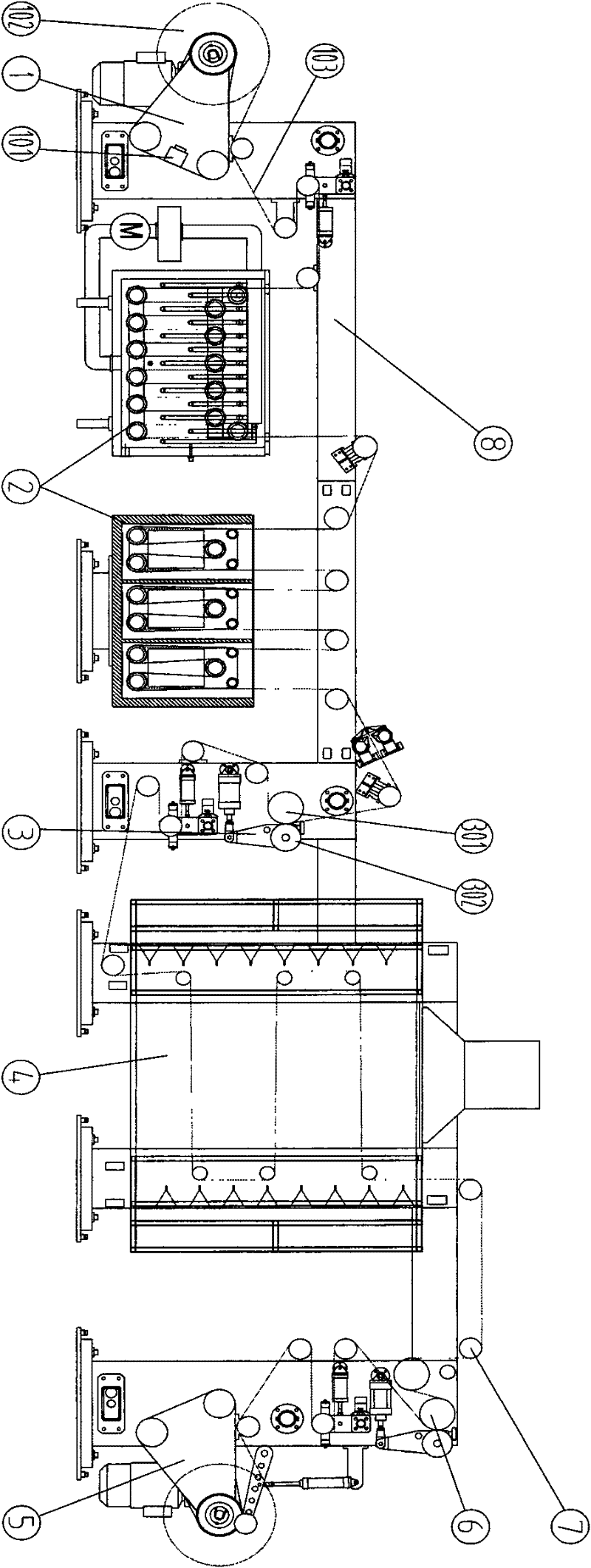

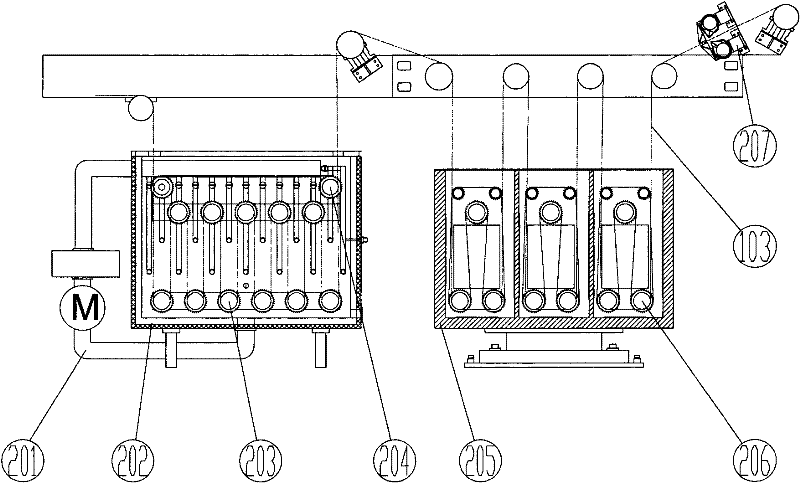

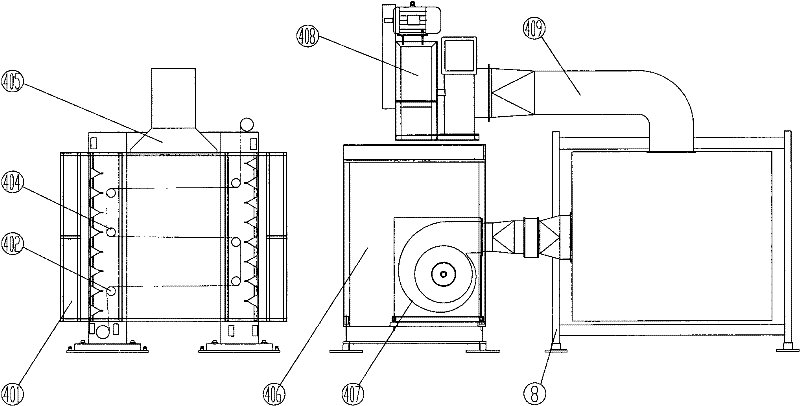

[0014] Please refer to figure 1 , in the present invention, the film material roll 101 is placed on the unwinding mechanism 1, and the correction device 102 on the unwinding mechanism 1 adjusts the film material roll 101 longitudinally; , enter the treatment tank one 201 in the film treatment mechanism 2, after preliminary treatment, the film 103 walks around the guide roller 7 above the treatment tank I 201, enters the treatment tank two 205 for the second treatment, in the treatment tank two 205 Above the outlet, an air knife mechanism 207 is installed to blow away the treatment liquid on the film 103 against the running direction of the film 103 to remove most of the treatment liquid on the surface of the film 103 . The processed film 103 is wrapped on the traction mechanism 3, and the traction pressure roller 302 presses the film 103 on the surface of the tracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com