Circulating feeding device

A technology of feeding and transmission devices, which is applied in the direction of transportation, packaging, and conveyors. It can solve the problems of low degree of automation, small storage of materials, and affecting production efficiency. It achieves a high degree of automation, improves production efficiency, and saves labor. The effect of spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

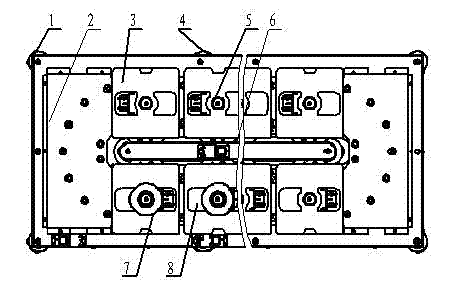

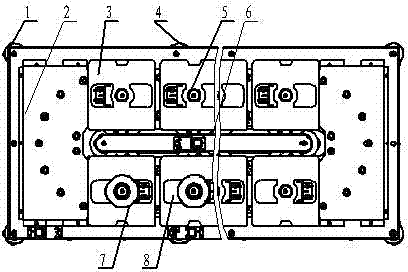

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the present invention includes a frame 1, two roller seats 2 are fixedly installed at both ends of the frame 1 respectively, a base plate 3 is movably connected to a transmission device 6, a guide pipe 5 is fixedly connected to a base plate 8, and a retaining tube 8 is fixedly connected On the base plate 8; the workpiece 7 is set on the guide pipe 5; the shock absorbing pad iron 4 is fixedly installed on the frame 1, which can effectively reduce the vibration; A lot of material.

[0014] When the present invention is in use, when there is no workpiece 7 on the guide pipe 5, the transmission device 6 drives the bottom plate 3, the retaining pipe 8 and the guide pipe 5 to move together to the position where the workpiece 7 is grabbed, and the cycle is like this to realize automatic loading. material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com