Roll-to-roll laser holographic image embossing transfer production line and production process thereof

A laser holography, production line technology, applied in printing, printing machine, transfer printing and other directions, to achieve the effect of high degree of automation, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

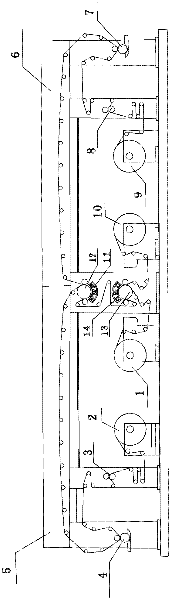

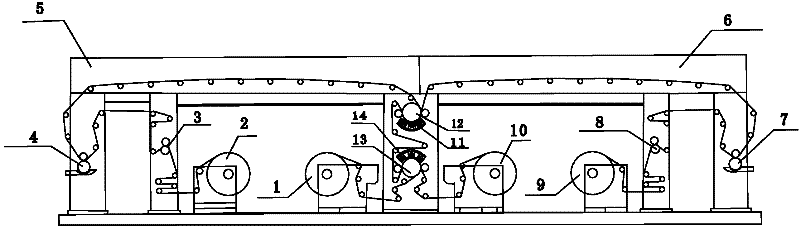

[0017] like figure 1 The roll-to-roll holographic image imprint transfer production line shown is composed of the following components: a printing film unwinding device 2 located on one side of the production line and arranged in sequence according to the printing film conveying direction, a printing film traction device 3, and a printing film coating system 4. Printing film drying channel 5 and printing film winding device 1; holographic BOPP film unwinding device 9, holographic BOPP film traction device 8, holographic BOPP film coating located on the other half of the production line and arranged in sequence according to the conveying direction of holographic BOPP film System 7, holographic BOPP film drying tunnel 6 and holographic BOPP film winding device 10; the first holographic embossing device 12 and the second holographic embossing device 13 located in the middle of the production line, the second holographic embossing device 13 is located in the first holographic embos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com