Spiral winding type accumulator storage device

A spiral winding and looper technology, which is applied in packaging, thin material handling, coiling strips, etc., can solve the problems of high manufacturing precision, scratches on the surface of the steel strip, and large investment in equipment, and achieves low manufacturing precision requirements. High efficiency, lower processing difficulty, more storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

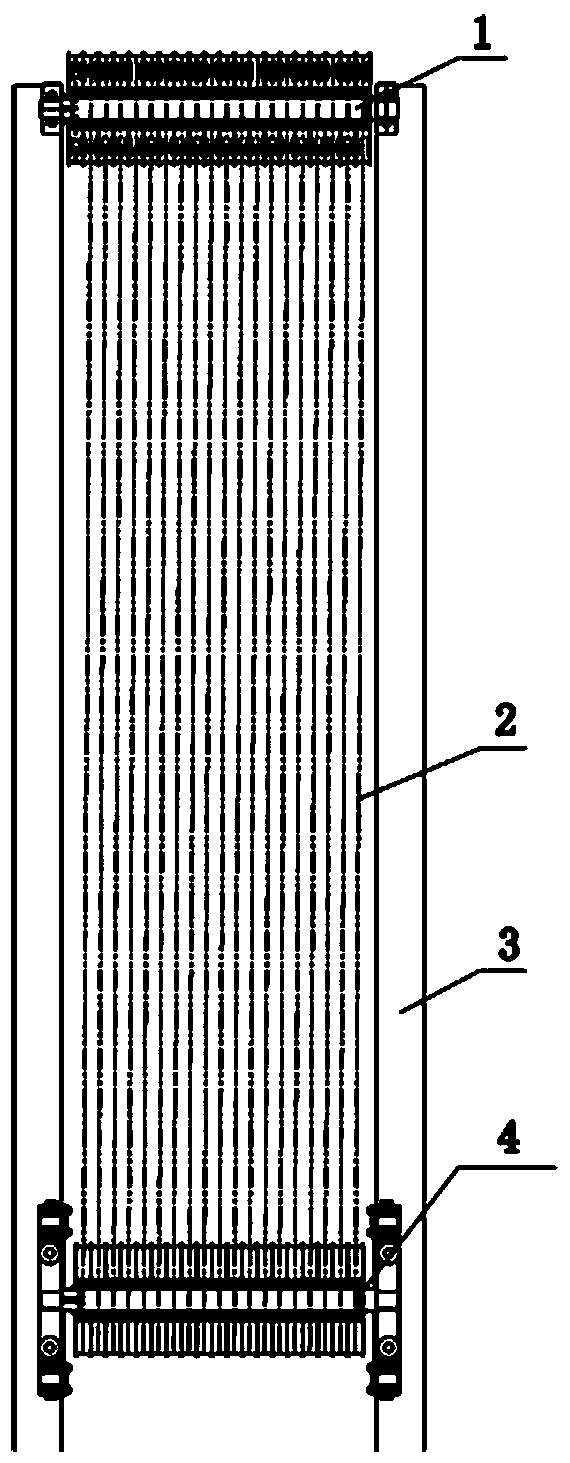

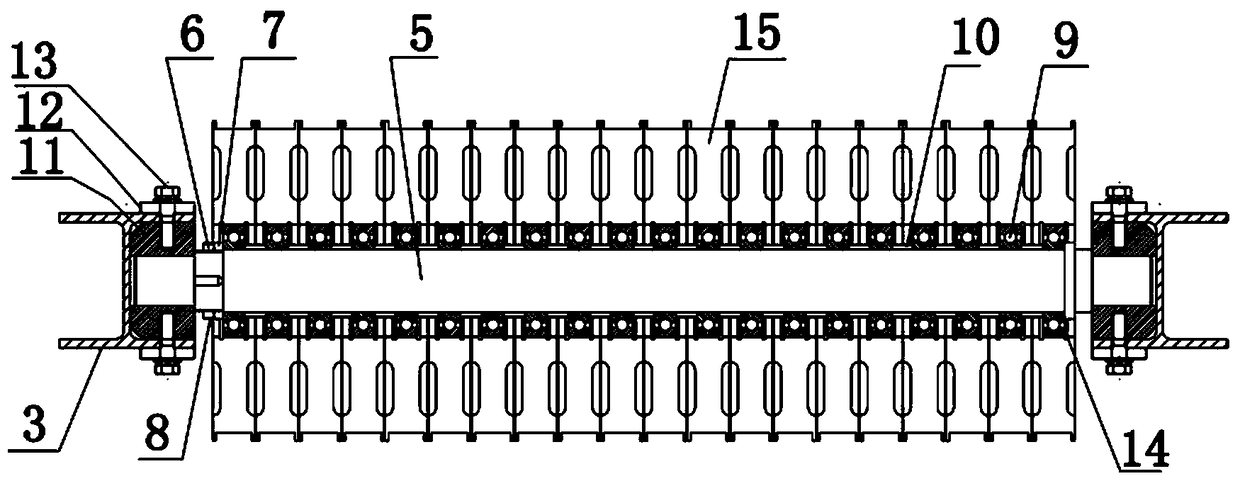

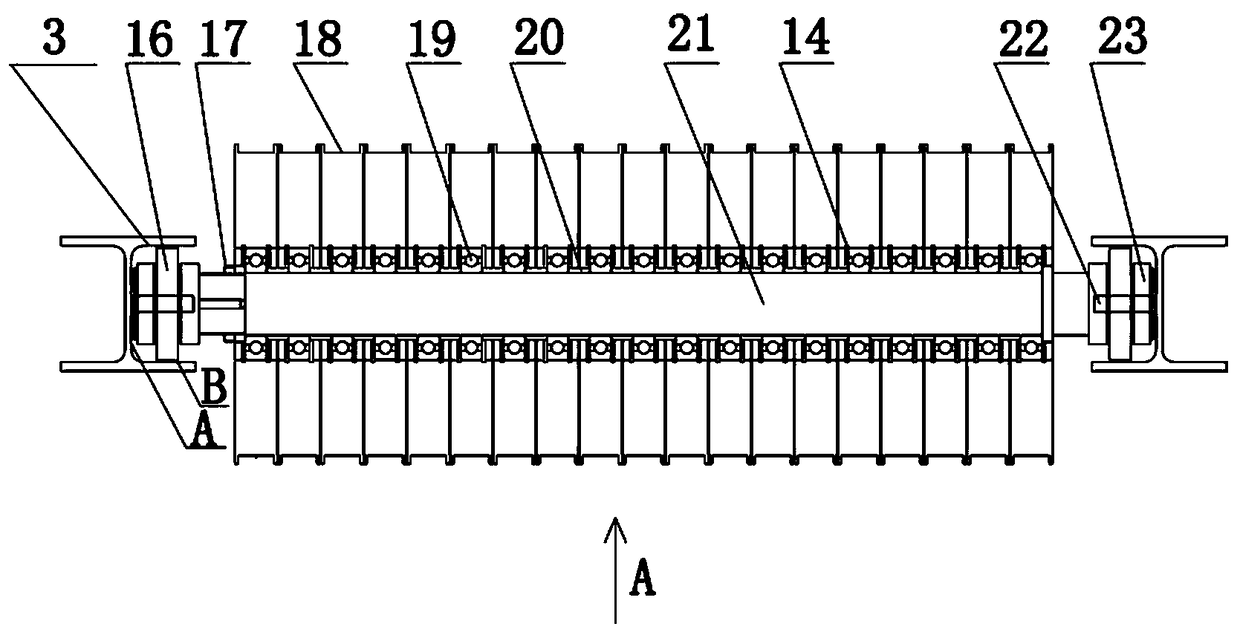

[0025] Such as Figure 1-5 As shown, the spiral winding looper material storage device of the present invention is characterized in that it includes a device frame that is obliquely arranged on the packaging steel strip production line, and is respectively arranged on the chutes inside the two columns 3 of the device frame, and is arranged on the device frame. The upper looper fixed roller 1 on the upper part of the frame is arranged below the upper looper fixed roller 1, and the lower looper sliding roller 4 is respectively arranged in the two chutes at both ends. The two columns 3 of the device frame are respectively cross-sectional For the H-shaped frame,

[0026] The upper looper fixed roller 1 includes a main shaft 5, and N upper looper wheels 15 are sequentially arranged on the main shaft 5, and the outermost ends of the N u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com