A continuous extrusion production process of water-cooled strips for battery packs

A production process and water-cooled belt technology, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult production, no forming process, and high technical content, and achieve the effect of high qualification rate, lower energy consumption, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

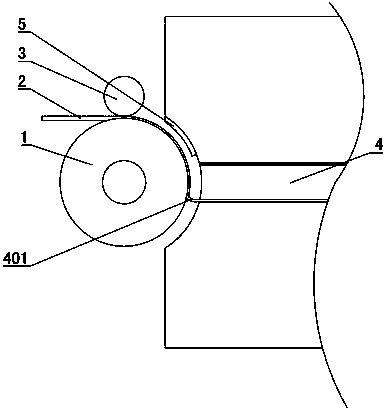

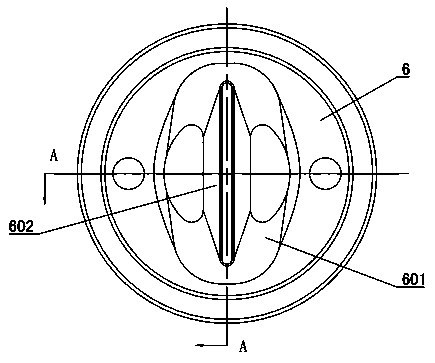

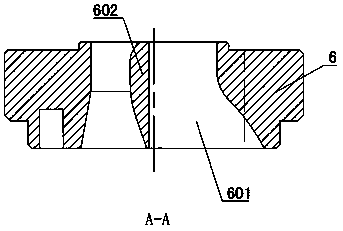

[0037] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0038] The aluminum material 2 is extruded by a Conform continuous extrusion machine. The extruder includes a sheave 1 for conveying the aluminum material 2, a cavity 4 on one side of the sheave 1, and a cavity 4 arranged between the sheave 1 and the cavity 4. Between the material guide plate 5, the material guide plate 5 is an arc coaxial with the sheave 1, a mold is provided in the cavity 4, and the mold includes a connected upper mold 6 and a lower mold 7 and a mold set in the upper mold 6 The mold core, the upper mold 6 is provided with a feeding hole 601, the lower mold 7 is provided with a forming hole 703, the feeding hole 601 communicates with the forming hole 703, the mold core is arranged in the middle of the feeding hole 601, and the rear side of the mold core is arranged at intervals There are mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com