Torque-limiting type low-speed brake

A backstop and low-speed technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of parts and components overload, reduce the reliability of the backstop of the whole machine, increase the cost of the whole machine equipment, etc., to achieve The effect of improving the safety factor of operation, reasonable and compact structure, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

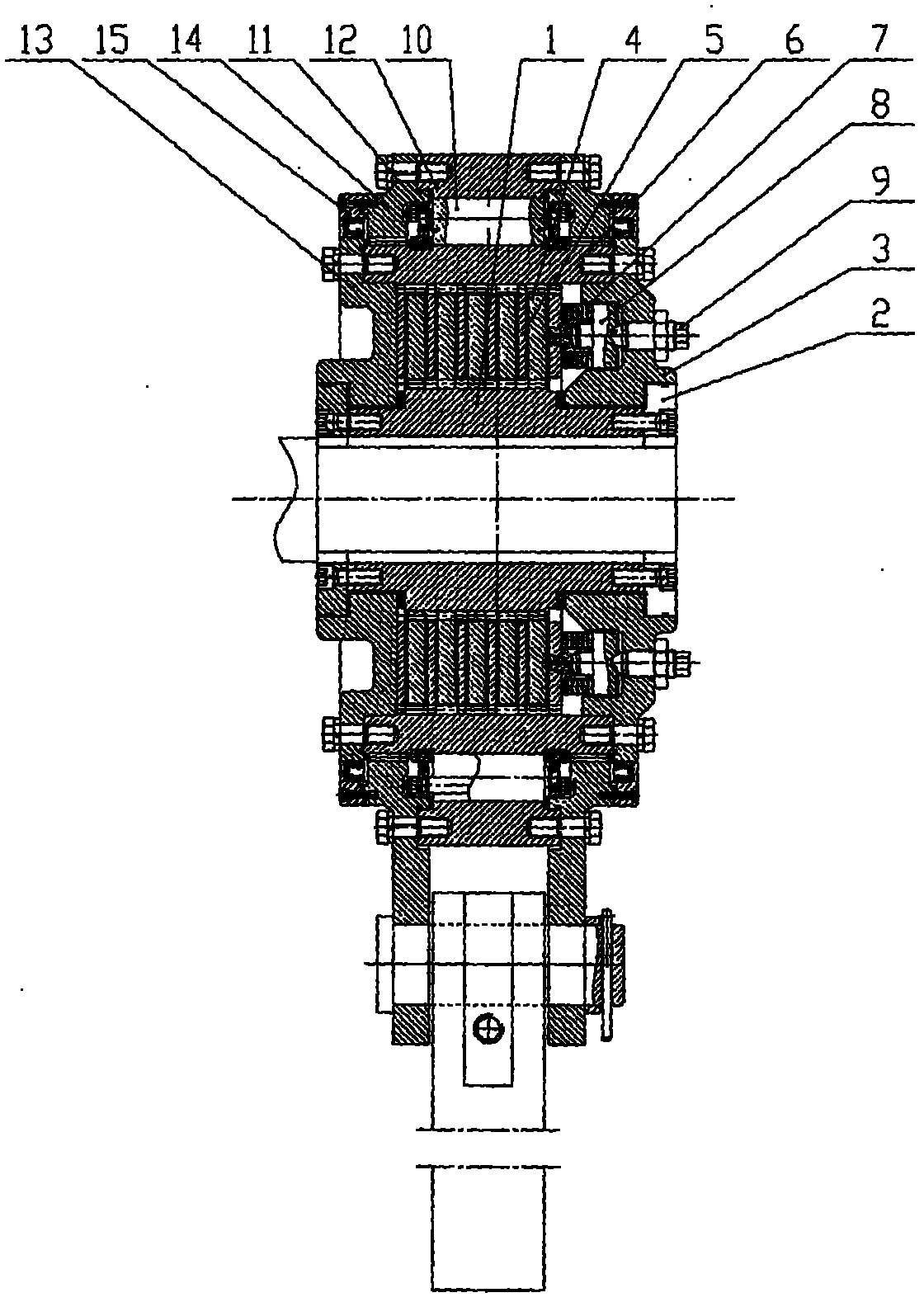

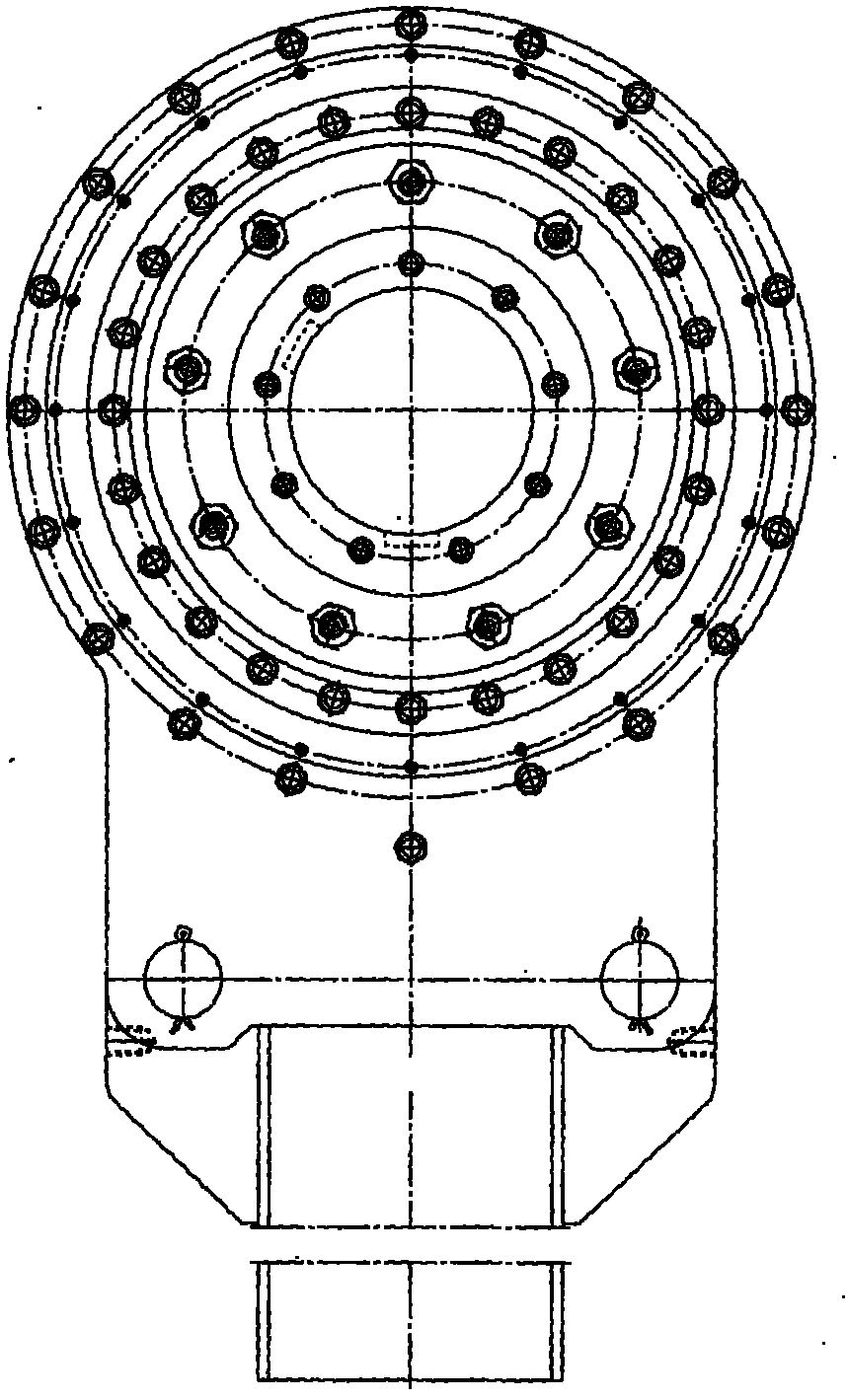

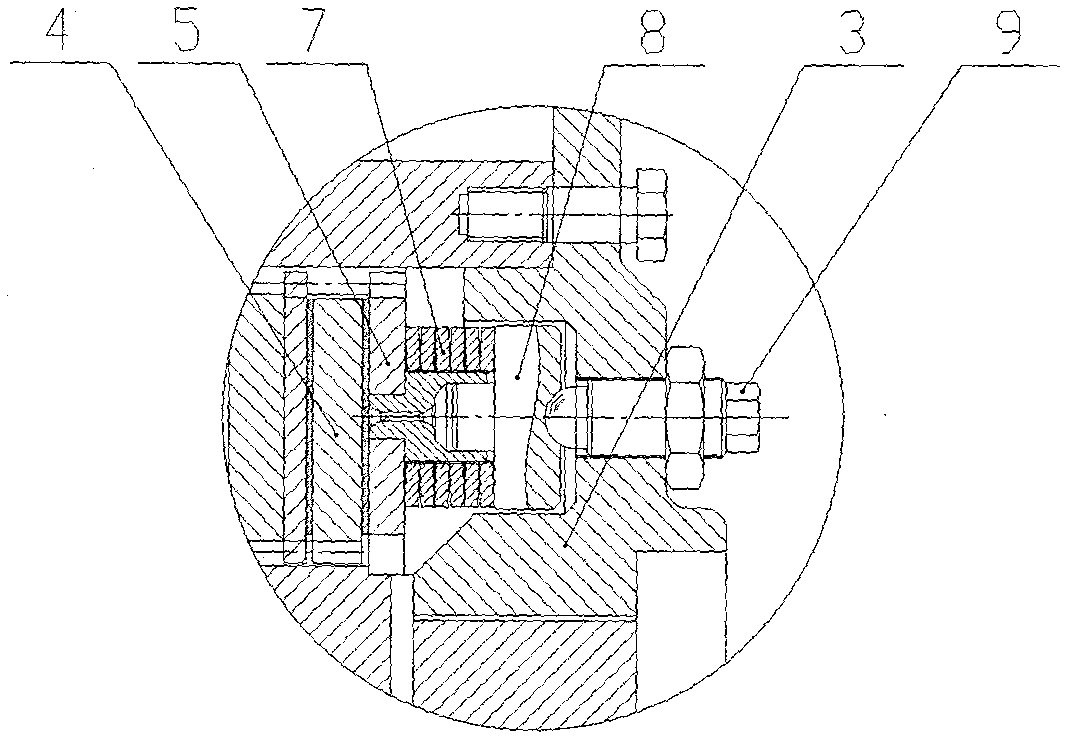

[0012] The moment-limiting low-speed backstop of the present invention, its preferred specific implementation is as figure 1 , figure 2 , image 3 As shown, the torque-limiting low-speed backstop includes active hub 1, pressure plate 2, right support plate 3, dynamic friction plate group 4, static friction plate group 5, driven hub 6, disc spring 7, disc spring pressure block 8, and adjusting screw 9. Roller 10, roller sleeve 11, outer wheel 12, left support plate 13, support plate 14, and oil seal plate 15.

[0013] The driving hub 1 and the pressure plate 2 are connected by bolts, the dynamic friction plate group 4 is embedded with the external teeth of the driving hub 1 through internal teeth, the static friction plate group 5 is embedded with the internal teeth of the driven hub 6 through external teeth, and the driven hub 6 is embedded with The right support plate 3 is connected by bolts, and the driven hub 6 and the left support plate 13 are connected by bolts.

[0014] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap